Currently, there are numerous manufacturing industries in China and the whole world. These industries process raw materials into finished products. The processing may involve chemicals, foods, textiles, machines, and timber. To get the final product, the manufacturing industry employs complex applications. Such applications have many parts that mate. Such parts require gaskets for them to perform correctly. China is among the leading countries, and therefore it makes its gaskets.

What is a gasket?

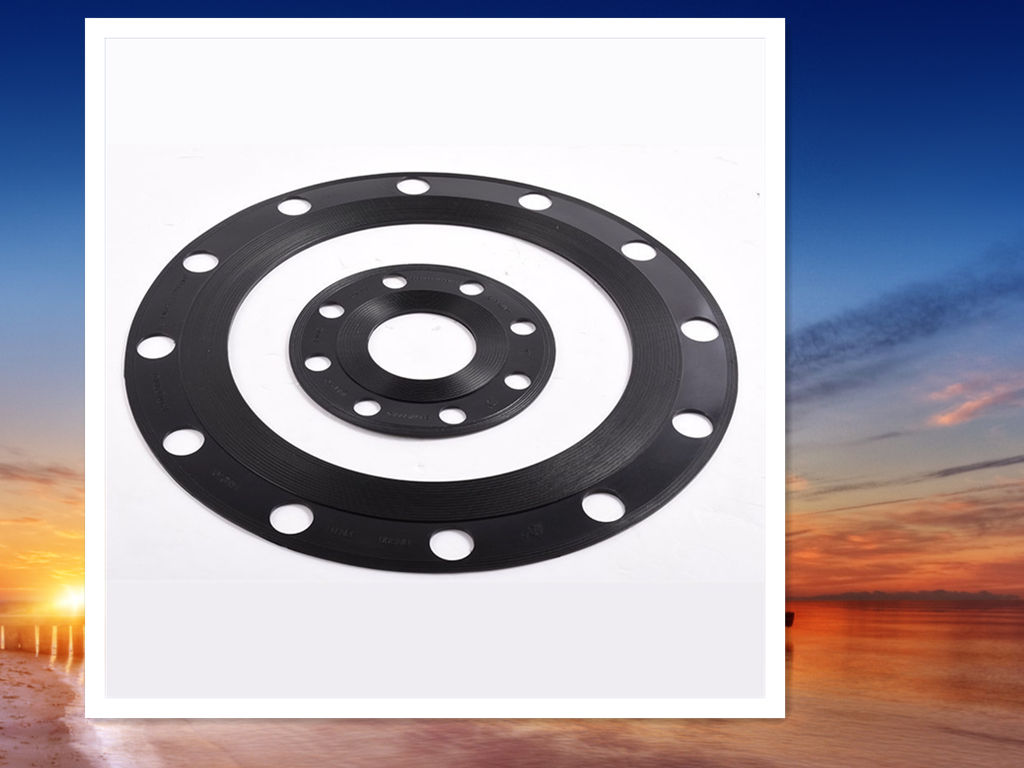

The gasket makes a critical part of any manufacturing industry's system. This part is usually found between 2 or more adjoining surfaces. In actual sense, the gasket acts as a physical barrier. It prevents leakages from fluids, electromagnetic interference, electrostatic discharge as well as potential contaminants such as dirt and dust. Besides, the gasket has excellent potential to reduce extrusion and to creep of parts that are under operating conditions. It, therefore, means that a gasket is essential in filling irregularities allowing for "less-than-perfect" mating between machine part surfaces. Gasket manufacturers in China make Gaskets from thin sheets of metals.

How it functions

A proper functioning gasket is the one that effectively prevents leakages. It means it has sealed away all leaks as a result of being adequately compressed. The compression creates a pressure-tight barrier. This way, it protects the contents within the system. It is common knowledge that moving parts always rub against each other generating friction. Friction is detrimental to the proper functioning of an application. Gaskets protect such parts by separating them.

There are different types of gaskets based on materials. For instance, an elastomeric gasket is effective in protecting against the leakages or inlets of fluids and gases. It creates a perfect seal between the two adjoining surfaces. Such materials are excellent pieces in connecting two parts as well as filling deformities. Owing to the nature of the job of gaskets, they are made from materials that can easily be deformed. Such materials must also have the potential to fill given irregularities adequately.

Common Materials Used To Make Gaskets

Gasket manufacturers in China are conscientious when building gaskets. They select a wide range of high performing materials. These materials possess numerous features for them to be able to function to the maximum. Common materials include;

•Elastomeric materials: these are polymers that have both elasticity and viscosity. They form one of the perfect materials for making gaskets. They include rubber, silicone, polyurethane, neoprene, Ethylene-vinyl acetate, Hypalon and nitrile among others.

•Fibrous materials: these materials include carbon fiber, aramid, cellulose, and glass among others

•Metals: metals that can make gaskets include copper, stainless steel, titanium alloy, carbon steel, and aluminum.

•Softer material: these materials include flexible graphite, cork, as well as PTFE

Industrial Applications

Gaskets are manufactured to provide high performing seals for various parts of the manufacturing process. There are numerous types of industrial application where they can be applied. A top performing seal must provide maximum stability, best fit, and reliability in an application. That means they are manufactured for a specific function. The typical examples of seals include oil seals, rod seals, boiler gaskets, and tadpole gaskets among others.

It is important to note that plastic and rubber gaskets are water cut by the use of water cutting machines. As such they create gaskets with higher tolerance. Besides, all gaskets are easy to fit and long-serving. These critical elements can be used in a wide range of manufacturing industries fitting numerous applications. They find use in industries such as;

•Medical field

•Oil & Gas

•Telecommunication industry

•Aerospace

•Petrochemical and Deep Sea

•Chemical processing

•Power generation

•Mining

•Military

•Aerospace

It is important to note that gaskets come in various specifications, and the choice of material of a gasket for a particular application is chosen based on its features fitting the application. For example,

•Resistance to chemicals for chemical processing industries

•Resistance to temperature fluctuations in sectors that generate higher heat

Gaskets make part of components that are found in planes, cars, boats, pumps, etc.

Examples

•Manway Gaskets: These types of gaskets come in numerous designs. They form the best pieces for closed vessels. You'll find them in boilers and fuel tanks

•Transformer gaskets: transformers are either water or oil cooled. Gaskets are used to seal against the leakage of these water or oils

.

Conclusion

The manufacture of gaskets occurs worldwide, as it is their use. Gasket manufacturers in China offer a vast range of high performing gaskets that they can use in their country as well as export to other countries. In general, the gaskets are built to offer the required resistance to ensure no leakage occurs.