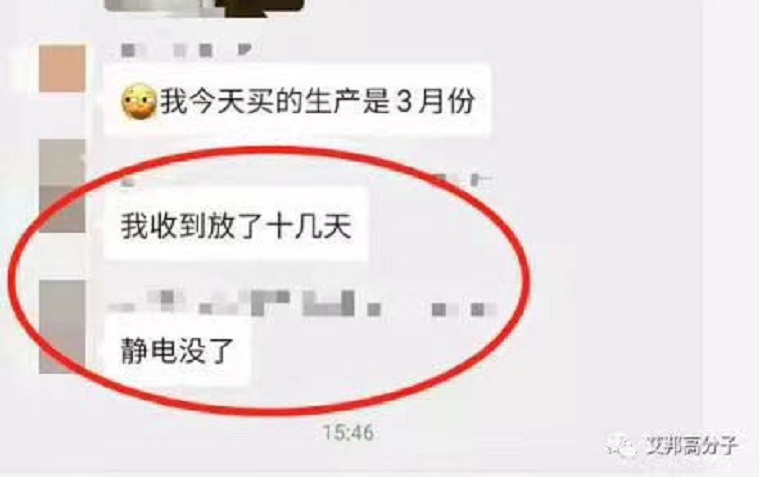

The customer reflects the shortcoming of melt-blown cloth on the market: so-called filter efficiency 99% melt-blown cloth, 10 days lost filter efficiency completely. In the factory, the melt-blown cloth can be glued to the hand. But after a few days, only about 30% of the filtering effect is left!

We consulted professionals and they said there are surface charges and body charges. Body charge is easier to last. Surface charge, more on the surface. For example, the filter material made performed very well in the previous test and stuck to the hand. However, the surface charge also tends to decay, making the filter effect less persistent.

Qingzi Nano's equipment produce nanofibers membranes as the mask filter. No need to do electret treatment, longer service life, more skin-friendly bonding, suitable for long-term wear.

How to establish differentiated products of masks in the post-epidemic era? Choosing electrospinning technology is the most economical and fastest way to establish differentiated products.

How to use electrospinning technology to make differentiated products?

1. Endow the mask with antibacterial and bactericidal properties, up to 99.95% antibacterial properties can be reached.

2. Make some masks with auxiliary therapeutic functions. For example, adding relevant traditional Chinese medicine preparations into the nanofibers can make the mask have such as auxiliary treatment of rhinitis, motion sickness, respiratory tract related chronic diseases and other related chronic diseases. Or add some refreshing substances, so that the use of masks more comfort customers.