The EKE superheat controller & Colibri expansion valve are the perfect combination to provide optimal superheat (SH) control for process cooling in the food industry. Good SH control is critical, because it maintains optimum evaporator performance for both energy efficiency and cooling.

One of the main challenges with blast chill or blast freeze in food process applications is the turndown ratio required in the cooling capacity from initial to final load at the target and holding temperature.

Here's a quick example:

To cool a product from 40°C to 2°C with an initial cooling load of 100 kW at 40°C and a holding cooling load of 20kW at 2°C, the refrigeration system would need to have capacity control to maintain the correct functionality from the maximum capacity through to the minimum capacity. One often overlooked area is the performance of the evaporator and control of the expansion valve across the whole duty/process time line.

With a traditional thermostatic expansion valve (TEV), the turndown ratio is about 70% of maximum capacity, which leads to instability if the minimum cooling capacity is below this percentage — as is the case in the above example.

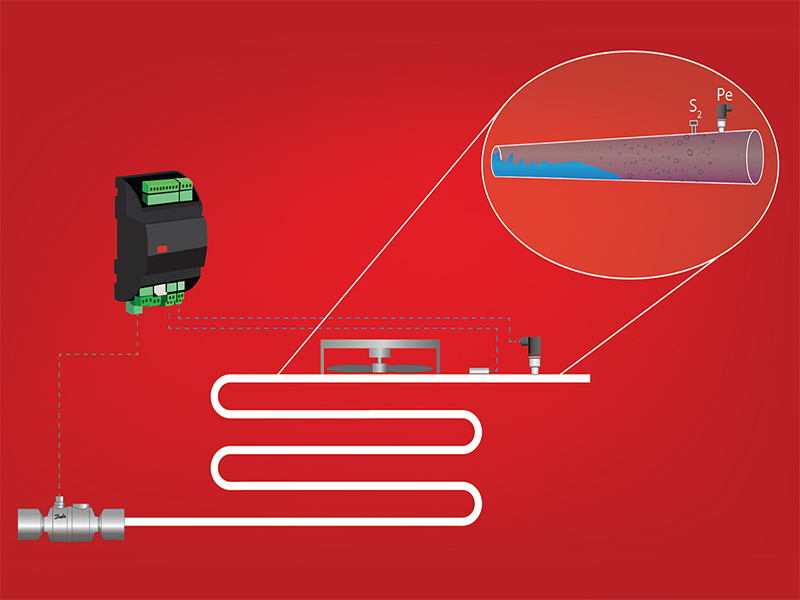

The benefits of combining an EKE and an electric expansion valve (EEV) are three-fold.

The first benefit is the ability to maintain the minimum stable superheat within the evaporator. Here's a quick break down

1.When an evaporator is "under-filled" with refrigerant, the superheat signal is high and very stable at the outlet of the evaporator. Only a small area of the evaporator is utilized, resulting in degraded performance.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you’re interesting in heat pump products,please feel free to contact OSB heat pump. We are your best choice.