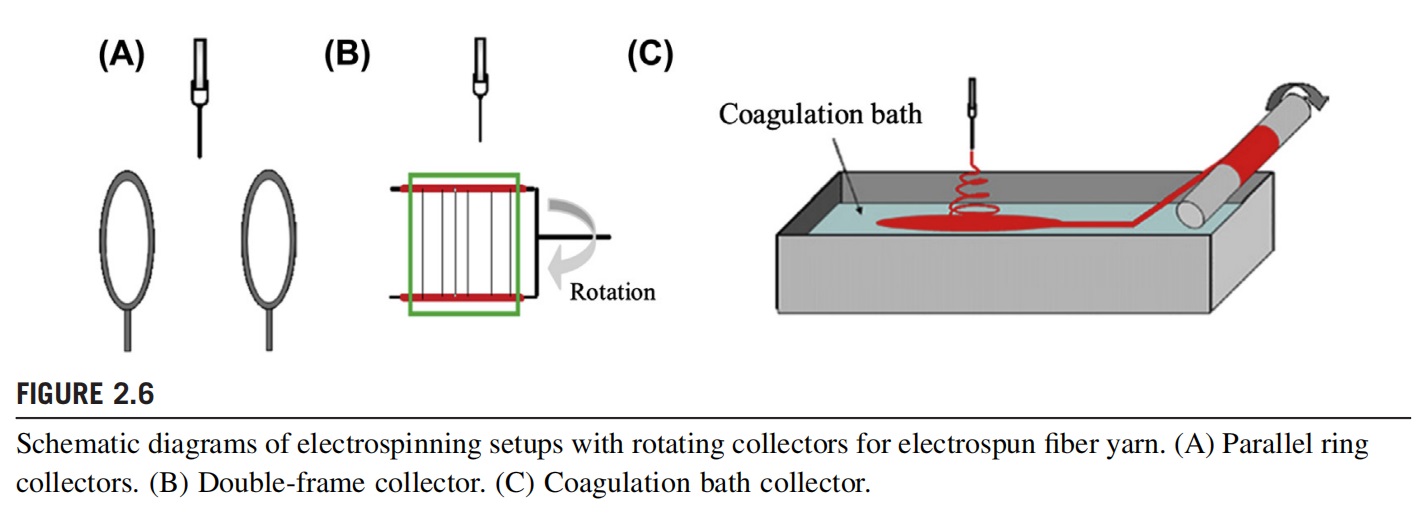

Electrospinning Setups With Rotating Collectors For Electrospun Fiber Yarn

Dalton et al. (2005) reported ring collectors placed in parallel (Fig. 2.6A) to collect electrospun fibers. By this simple setup, twisted yarn with limited length can be fabricated by rotating one of the rings. Zheng et al. (2015) proposed a double-frame collector (Fig. 2.6B) consisting of an inner one (U-shape) and an outer one (rectangle) to achieve aligned and twisted fiber rope. During the electrospinning process, the inner frame is stationary, but the outer one is rotated with the motor. Electrospun fibers are deposited and stretched across two parallel plastic tubes to form excellently aligned fibrous arrays. The pair of plastic tubes with aligned fibers can be removed from the inner frame and transferred to the rotating part of the setup. And one tube is rotated with the motor and the other is fixed to the iron support. Subsequently, a twisted rope can be obtained by rotating the tube connected to the motor.