Everyone knows! At present, the melt-blown cloth and mask industries have entered a critical period of industrial adjustment and technological upgrading, and high quality is the mainstream of the market.

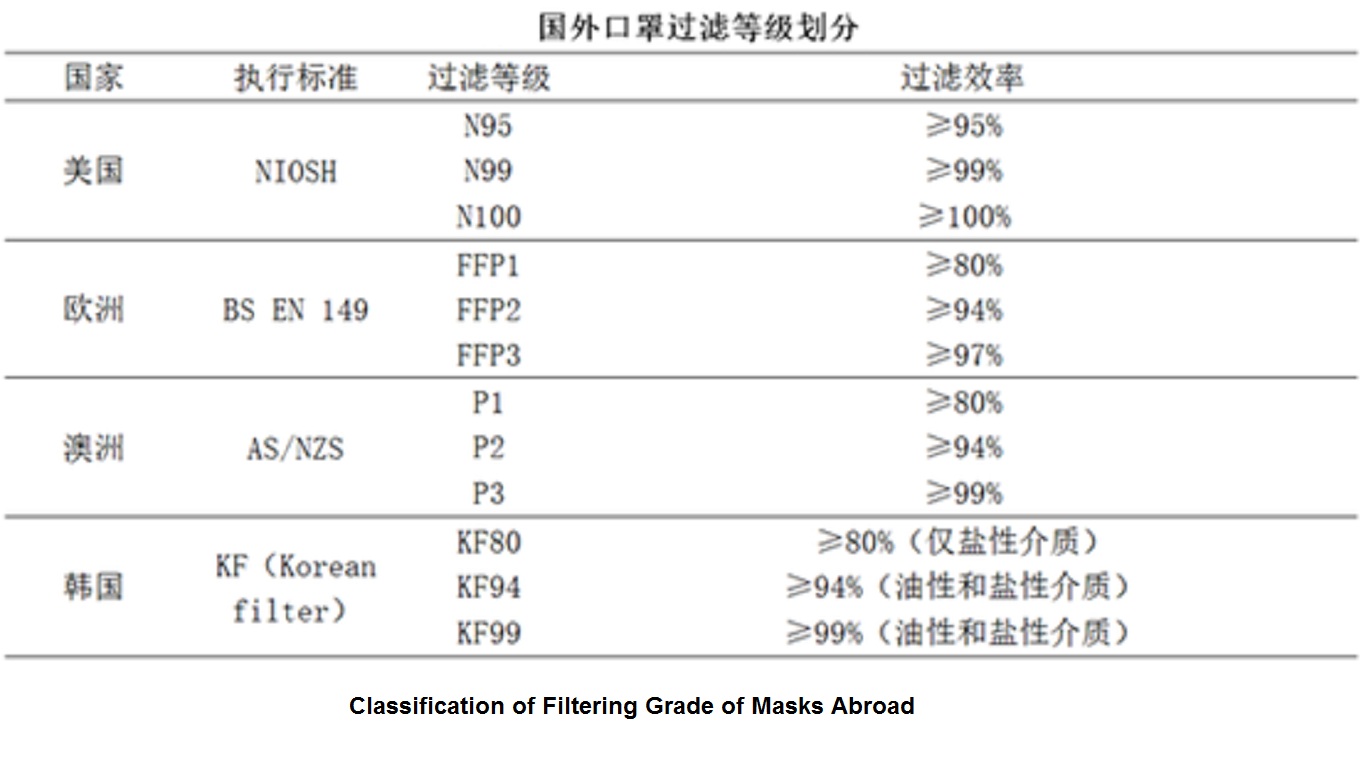

Public information shows that melt-blown material has 25g and 50g, filtration efficiency has 92%, 95%, and 99% and other several grades, is usually referred to like 90%, 95%, and 99%, respectively on behalf of 90%, 95% and 99% of non-oily particles. Current EU standards require melt-blown at 95L/min flow conditions under the test, the filtration efficiency of more than 94%. From this point of view, less than 90% of the melt-blown fabric has not met the export standards of masks demand.

So, how to save the low filtration efficiency melt-blown fabric?

-- Qingzi Nano "nanofiber melt-blown machine", through more than 50% of the melt-blown cloth processing, the final filtering effect (PFE) can reach 95~99%!

-- When the melt-blown cloth of less than 90% is processed by the equipment to reach level 95 and 99, the profit can be increased by many times!

◆ Technical Advantages

Pure physical interception, no static decay, stable filtering effect.

◆ Equipment Introduction

Final filtration efficiency (PFE) after processing: 95~99%;

Delivery date: 10-15 days;

Width: 300mm, 660mm;

Production speed: 12~30m/min;

For further information, please send an e-mail: winnie@qingzitech.com