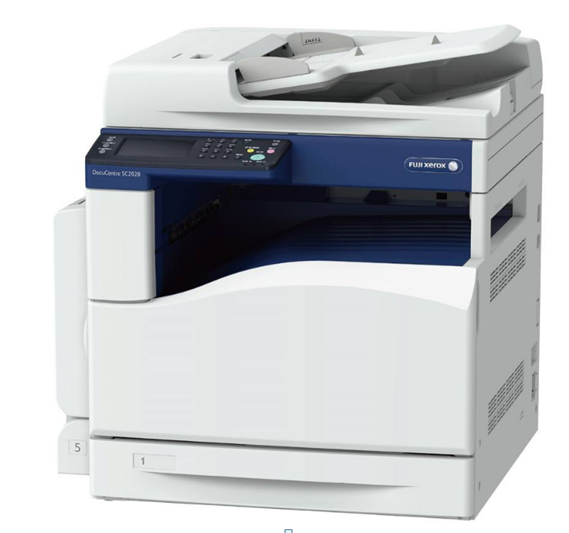

What we usually call a copier is an electrostatic copying machine, which is a device that uses electrostatic technology to copy papers. The copier has a fast copying speed and is easy to operate. The main difference from the traditional typeface printing, stencil mime printing, offset printing, etc. is that the copying can be obtained directly from the original without intermediate means such as other plate making. It is more economical when the number of copies is small. Origins of the copier In the pre-photocopier days, duplicate copies of a document were usually made at the source, either by using carbon paper or manual duplicating machines. People were happy with how things worked, and no one really thought that a photocopier could ever exist. However, Chester Carlson, the man who invented the photocopier, had different plans for the world. He was actually a patent attorney, and only a part-time inventor. His work at the New York Patent Office required him to make multiple copies of important documents, which he not only found extremely tedious and boring, but also discomforting, as he suffered from arthritis. He conducted experiments of photoconductivity in his own kitchen, made the first crude design of a copier, and applied for a patent in 1938. He then approached numerous companies, including General Electric and IBM, all of which turned him down, citing that since there were already a few methods available to make duplicate copies of documents, no one would be interested in buying a copier. He conducted experiments of photoconductivity in his own kitchen, made the first crude design of a copier, and applied for a patent in 1938. He then approached numerous companies, including General Electric and IBM, all of which turned him down, citing that since there were already a few methods available to make duplicate copies of documents, no one would be interested in buying a copier.

|

A photocopier works on a ‘dry’ photocopying technique, as it does not use any liquid chemicals. (Photo Credit : hc360)

| Parts of a copier A typical photocopier (also casually known as a ‘xerox machine’) consists of the following components: A photoreceptor drum (or belt), which is covered by a layer of a semiconductor material, such as selenium, silicon or germanium. This is arguably the most critical part of the machine. A toner, which is basically just pigmented liquid. Sometimes referred to as ‘dry ink’, a toner is a dry mixture of fine, negatively-charged plastic particles and coloring agents that create the duplicate image on a piece of paper.

|

Color Laser Printer toner cartridges (Photo Credit : Flickr)

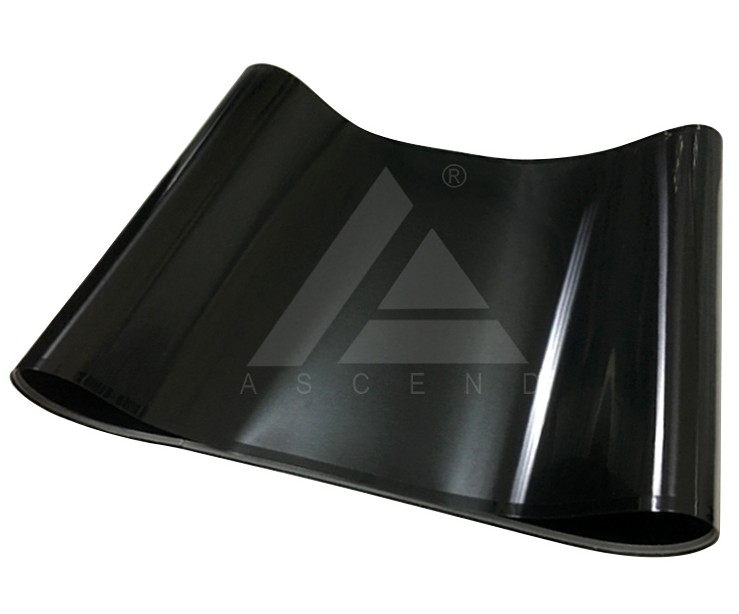

A transfer belt is a transfer device whose function is to uniformly transfer toner of four different colors, transfer a toner image formed on a plurality of photoreceptors, and temporarily hold the printer to perform fixing imaging. Mainly used in color laser printers and color copiers. The font is printed onto the transfer belt and the transfer belt is printed onto the paper.

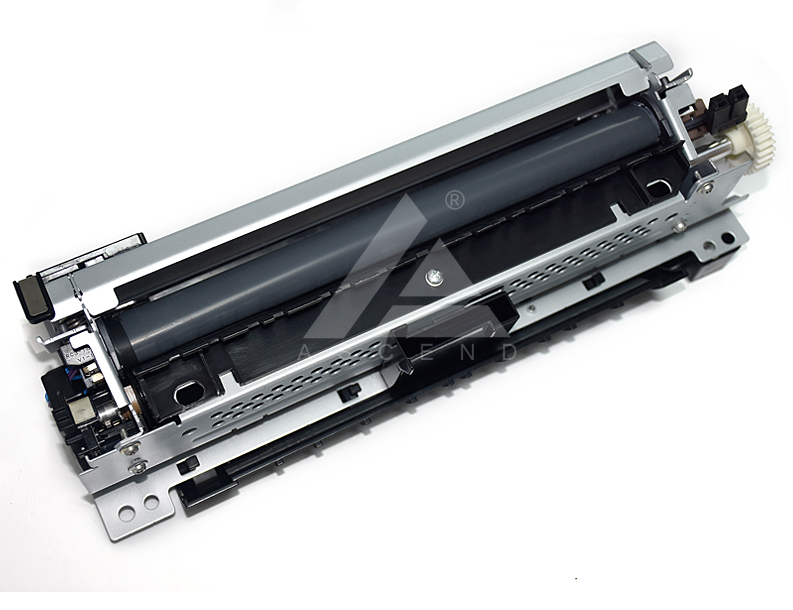

A light source and a few lenses, which shine a bright beam of light on the original document and focus a copy of the image onto a specific place, respectively. A fuser can be considered the ‘final’ main component of a photocopier, as a fuser unit melts and presses the toner image onto the copy paper and imparts the final touches to the duplicate image just before it’s ejected from the machine.

|

Fuser Assembly(Photo Credit : ascendimage.com)

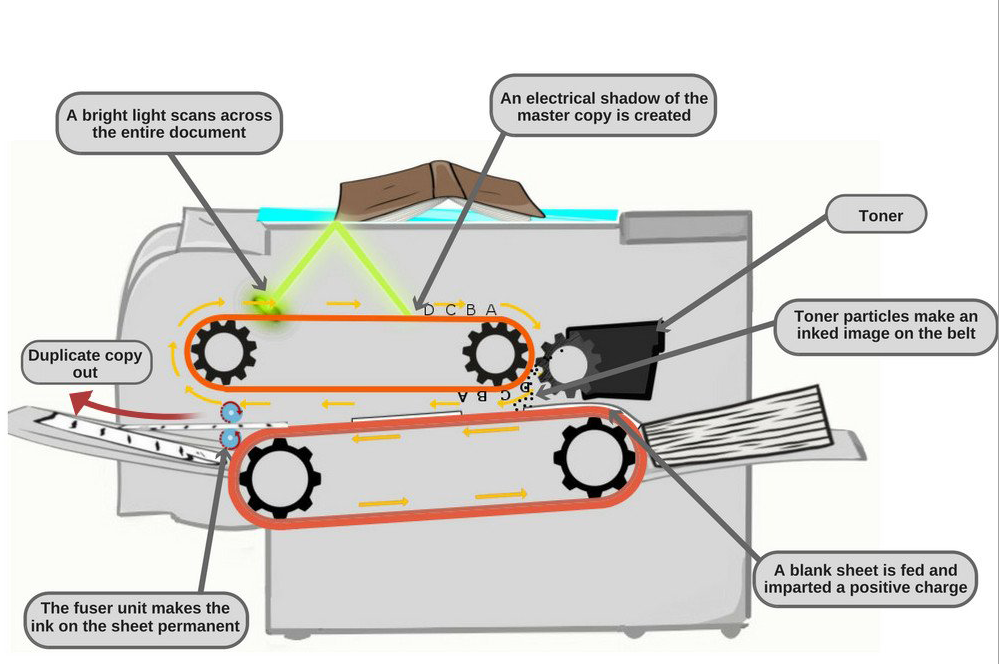

How does a copier work? To begin the photocopying process, the top lid of the photocopier is opened and the master copy is placed face-down on the glass surface, where a bright light beam will scan the entire document. White areas on the paper reflect more light, while black areas reflect little or no light. An electrical shadow (or image) of the master copy is formed on the photoconductor.

|

Copier working principle diagram (Photo Credit : science ABC)

Ascend Technology Co., Ltd. is a leading manufacturer of precision parts for printers, specializing in the design, manufacture and production of copier accessories and laser printer parts. Ascend now handle a wide range of products for most popular models in the market including Transfer Belt,Fuser Film sleeve/Belt, PCR, Lubrication bar, Cleaning web roller, Fuser, Transfer belt Assy, Pick-up Roller/Tire, Upper Fuser Roller, Lower Pressure Roller etc with have got the ROHS certification. |