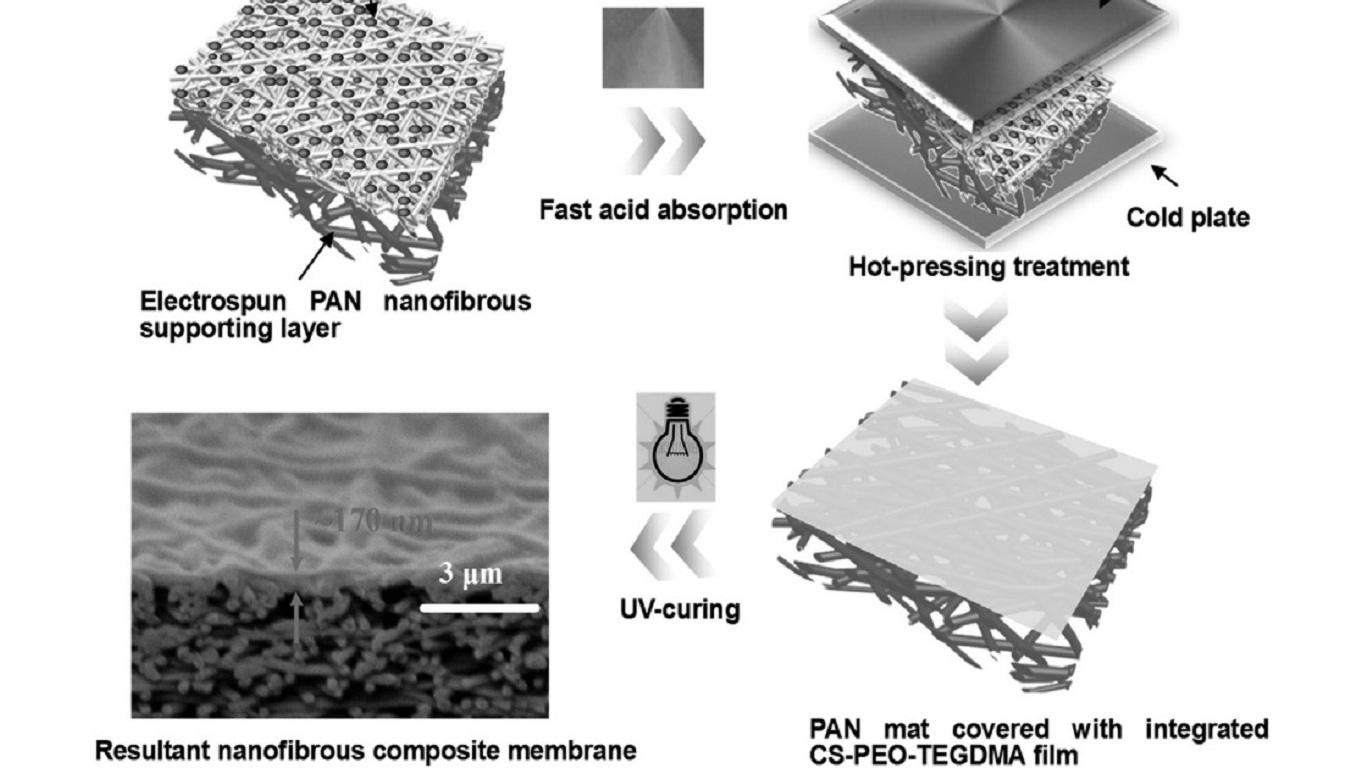

Apart from IP, a combination of electrospraying technique and hot-pressing posttreatment as mentioned earlier was also proposed to fabricate TFNC NF membranes for anionic dye separation. As shown in Fig. 14.13, chitosan-polyethylene oxide-polytriethylene glycol dimethacrylate (CS-PEO-PTEGDMA) hydrophilic nanobeads were the first electrospray on electrospun a PAN nanofibrous substrate and then the top layer was acidic moist-cured followed by hot pressing to form an integrated barrier on the support. Last, an integrated CS-PEO-PTEGDMA layer was formed by UV curing. Notably, the CS polymer chains can be physically crosslinked by the semi-interpenetrating polymer networks among barrier layers without sacrificing the amino (imino) and hydroxyl groups of CS. The optimized TFNC membrane showed excellent NF performance for anionic dye removal with high permeate flux (117.5 L/m2h) and high rejection (99.9%) for Direct Red 80 solution at low feed pressure (0.2 MPa), due to an adsorption-assisted NF process.