Qingdao Glory Footwear Co., Ltd., as a professional safety shoes manufacturer, always maintain close contact with clients, listen to their feelings about products, expect product protection requirements, and work with them to study labor protection solutions, together to meet the new challenges brought about by the development of the industry.

Safety shoes are one of the important protective articles with a wide range of uses. At the production or engineering site, the ground conditions are complex, and people are easily punctured by sharp objects, slipping, electric shock or being injured by heavy objects. At this time, safety shoes are required. To provide protection, many engineering and production sites require safety shoes. There are many types and how to choose? We are willing to share our experiences with you.

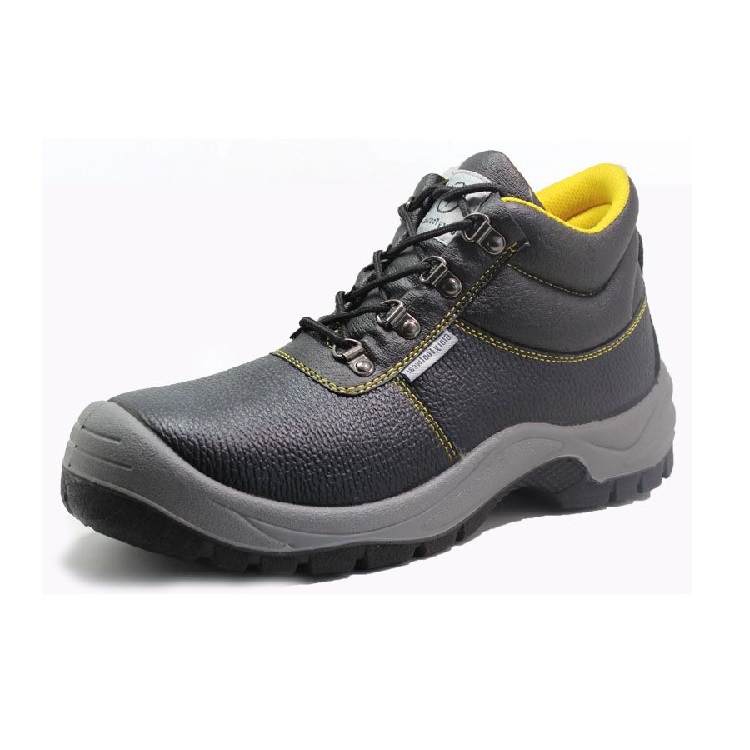

The first consideration is to meet performance. The appearance of general safety shoes is similar. The difference in performance of most safety shoes is reflected in the sole. The ground environment requirements determine the sole material. For example: casting, high temperature processing and other environments will make the ground temperature in the work area very high. High, need to use high temperature rubber soles. Industries such as mechanical processing often make the ground splashed with oil stains, which are particularly slippery. A non-slip PU sole is required to prevent slipping. There are sharp objects on the ground such as nails, glass, metal shavings, etc. in the mining, firefighting, construction, forestry, cold work, machinery industry, etc. At this time, the soles need to be added with steel plates to prevent puncture, electricians, electric operators, cable installation Workers, substation installers, etc. have the risk of electric shock, need to insulate the soles, and the working environment should keep the uppers dry. Avoid contact with sharp objects, high temperature and corrosive substances, and the bottom must not be damaged by corrosion. Gas station operators, liquefied gas filling workers, petrochemical company employees, there are flammable and explosive materials around, static electricity may cause fire and explosion, and safety soles need certain conductivity to prevent static electricity accumulation. If there are no special performance requirements, ordinary work positions only require anti-smashing, then use PU soles, light and soft, comfortable to wear.

Glory Footwear needs a detailed understanding and research on the working environment and customer requirements before determining the customer's product type and wearing method. After a comparative evaluation, the final use plan is determined. Welcome friends from all over the world to negotiate business and look forward to our cooperation.