The 2019 will be new progress year of Chinese intelligent machines. After a few years of precipitation and accumulation,industrial machine development will usher in a great wave. We know, Industrial robots is with their years, and do replace some of the human work.

HMI PLC all in one, different size display screen, higher resolution, intuitive graphical interface operation, easy to understand, and much improved efficiency, which not only reduces costs, but also increases output yield.

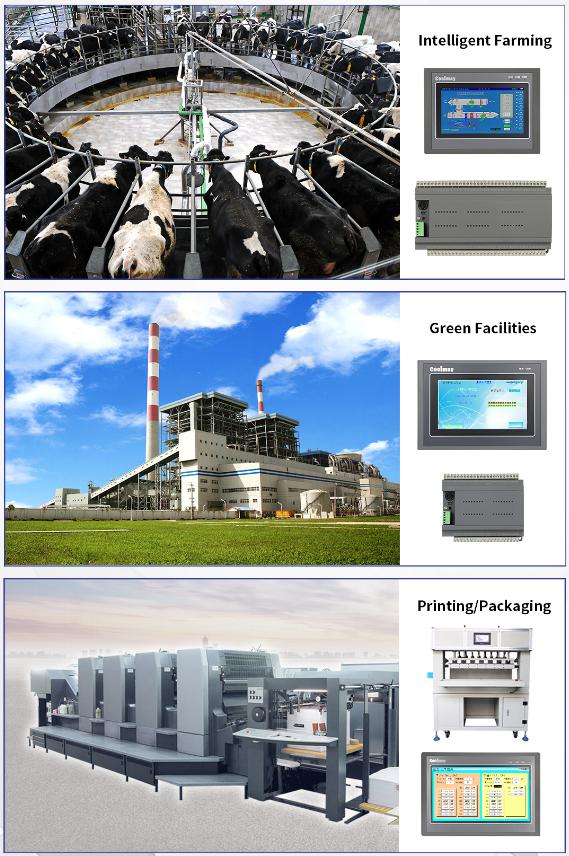

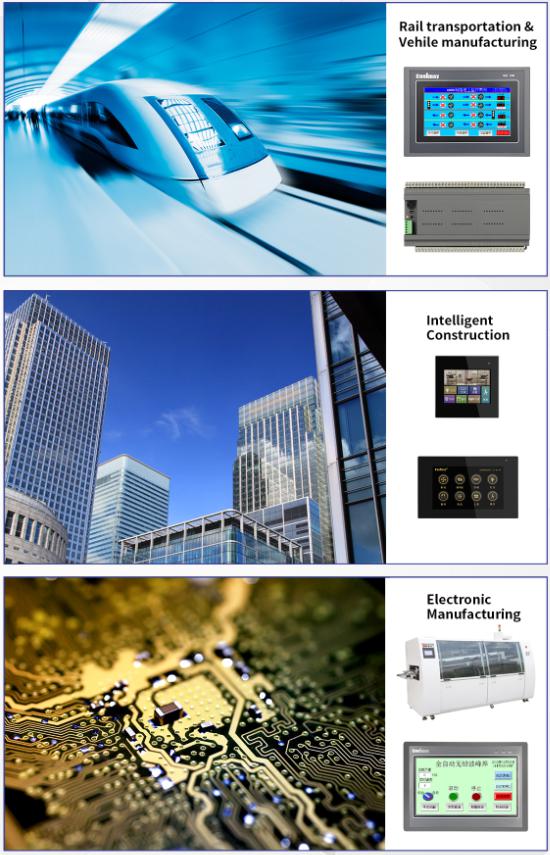

Applications: Environmental engineering, agriculture, forestry and animal husbandry (aquaculture), intelligent construction, rail transportation, vehicle manufacturing, electronic manufacturing equipment, textile machinery, packaging machinery, printing and packaging, engineering machinery, HVAC machinery, plastic machinery, food machinery, AGV trolleys, air compressors, rubber and plastics machinery, etc.

Agriculture, forestry and animal husbandry

At present, the development of rural labor transfer and rural urbanization,the essential problem that China and world’s future agriculture are facing is “who will feed pigs? “who will raise chickens?”and “who will plant land?”

From the perspective of international development trends, modern agricultural production relies mainly on machine and equipment, and cannot rely on only human beings labor. “How many times do you feed”? “How much each time?” “What material to feed?” In the past,all these relied on staffs’ experience. While In the future, it will depend more on intelligent equipment. As long as the equipment is working properly,each process run as its setting, the pigs will be fed well.

The final trend is “human operate the machine to control each working process”, we are entering intelligent age.

We have customers who use our hmi/plc all in one in the Fungus breeding and egg incubating, temperature and humidity etc could be controlled in very high accuracy, the whole process is controlled by plc and could be monitored on HMI, Supporting remote operating and you could get alarm sound/message if any trouble to avoid wrong operation.

Video Link reference: https://www.youtube.com/watch?v=pVPEdORLk4U

Warehouse transportation management

Taking example by Uniqlo, all clothes checking and sorting work in the warehouse is made by robot, they reduce 90% human labors and could work 24hours continuously.

1. Adopting PLC's PID algorithm (supports self-tuning), flexible frequency control, which is suitable for different places

2. Automated energy management to maximize the matching of practical power and reduce power waste.

3. Program economy, greatly reducing costs.

Case demo for reference: http://gv47cd6f.allweyes.com/tunnel-traffic-comprehensive-control

Intelligent Building

Through intelligent control technology, intelligent sensing, intelligent management, artificial intelligence and other technologies, Coolmay smart products have been successfully applied in rail transit, intelligent buildings, smart factories and so on.

Using highly integrated PLC/HMI all in one, all operations are easily completed by clicking the HMI touch screen, great saving raw materials and energy.

Rail transporting with plc controlling, and dynamic weighing etc are not imagination, we could take it true.

Smart panel is widely used to easy our life, throw away those complex switches, HMI could integrate all switch on/off by one, realizing its remote controlling.

House controlling :https://www.youtube.com/watch?v=-9J-1WrYFzw&t=166s

https://www.youtube.com/watch?v=-FxJsqAcII0&t=31s

Some experts predict that robots will replace 77% human labors in 2045, but we believe that machine substitution is not to let the machine completely replace people, but to achieve the perfect synergy and coexistence between machines and people. Intelligent industrial products is becoming the core driving force of the next industry, and are more likely to become the beginning of a new discovery, big change, great integration and development of human society, even partial substitution of human labor, and fundamental changes in lifestyle.