Many customers just tell to Printn-pack , "I want a paper box like Iphone packaging!" What kind of paper packaging box they want exactly? the packaging box they want is when pick up the top box, the bottom box will automatically slide within six seconds.

when designing the top and bottom boxes, a lot of printing packaging manufactueres would like to make a semicircular nail under the lid. This design is very ugly, and the manufacturing cost is very high, it is an against humanity design!

Why design the semicircular nail on the lid ? it is convenient to dig out the bottom box, because the lid and bottom box are setted tightly, if there is no nail, the bottom box can't be pull out. If the lid and bottom box is too loose? when Picking up the lid, the body box won't be lifted together, there will be two sepsrate parts. So there is a semicircular nail on the lid.

Now let us learn how to design a lid and bottom box as Iphone packaging box.

What the real beauty of slide design is? The lid and the box body are an organic whole,when lift the lid, the bottom box will automatically slide, not need to design a nail for digging. Sliding speed cannot be too fast, if too fast, it is off guard, the body box will fall to the ground with south of "pa". If so, It was a fall, but not slide.

Size design for paper boxes with lids

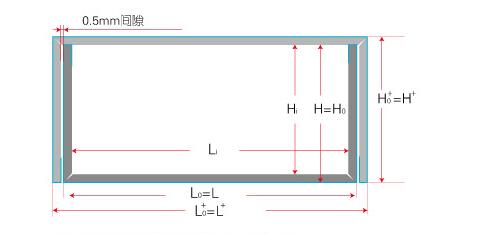

1. Lid and bottom box with V-groove

The structures of side paper box and end face are same as lid and bottom box. Here will use side profile to illustrate.

The characteristics of the box with V groove:

outter paperboard size= maufacturing paper board size=surface paper size

The relationship between paper board size of outter box and inner box:

L+=L+2a+4t+1mm

W+=W++2a+4t+1mm

H+=H+a+t

The grap between outter and inner box is 0.5mm,if the box size is very large, can enlarge the whole box appropriately, but not too be excessive. This gap is to facilitate the discharge air inside the box, or the bottom box is very difficult dig out. If the gap is too large, there is no friction between the lid and the bottom box, will not achieve the result of 6 seconds fall off naturally.

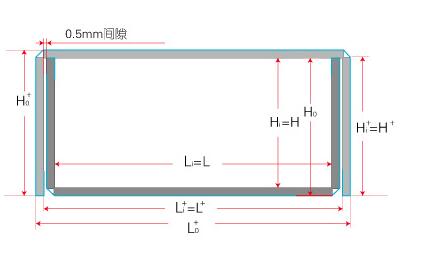

2. Half cutting molding for cardboard boxes with lids

The characteristics of Half cutting molding lid and bottom box:

outter paperboard size= inner paper board size=maufacturing paper board size=surface paper size

The relationship between paper board size of outter box and inner box paper board size:

L+=L+2a+4t+1mm

W+=W++2a+4t+1mm

H+=H+a+t

The grap between outter and inner box is 0.5mm,if the box size is very larger, can enlarge the whole box appropriately, but not too excessive. This gap is to facilitate the discharge air inside the box, or bottom box is very difficult dig out. If the gap is too large, there is no friction between the lid and the bottom box, will not achieve the result of 6 seconds fall off naturally.

Comments:

Manufacturing size (die cutter): Length(L),Width(W),Height(H), outside box use symbol “+”.

Inside size: Length(L1),Width(W1),Height(H1), outside box use symbol “+”.

Outter size: Length(L0),Width(W0),Height(H0),outside box use symbol “+” .

a=paper board thickness, t=surface paper thickness, x= correction factor