At present, in agriculture, food, chemical industry, ceramics industry, medicine, mineral processing, pulp and paper making, wood processing and other industries, almost all production processes need drying. The quality of drying materials depends on whether the constant temperature is well controlled. The heat pump drying technology is a mild and natural drying method, which is more suitable for drying most of the agricultural products, medicinal materials and other heat sensitive materials.

It is worth mentioning that drying is also a high energy consumption process. Data show that the energy consumed for drying in most developed countries accounts for 7-15% of the total national energy consumption, while its thermal efficiency is generally less than 50%. Air source heat pump can become a "magic weapon" in the drying field, naturally it can not be separated from its "unique skills". Because the air source heat pump relies on the heat in the air to output, the first-degree electricity can carry the heat equivalent to the fourth-degree electricity, and the heating efficiency is equal to four times of the direct-heating equipment, or even no less than coal-fired.

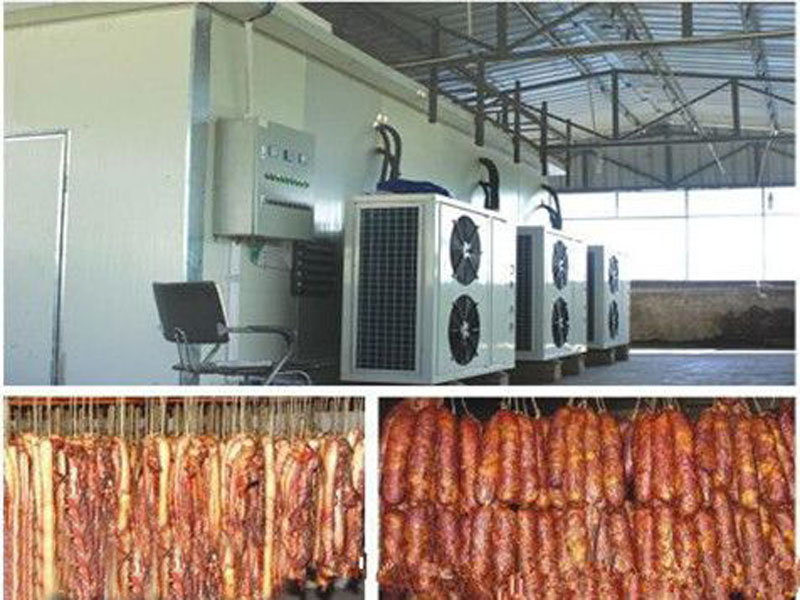

The principle of heat pump dryer is to use the reverse Carnot principle. The gas is compressed by compressor to become high temperature and high pressure gas (temperature up to 100 C). It enters the heat exchanger (condenser) on the indoor side, and the condensate liquefaction releases high temperature heat to heat the air in the drying room. The materials in the drying room vaporize and evaporate the water in the materials through hot air. The evaporated water vapor is discharged from the dehumidification system to achieve the purpose of drying materials. Heat pump dryer can get more energy from the air by consuming only the electric energy used by the compressor when it works. The energy efficiency ratio is as high as 400%, which is more energy-saving than other drying methods.