There are two main types of folding paper box, one is tubular shape, another is plate shape. The former is folded adhesive with two openings.The most common is what we called double plugged paper box,covered lid and buckled bottom box. The latter is folded up from a piece of paper, the most common is what we called the plane paper box.

This article is just to expain the design for tongue and dustproof wing of tubular color paper box in detail. According to Printn-pack normal experience summary, for the lock ways of the box closure and opening , there are three kinds of tongue, friction locking notch, cutting seam locking notch and slot locking notch.According to the different tongue insert ways,there are different dustproof wing designs. Discussing in more detail as below.

Lid design for tubular color box

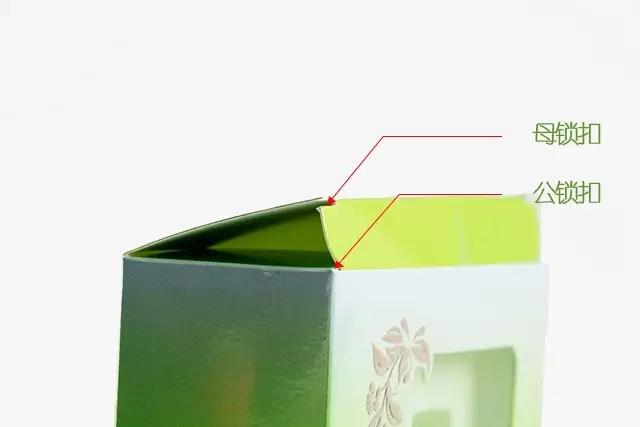

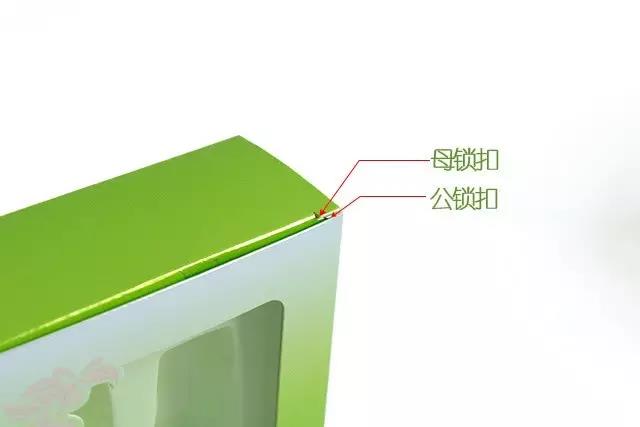

1. Design for insert tongue with friction lock

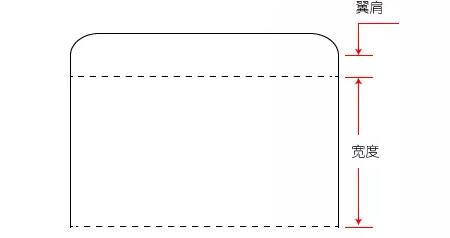

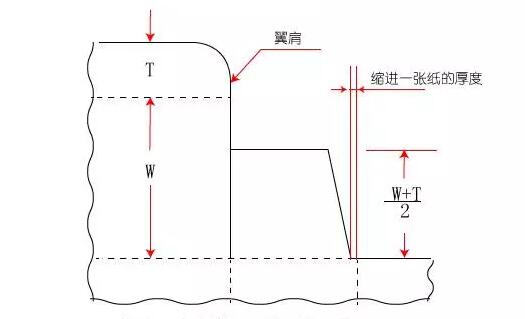

(Picture one) Wing shoulder without indentation

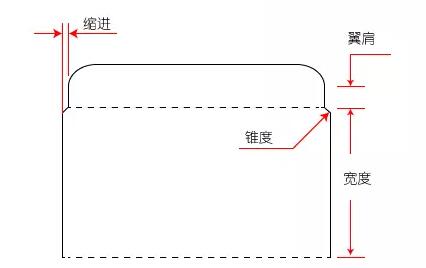

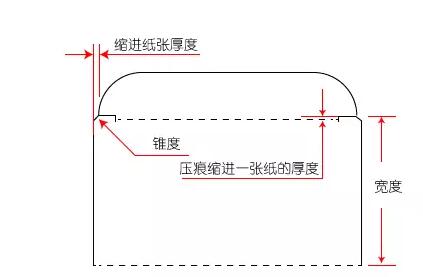

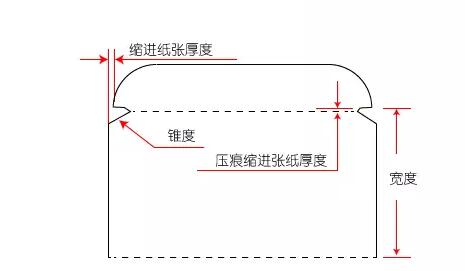

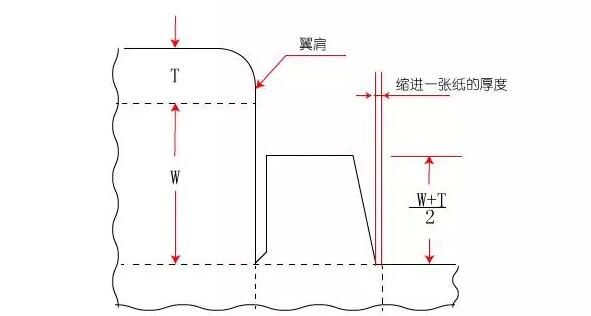

(Picture two) Wing shoulder with indentation, tapered conoer

Friction lock has characteristic that there is “shoulder” between left and right sides of tongue, the rounded coner and the crease , so we call it wing shoulder. The lid is mainly to achieve the purpose of locking by the friction between wing shoulder and both sides of the box body(Picture one). In order to strengthen the friction, sometimes to cut short indentation line on the tongue, using the friction indentation bump and dustproof wing,See below picture.

When the paper is too thick, more than 300g , both sides of the tongue need to indent (Picture2);

When the paper under 300 g and don't need to be indented (Picture 1);

2. Design for insert tongue with cutting seam lock

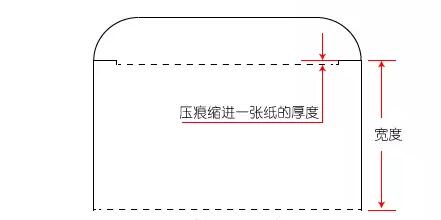

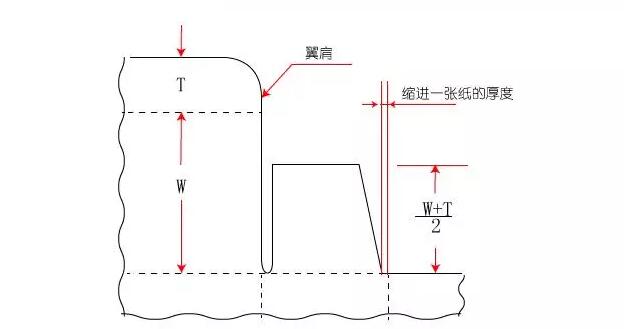

(Picture three) cutting seam without indentation

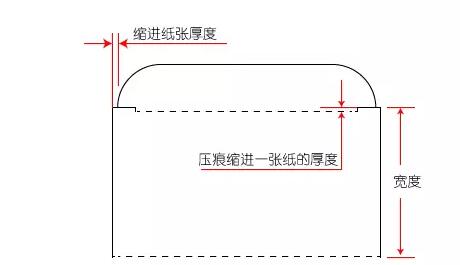

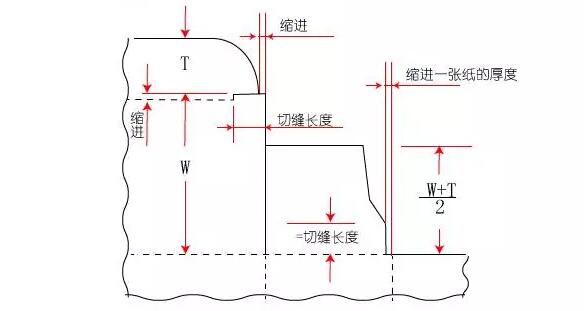

(Picture four) cutting seam with indentation

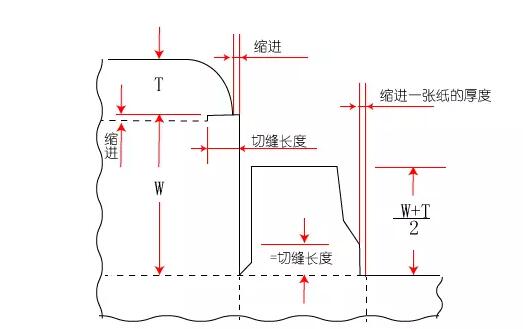

When the customer demands for lid to be closed and sealed highly, we often adopt cutting seam lock. Most of the tubular color box lid is in this structure. Through cutting a crack on both sides of the tongue , after inserting tongue, it will lock together with dustproof wing (below indicated). The lid of this structure is not easy to bounce off, but it is important to pay special attention to the amount of indentation of pressure mark, it is better that the amount of indentation is same as the thickness of a sheet of paper, if shrink too much it is difficlut to lift the lid.

(Picture five) cutting seam with indentation, tapered conoer

When box is large and the paper is thick, the tongue indentation inserted on both sides will be longer. If there is an obvious corner between the lid and the tongue, will be easy to collision deformation in the process of storage, handling, production.So some customer request "bevelment" this angle, so do a inclined taper,Such as (Picture five)

3. Design for insert tongue with slot lock

(Picture six) slot lock with indentation, tapered conoer

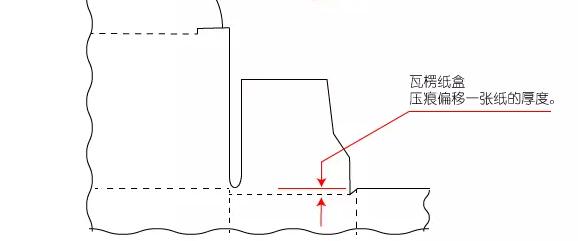

Slot lock (Picture6), is becoming more and more rare, but this kind of structure is very suitable for corrugated color box.

Generally speaking, tongue plugged structure is designed together with dustproof wing, what kind of plugged tongue will have appropriate dustproof wing structure. The dustproof wing of friction lock, only need to design a bevel edge on the side,which work with the plugged tongue,can also have a 6 mm wide shoulder to increase friction. The adjacent side between dustproof wing and lifted lid, it is ok if thin paper card box with single pole (as shown in picture 7), it will requires the slot for thick cardboard and corrugated color box. When slot V-bottom (picture 8)and folde, the line is easy to burst, most of the time, we recommend customers to use the circular slot (as shown in Picture 9).

4. Dustproof wing of friction lock design

(Picture seven) Friction lock, single pole dustproof wing

(Picture eight) Friction lock, V-bottom slot dustproof wing

(Picture night) Friction lock, round bottom slot dustproof wing

5. Dustproof wing of cutting seam design

(Picture ten) cutting seam lock, single pole dustproof wing

The characteristics of the seam lock is that plugged tongue has no shoulder, but dustproof wing has a shoulder, the length of dustproof wing shoulder is tongue cut seam length. There are also different forms of grooving and cutting single pole, Picture 10 is cut single-pole, Picture 11 and Picture 12 is slotted.

(Picture eleven) cutting seam lock, V-bottom slot dustproof wing

(Picture twelve) cutting seam lock, round bottom slot dustproof wing

Need to be aware that when the paper is thick, indentation line of dustproof wing and the lid has certain deviation, the purpose is to prevent the extrusion of dust wing flaps leading to distortion, deformation, even paper burst (as shown in Picture twelve).

Sometimes, friction lock and cutting seam lock can be used together at the same time, the bottom of the double plugged box, can use the cutting seam lock, prevent product dropping;At the top of the lid, open friction lock to lift the lid easily.