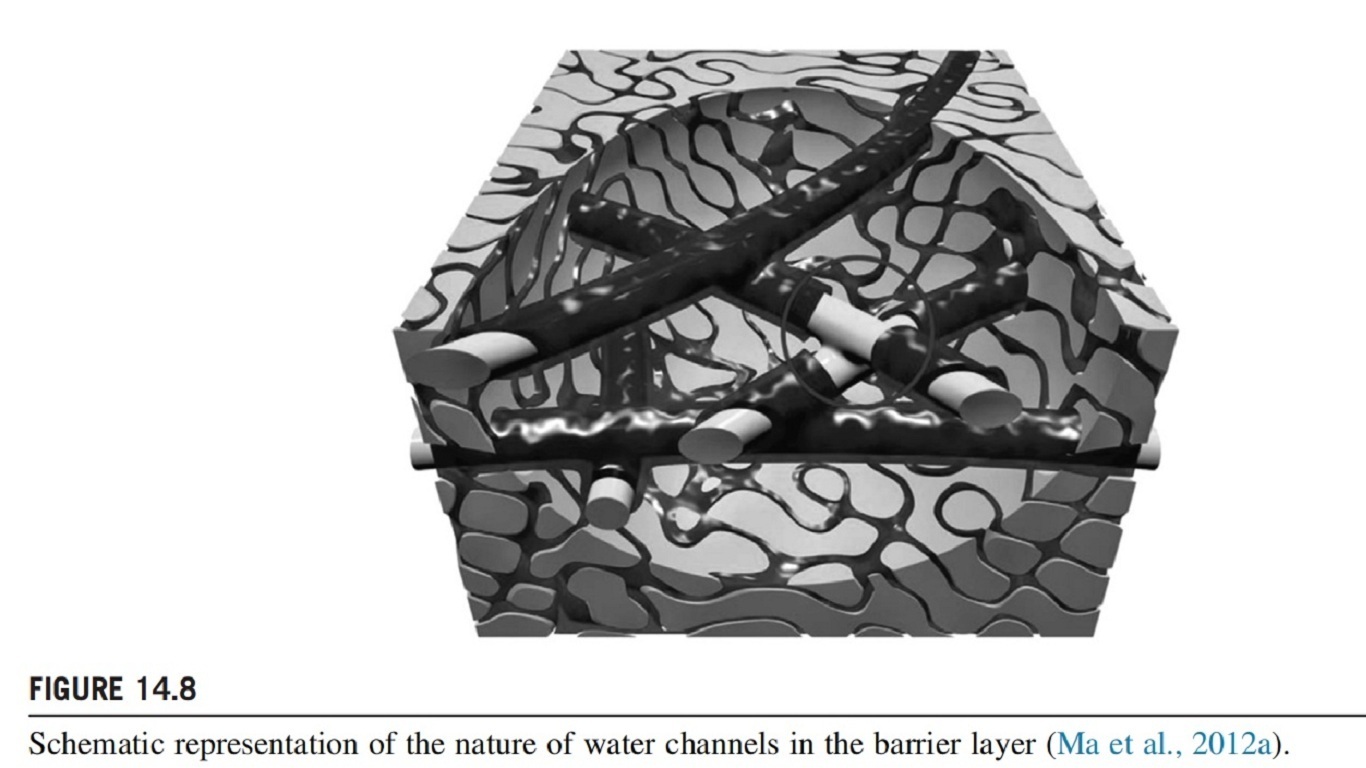

It should be noted that based on the concept of TFNC membranes, several breakthroughs in UF performance were made as a result of the following factors: (1) The nanofibers in the midlayer support have unique properties. The typical porosity of an electrospun scaffold is above 80% (it is about three to four times higher than that of conventional membranes prepared by the phase-inversion method). And the pores in an electrospun scaffold, as defined by stacking of nanofibers, are interconnected. (2) Directed water channels created through the interface between the nanofiber and the polymer matrix in the barrier layer are implemented in the filtration (as schematically shown in Fig. 14.8). In other words, part of the electrospun scaffold has been incorporated into the barrier matrix. The key feature of this structure is that as the embedded nanofibers are interconnected, the interface between the nanofiber and the barrier matrix can be used to generate water channels for more efficient water transportation. These directed water channels could be of great benefit in increasing the water permeate flux. (3) The barrier layer has a unique ultrathin structure. The thickness of the barrier layer in this structure is typically on the order of 50-500 nm, depending on the fabrication process, through coating, electrospinning combined with solvent vapor exposure, electrospraying combined with solution treatment, electrospraying combined with hot-pressing treatment, or other means. (4) Hydrophilic materials are used as the barrier layer, including crosslinked PVA, crosslinked polyethylene glycol, CA, chitosan, chitin, and polysaccharide ultrafine nanofibers. The increase in hydrophilicity of the barrier layer was found to enhance the anti-fouling properties of UF membranes. It is interesting to note that most of the commercial membranes are made of hydrophobic materials, such as PVDF, etc., because these polymers are durable under long-term operation in aqueous solutions. However, the hydrophobic surface has a lower surface energy, which would lead to the adsorption of lower-surface-energy materials and thereby result in fouling and reduce the water permeability during the UF process. Thus, a hydrophilic membrane surface would be of benefit to maintain a high permeate flux.