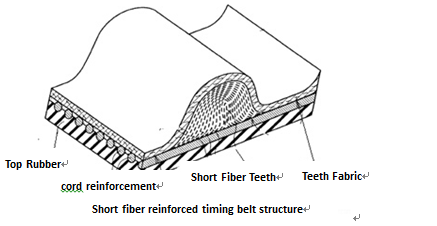

1 Short fiber reinforce timing belt

The requirements of modern automobile for timing belt are: service life of 250000-300000km; service temperature of - 35-150 ℃, instantaneous high temperature of 175 ℃; oil resistance of ≥ Cr; service life of stand at 150 ℃ of 3000h, without sacrificing its low temperature performance when improving oil resistance, dynamic storage modulus of belt teeth ≥ 1.4mpa.

To achieve such a high condition, only HNBR / zinc methacrylate (ZMA) composite cured by aramid short fiber reinforced composite are used.

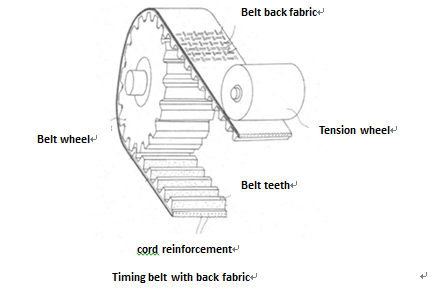

2 Timing belt with back fabric

Due to the limitation of manufacturing technology, the back of the timing belt is usually pure rubber. Now, the back of the timing belt needs to drive other components such as oil pump and tension mechanism, especially the direct injection diesel engine. It is required to have a large tension, so the back wear is very large, pure rubber cannot meet the requirements. If the back of the belt is made of fabric,the wear resistance of the back of the belt can be greatly improved.

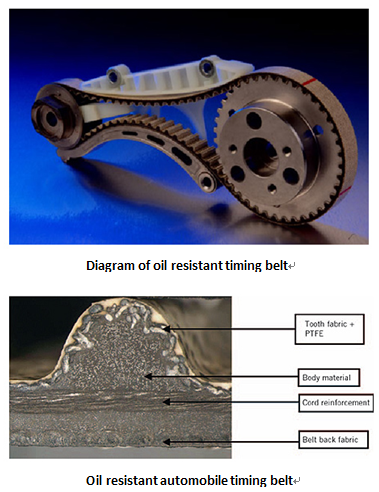

3 Oil resistant timing belt

It can make the timing belt directly contact with the lubricating oil like the chain, omit the tensioning wheel and use the guide rail for tensioning and guiding, so that the friction coefficient of the belt can be reduced by 30%, and the structure space can be more compact.

Oil resistant timing belt is a great breakthrough in drive belt technology, which changes the traditional concept that the drive belt cannot contact with mineral oil. The belt formula needs HNBR with high acrylonitrile content, the coating compound of fabric needs to contain a large amount of Teflon (PTFE), and the cord reinforcement needsto use high-strength composite glass fiber or carbon fiber.

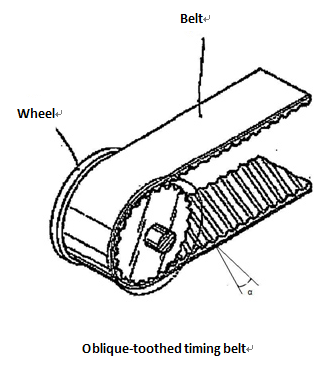

4 Double Helical timing belt

The double Helical timing belt t is similar to herringbone gear, the biggest advantage is to reduce noise, transmission capacity and service life are also greatly improved. Compared with the same toothed straight tooth timing belt, the noise of the belt can be reduced by 10-26db, the service life can be increased by 120%, and the transmission capacity can be greatly improved (or the bandwidth can be reduced).

5 Oblique-toothed timing belt

The principle of Oblique-toothed timing belt is similar to helical gear, and its helix angle α ≤ 10 °.