The development of mechanical watches has gone through hundreds of years of history. Up to now, the structure of mechanical watches is very precise. Let me introduce the internal structure of the automatic mechanical watch today!

1. Classification

Mechanical watches can usually be divided into the following two types: Manual winding and Automatic winding watch (AUTOMATIC). The power source of these two mechanical watches is powered by the spring in the movement, which drives the gears and pushes the hands. Just the way of power source is different. The mechanical watch that is wound on the hand is powered by hand. The thickness of the movement is thinner than that of the automatic spring winding watches. The weight of the watch is relatively lighter. The automatic winding watch uses the movement of the automatic rotating disc of the movement to generate power to drive the spring, but the thickness of the watch is relatively larger than that of the clockwork.

2. Structure

Watch Gear

The gear train of the watch, especially the main drive train, widely uses a circular tooth profile. This tooth shape is derived from the connection of the tooth profile. Since the pure cycloidal tooth profile is difficult to process, the arc is used instead of the cycloidal wire, also called the modified cycloidal tooth profile, which enables the minimum number of teeth of the pinion to be 6, Therefore, a large transmission ratio can be obtained under the condition that the number of teeth of the wheel is not too large, which is extremely advantageous for reducing the diameter of the movement and for the high-frequency watch. The transmission efficiency is relatively high, generally reaching about 95%. Due to the small size of the movement of the watch, the energy stored in the barrel wheel assembly is not large. If the energy loss is too large, it will directly affect the travel time quality of the watch and is more sensitive to machining errors. For example, the tooth profile error and the center distance error cause a change in the meshing characteristics. Since the tooth profile is determined by the pair of gears and the modulus that are meshed, the number of teeth and the modulus are different, and the usage of hob and cutter are also different.

Escapement Mechanism

The composition is very simple, the Swiss watch parts are relatively small, mainly built up by escapement wheel, pallet fork parts (including pallet fork, inlet tile, outlet tile, forged nail, and fork shaft), double disc parts (double disc, disc nail) and limit on main plate Bit nails and other components. However, some watches do not use limit nails, but directly cut the two bosses on the main plate or the fork plate to limit the position. There is also a nail that protrudes from the pallet member and is inserted into a hole in the main plate to be constrained by both walls of the hole. The escapement mechanism is called fork-type cymbal mechanism, which is further divided into a straight fork type and a side fork type. The former is an escape wheel shaft hole, a pallet fork shaft hole, and a pendulum shaft hole on a line; while the latter is a certain angle between the three holes. Although the two forms are different, their composition and working principle are the same.

Balance Spring

The balance spring is the part that produces a stable vibration frequency. These two parts are organically linked by the transmission wheel train and the escapement mechanism, forming the backbone of the watch movement. The vibration of the balance spring assembly consumes a certain amount of energy, and this energy supplement is supplied by the prime mover. The supply is strong, and the balance spring assembly has a large swing; on the contrary, the supply energy is weak, and the balance of the balance spring assembly is small, that is, the swing is small. If the supplied energy is always kept constant, the swing angle of the balance spring assembly is also unchanged, that is, the swing amplitude is unchanged. It is impossible to supply energy invariably, because the mechanical watch has a tight spring to supply the motive force. As the spring is relaxed, the torque will become smaller and smaller. Of course, the energy supplied will also become weaker. In addition, this energy is passed through the drive train and the escapement mechanism, and the meshing characteristics of the drive train gear transmission, the operating characteristics of the escapement mechanism, the transmission efficiency, the efficiency of the escapement mechanism, etc. are constantly changing, so the internal swing of the bar wheel spring assembly is also different at different times. If use the swinger or the swing recorder, the values shown are constantly fluctuating. Generally, the average value of the maximum value and the minimum value during a certain period of time indicates the swing during that period.

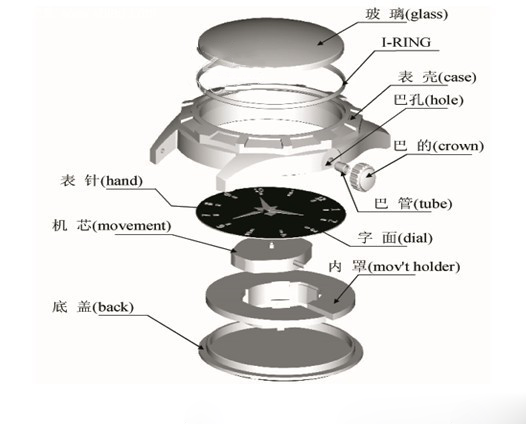

A Part of Super Time Automatic Mechanical Watches: