Basil seed mucilage (BSM) extracted from basil (Ocimum basilicum L.) seeds that grow in Asia, Africa, and America has been applied to fabricate nanofibers in previous studies. Because of the potential applications of the mucilage for thickening and stabilizing, it is a new source of edible hydrocolloid as a functional ingredient in the food industry. However, BSM cannot be spun alone, and PVA is the most commonly used electrospinning aid agent for BSM electrospinning. Mucilage nanofibers can be utilized as a food additive.

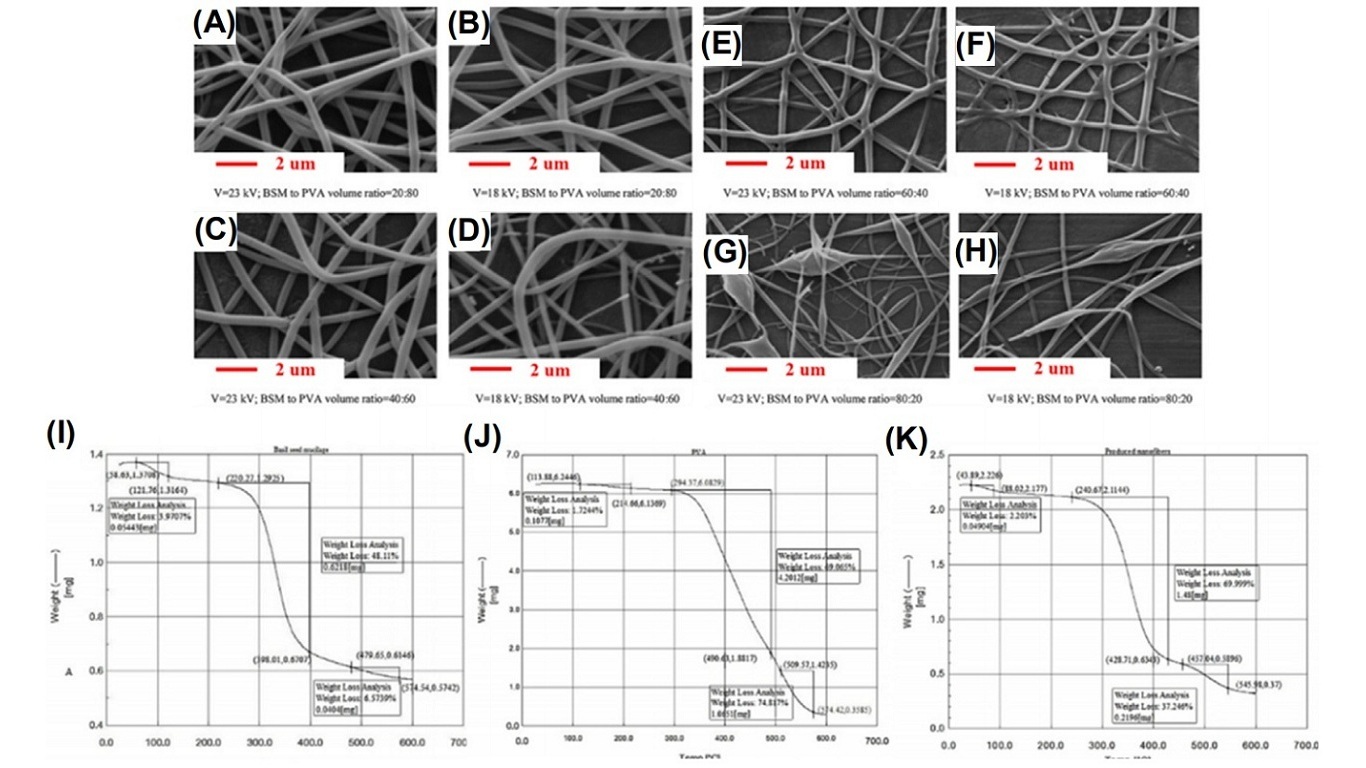

According to the study, water and acetone at the ratio of 7:3 have been used to dissolve 2% BSM. Acetone of good volatility is appropriate for the electrospinning process. A 10% PVA solution is prepared in deionized water. BSM and PVA are mixed at different volume ratios. The results are displayed in the Figure and show that (1) viscosity and electrical conductivity of the biopolymer solutions decrease with increase in PVA content, (2) fiber diameter increases with increase in high voltage and PVA content, and (3) PVA addition improves the thermal properties of the nanofibers. Therefore, thermostable ultrathin fibers fabricated by electrospinning have potential applications in the food sector, such as bioactive encapsulation and edible film production.