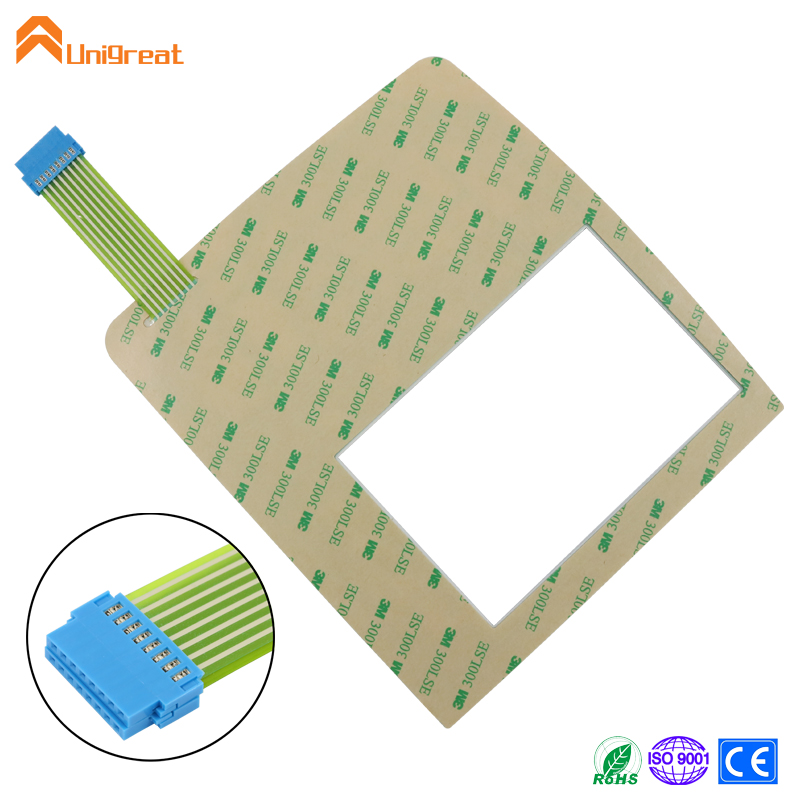

Today, Shenzhen Unigreat Technology Co., Ltd. has become the leader of Chinese membrane switch industry. Unigreat Technology's capacitive sensor series contains multiple sub-products. A quality assurance system is instituted to demonstrate compliance with the requirements of standards. It has more advantages compared to other competing products.

We are putting our efforts to protect resources and ecosystems. For example, we aim to reduce CO2 emissions by constantly improving the quality of discharge.