While in the business of producing CNC milling, the material cost can be one of the biggest expenses, directly affecting profitability. But it is possible to reduce material costs without compromising end product quality and changing customer expectations and dependencies. Like most effective commercial cost reduction measures, reducing commodity costs begins with a comprehensive analysis of the various direct and auxiliary ways in which cash flows from the underlying materials are consumed. Here lists some of the ways Bofeng Rapid Prototype Technology Co., Ltd. does to reduce materials cost, to bring benefits to both customers and ourselves: use the lower-cost alternatives if possible, reduce waste, eliminate unnecessary product features, etc.

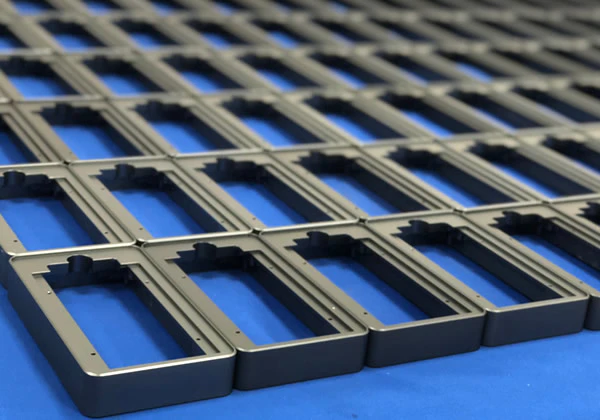

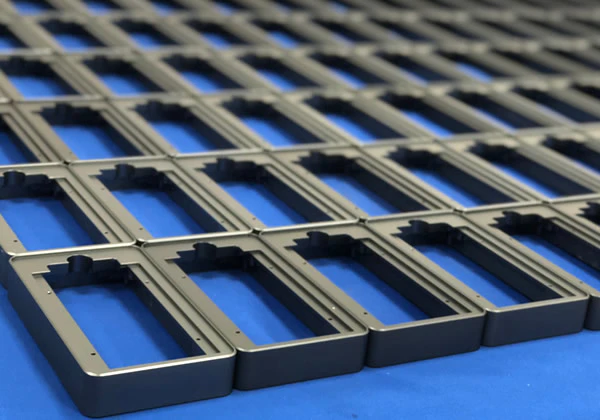

The fame of Bofeng has been spreading in the world. The CNC milling series has become a hot product of Bofeng Rapid Prototype. Bofeng CNC milling is manufactured with superior parts. The steel, carefully selected and processed, is up to the food sanitary requirements, and its quality is guaranteed by third-party inspection authorities. It features water repellency. The coating on its fabric will result in water running off rather than being absorbed into the fabric.

We are moving towards a sustainable future. We establish collaboration with our suppliers by reducing waste and increasing resource productivity.