I. complete range of bending mould

There are L-type, R-type, U-type and Z-type bending dies. The upper die has different angles such as 90 °, 88 °, 45 °, 30 °, 20 °, 15 °. The lower die has 4 ~ 18V double and single grooves with different groove width, and R lower die, acute angle lower die, flattening die, etc. The upper formwork section is generally 300 mm, 200 mm, 100 mm, 100 mm, 50 mm, 40 mm, 20 mm, 15 mm, 10 mm, and the whole section is 835 mm. The lower formwork is generally divided into 400 mm, 200 mm, 100 mm, 50 mm, 40 mm, 20 mm, 15 mm and 10 mm, and the overall formwork is 835 mm.

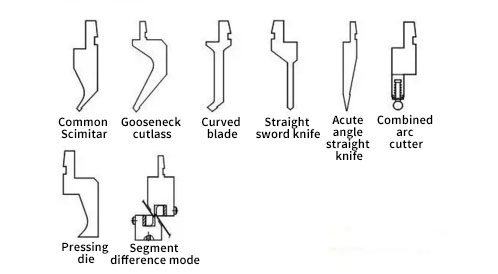

1. The common types of bending upper die (bending tool) are r = 0.2, r = 0.6, and the tool angles are 88 ° and 90 °.

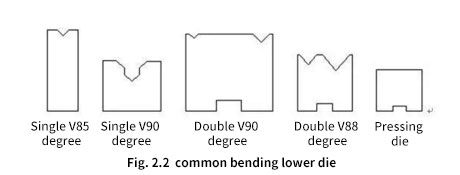

2. The commonly used V-grooves for bending the lower die (V-groove) are: V4, V5, V6, V7, V8, V10, V12, V16, v25 (the number represents the width of V-groove). The commonly used V-groove angles are 88 ° and 90 °.

II. Composition of bending die

General mold is divided into intermediate plate, upper mold, lower mold, guide rail, lower mold base, this kind of mold has strong universality, most of the processing can be completed.

III. selection of bending die

To process different parts, we need to use different molds. We need to know the machining parameters of machine tools and molds, and then we can choose the matching molds.

1. Select the applicable mold according to the shape, size of the workpiece after forming and the inner R angle marked on the process drawing;

2. Give full consideration to the possible abnormalities in the forming process, such as: colliding with pig's beak and rivets, colliding with die and machine, and colliding with each other in the folding edge of workpiece, etc.

3. Selection of V groove when bending workpiece

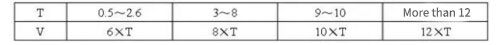

According to the different thickness of materials, the selection of V groove is also different (t is the thickness of sheet metal)

When t ≤ 4mm, V-slot = t * 6 times; when t ≥ 4mm, V-slot = t * 8 times

4. Note: when bending at 90 °, the width of V groove shall not be less than 4T, otherwise the mold may be damaged or the workpiece may be scrapped;

5. If the size of the hem is too small and the V-groove below 4T must be used, a suitable obtuse angle can be folded first, and then the large V-groove can be folded for 90 °;

6. Thoroughly clean the tool mould and machine tool mould base to ensure that there is no dust or hard object;

7. Take out the center of the machine tool with the upper and lower die with a length of no less than 300mm, and pay attention to the appropriate pressure to avoid damaging the die;

8. Replace the appropriate mold required for this processing, clamp the upper and lower parts in place, and lock the fastening screw clamp plate;

9. The mould shall be clamped in the center of the machine tool as much as possible to ensure the continuous and stable operation of the machine tool.

Machine parameters include: stroke, processing capacity, opening height, type of intermediate plate, etc.; die parameters include: type of upper die handle (matching with intermediate plate), pressure tonnage (bending pressure), etc.

Therefore, we need to choose from "machine parameter" and "die parameter".

On the choice of machine parameters

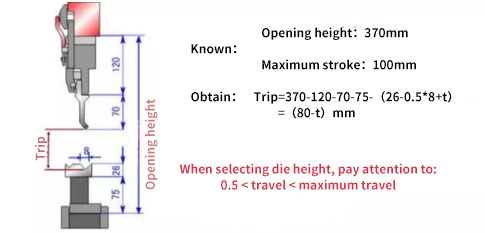

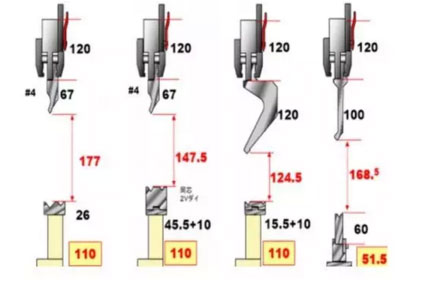

1. Selection of mold height

Stroke (mm): opening height - middle plate height - upper mold height - lower mold seat height - (lower mold height - 0.5V + T) t is plate thickness (mm)

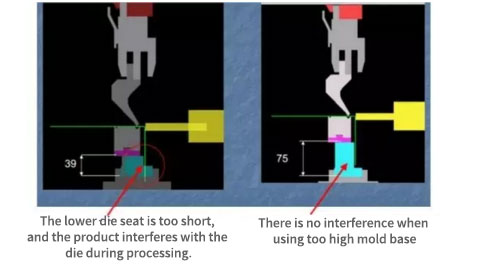

When selecting the lower die holder, we should also pay attention to that the lower die holder has a variety of heights, and the die holders of different heights are used for different processing.

Different mold combination height can be obtained by using different mold combination to process different parts.

On the selection of die parameters

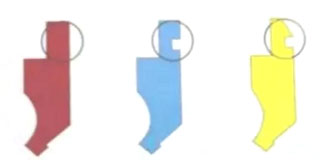

1. Form of upper mold handle

There are three types of die handles for upper die to fit different intermediate plates

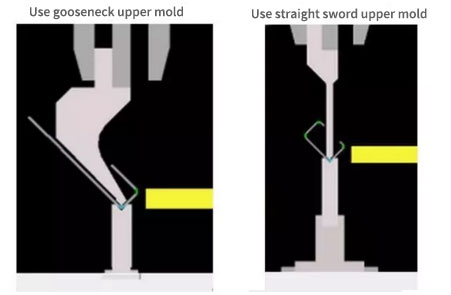

2. Upper mold shape

The common standard shape upper die is:

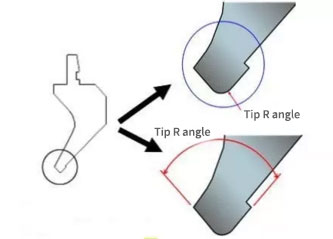

3. The R angle of the upper die tip and the R angle of the upper die tip are:

(1)0.2R (2)0.6R (3)0.8R (4)1.5R (5)3.0R

Select appropriate tip R: generally use r0.6 below 3mm

The tip angles of the standard upper die are 90 °, 88 °, 86 °, 60 °, 45 °, 30 °, etc.

The included angle of the die is smaller than the processing angle. For example, we bend the workpiece to 90 ° and use the 88 ° included angle die.

4. Form of lower mold

Generally, the lower die has the difference between single V and double v. in these two types, there are also the division and the whole section. Different die types are suitable for different processing needs.

Generally speaking, the single V mold is more widely used than the double V mold, and the split mold is more widely used than the whole mold. Our use of lower die is generally double V and three v.

5. V width of lower die and V groove angle

The relationship between the selection of the lower die V groove and the material thickness (T):

The included angle of the V groove of the lower die is the same as that of the upper die.