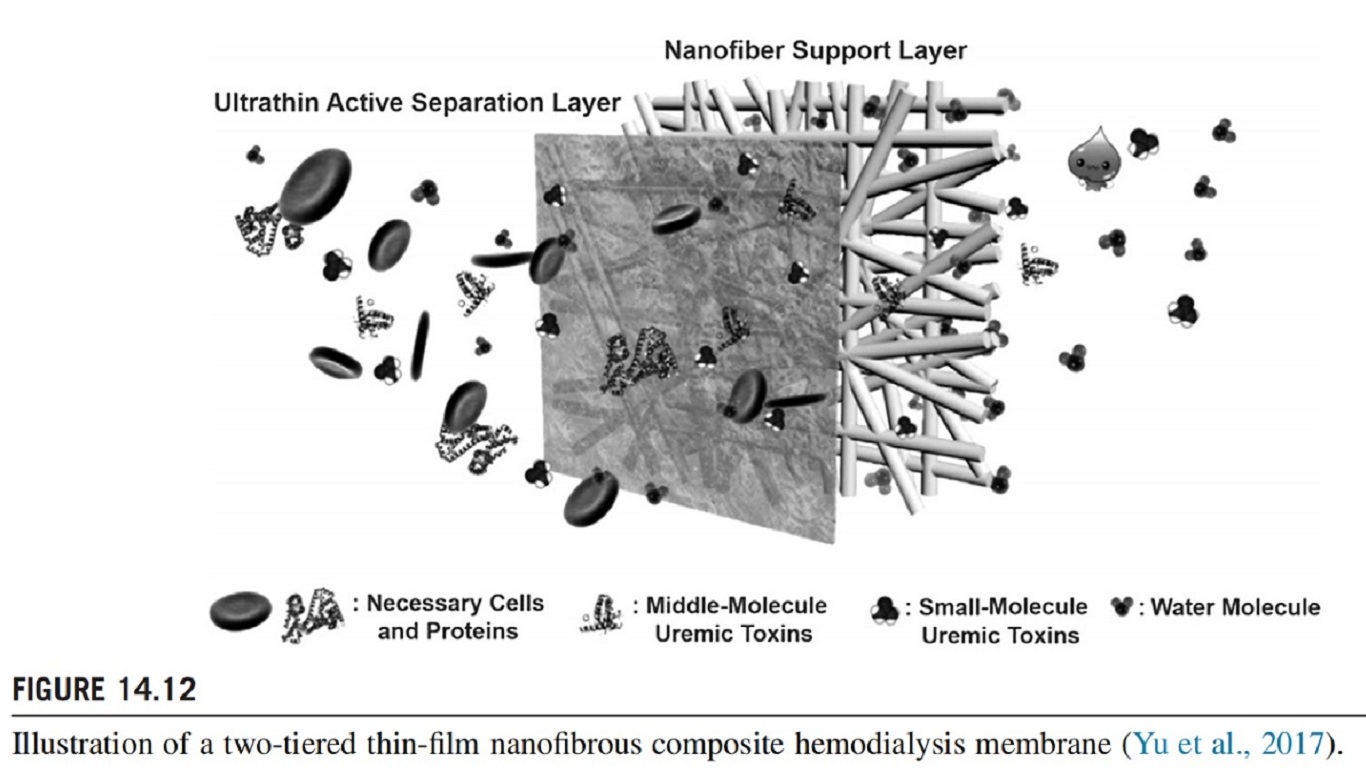

In 2017, Yu et al. attempted a new type of high-performance hemodialysis membrane consisting of an ultrathin hydrophilic active separation layer and a scaffoldlike nanofibrous support layer, as schematically shown in Fig. 14.12. The PVA active separation layer of the two-tiered TFNC membranes could achieve a minimum thickness of the hydrophilic layer, and the open pore structure of the nanofiber support layer favored diffusion and convection. Hence, the uremic toxins, which were dissolved in water, were carried with water and passed through the membrane more easily. This two-tiered TFNC hemodialysis membrane exhibited excellent dialysis performance, especially for the middle-molecule uremic toxin removal. It may break the bottleneck of trade-off (to reconcile the desire for high removal of middle-molecular toxic substances and high retention of big proteins at the same time), which indicates that the two-tiered TFNC membrane has a potentially wide application for hemodialysis. It is imperative to point out that these two-tiered TFNC hemodialysis membranes have not been optimized, and the chosen material system (i.e., PVA for the active separation layer) may not be the most appropriate one for an artificial kidney in practice (e.g., compared with commercially available hemodialysis membranes because of their hollow fiber configuration). Therefore, for the future development of TFNC hemodialysis membranes, other hemodialysis materials and their modification are necessary to achieve better blood compatibility and more efficient dialysis performance.