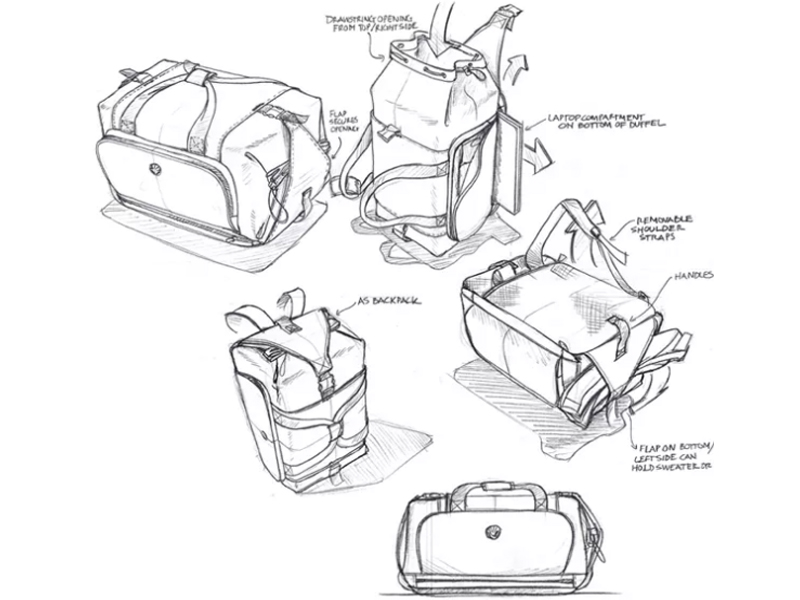

I. DESIGN

Design diagram is the first step of bag design, should be able to reflect the design concept, fashion trend, market prediction, materials used, color, size and other conditions.Is the performance of the designer's creation of the premise information.We have been in-depth and detailed analysis of consumer psychological needs, will design works of practical success in front of the artistic conception.Bag design belongs to the category of art and practical design, which is generally composed of three directions: material selection, color matching and design。

1) Material selection: material selection is also the basis of bag design. Natural leather, PU fabric and composite material are the main fabrics of bag products, which reflect the performance and style characteristics of the whole bag.

2) Design of style: the design effect drawing takes drawing, sketch, color, pattern and other artistic basis as the basic quality requirements. The rendering should fully reflect the gloss and texture of leather materials.

3) Color collocation, any form of clothing must be able to express through color.Such as the gorgeous sense of color, elegant sense, active sense, , expansion sense, contraction sense.Color has a rich expression, can convey a certain emotional charm, and convey the emotional reflection of the information.

2, open paper Pattern

In bag design, the second step is to make the model according to the Artwork with good design, design extension on the template paper carefully, if symmetrical components, such as fan, wall, cover and the bottom of the bag bag, only need to draw an outline of the half, then, the symmetry axis trace or other pointed instruments with the awl, and along the symmetry axis can be folded in half to complete the other half, will be folded in half, cut the parts.

Due to the fat surface of the inclusion, we need a curved sheet, which is similar to cylinder surface in life.Surface unfolding is the unfolding of a curved surface of an object into a flat surface of its actual shape and size.

3.Cutting

Cutting Material is the first step in the production of bags. The quality of material opening directly affects the quality of products and the cost of products.Therefore, cutting is one of the more technical processes.The steps of material opening are etching, polishing, waxing, punching, molding, punching, cutting, assembling, forming, forming, bending, hot pressing

1)selection: spread the leather on the table, check the quality of the leather, the disabled parts and can be used, according to the quality of the file.

2) Discharging: when discharging, main fabrics such as fan, wall, plug and cover are generally arranged first, and then small materials and secondary components are arranged.

3) delimit the sample: after the leather sheet has been selected to approve, the sheet skin tile on the platform, will need the sample shop, and check whether the disability on the leather surface can be used and evasive.

4) Cutting sample: there are two ways to cut sample, one is to cut with scissors, the other is to cut with a cutting knife.

5) bulk production will be cutting by machine and mold

4.Table work

Table technology is divided into four categories:

1) Chipping process: chipping is to make the edges of parts and components of products chipped into certain specifications according to the technological requirements, so as to meet the requirements of the next process.We must ensure that zero, parts of the joint, folding, pressure recommendations, plain clothes, neat, beautiful, avoid because of zero, parts of the seam, folding, pressure recommendation parts too thick, affect the quality and appearance of products.

2) Modification and inlaying of parts' edges: the modification and inlaying of parts' edges are widely used in cases and bags.Edge modification and splicing are carried out on the basis of edge.It is also the basis of suture.The trimming of the edge usually includes dyeing edge, folding edge, edging, piping edge, raising edge and so on.

3) Adhesive technology: adhesive technology refers to the fabric and the box or lining through the adhesive into a process.The bonding process can be divided into three - dimensional parts of the bonding and the plane parts of the two types of bonding.

4 .Basic sewing process: stitching is the main means to connect parts and components of products.It is through stitching that scattered parts and components can be assembled into a complete product. The stitching process is the main part in the operation of luggage and bags.

5.Clean and repair

After each step of processing, the product is likely to be contaminated in the production process, which needs to be cleaned and rubbed. At the same time, due to the requirements of modeling and design, a series of modifications and finishing work are required.Including: cleaning, plastic, repair, repair, hardware accessories, anti-corrosion treatment.Most packaging into finished products.