What is the fuser film sleeve? Fuser film sleeve is a special high temperature resistant film used for copier or printer for fixing during copying or printing. Fixing is the process of fixing an unstable, erasable toner image on the copy paper to the paper, usually through fixing. After the component is heated, the toner is melted and then penetrates into the deep layer of paper fiber, which is the effect of copying or printing.

|

How the fuser film sleeve and the fuser heat roller work? When the paper passes through the printer's fuser (fixing roller), the loose toner will melt and fuse with the fibers in the paper; then the fuser conveys the paper to the output tray, and you get the final printed page. In addition, the fuser heats the paper itself, which is why the paper coming out of a laser printer or photocopier is always hot.

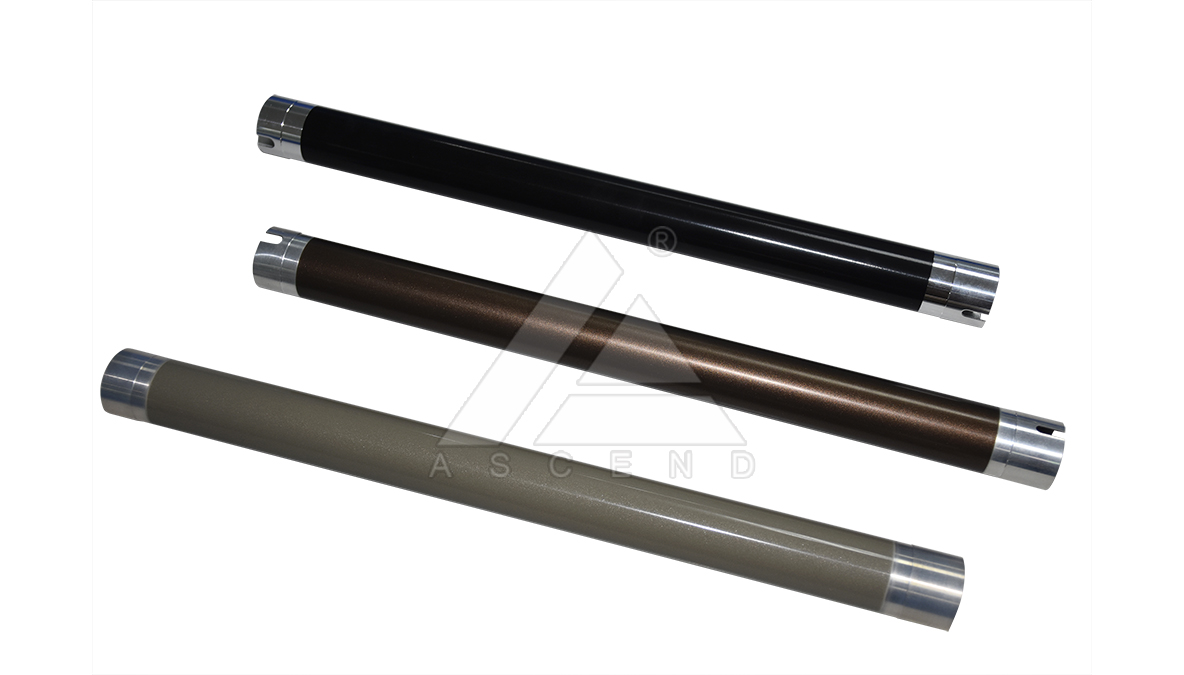

Fuser Heat Roller Why does the fuser film sleeve replace the fuser heat roller? The printer is generally powered on all day, especially the all-in-one machine is in working state for 24 hours; if the fuser roller is used, the thermal inertia is large, the power consumption is large, and the heat inside the machine is not easy to radiate. In order to reduce the warm-up standby time and achieve zero start, an extremely thin film is used instead of the Fuser Heat Roller.

|

Fuser film sleeve structure and performance requirements The structure of the fixing film is: base layer + thermal conductive layer + surface coating Performance requirements: ① Toughness can reach more than 50 times ② Uniform thickness ③ The inner wall is smooth, no noise, no burrs ④ The thermal conductivity standard should reach 240-320 degrees ⑤ The port is neat and free of burrs ⑥ There are no spots, no burrs, no creases and no marks.

|