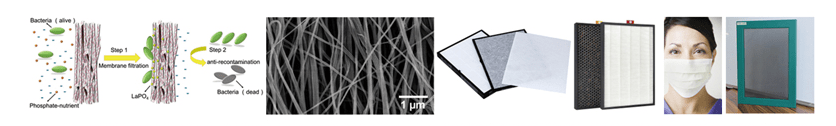

The nanofiber filter material prepared by the electrospinning method has the characteristics of small fiber diameter, small pore diameter of the fiber membrane, and high porosity, which can effectively intercept fine particles with high filtration efficiency and low air resistance. What’s more, electrospinning nanofibers can be easily combined with other functional materials to achieve the functional application of the material. Therefore, the electrospinning nanofiber material has a broad application prospect in the field of filtration.

1. Air Filtration

Due to electrospinning nanofibers have the submicron and nanoscale finer diameter, it has the special pore-channel and cumulate texture, which makes it has many excellent properties, showing its broad application prospect in many fields, especially in air filtration. Compared with current air filtration materials, nanofiber air filtration materials have the following features: fiber diameter with good uniformity, adjustable pore channel and cumulate texture. Due to its good uniformity, electrospinning nanofiber has the relatively uniform to meet the requirement of filtration efficiently of air filtration material.

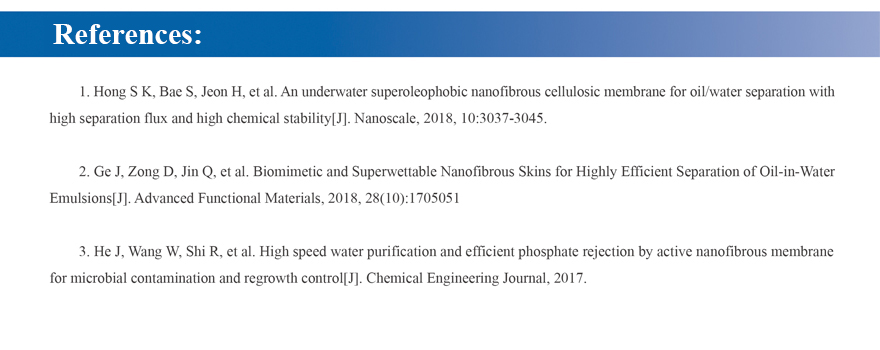

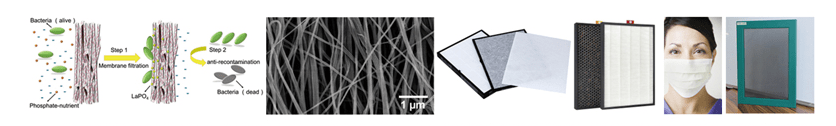

2. Water Filtration

Due to its unique advantages, electrospinning fiber membrane plays an important part in separation application, showing the great property in filtration, especially in water filtration and air filtration. And therefore, it has a great development prospect in membrane separation field. Nowadays, the separation membranes are mostly composite membrane structures. Since the pore structure of electrospinning fibers is relatively scattered and dead holes do not occur, they can be used as the intermediate layer of the composite membrane, and the filtration efficiency of the composite membrane is greatly improved.

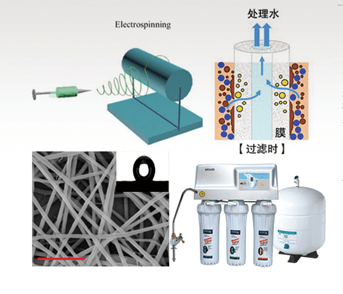

3. Oil-water Separation

The treatment of oily wastewater mainly includes physical diffusion methods, solidification methods, gravity separation methods, etc. However, on the one hand, these methods cannot effectively recover oil spills, and there is a problem of secondary pollution during the treatment. On the other hand, since most of the oil-containing wastewater exists in the form of an emulsion, and the droplet size of the emulsified oil droplets is small, generally from nanometers to several micrometers, the above methods are difficult to remove, and the energy consumption is high. The composition of emulsified oil wastewater is complex and has a certain degree of inertia, which seriously damages the water environment and human health. Therefore, the advantages of the electrospinning method are outstanding, and it is possible to produce a nanofiber membrane with superhydrophobicity, small diameter, and high strength.