Feature:

Usage: apply to aluminum profile, pvc, common light alloy profile, can be used for drilling, milling all kinds of holes.

1 With euro style design, creative technology, simple, clean.

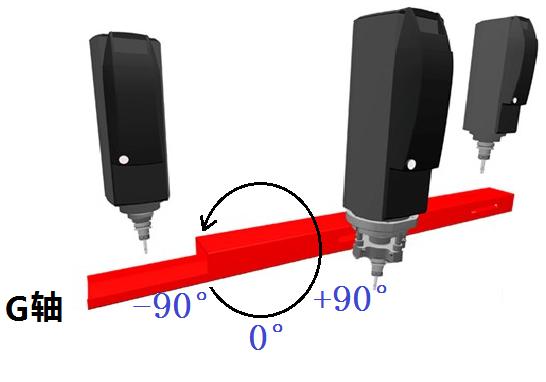

2 Worktable can rotate (-90)~0~(+90) angle, after one time clamp can process three side

3 Adopt (Taiwan LNC) CNC system, friendly human-computer interface, stable system, high precision, easy operation.

4 Adopts high quality HXL high speed spindle 18000rpm/5.5KW.

5 Adopts Japan Yaskawa servo motor, Hinwin linear guide, linear slide guide and imported bearing.

6 With 6-position rotated tool change system, can automatic change blade fast.

7 With cooling system, can cool down blades.

8 Closed visiable protective cover, with working light, make sure can observe when processing and the safety of operator.

9 With aluminum chips collect function, make sure the cleaness of worksite.

G-axis processing diagram(图2)

2、Main technical parameter

Item | Unite | Testing data | |

Processing size | X | mm | 3500 |

Y | mm | 200 | |

Z | mm | 230 | |

Worktable rotate angle | G axis | ° | -90°~ 0°~ +90° |

Processing precision | position | mm | ±0.1 |

reposition | mm | ±0.05 | |

Drilling sag | mm/mm | 0.1/100 | |

cylindrical | mm | 0.1 | |

Cutting surface roughness | um | Ra 12.5 um | |

Feeding speed | X axis | m/min | 50 |

Yaxis | m/min | 30 | |

Z axis | m/min | 18 | |

G axis | r/min | 100 | |

Blade change time | s | 10 | |

Main spindle | power/rev | KW /rpm | 5.5/18000 |

Servo motor (Yaskawa) | X | KW | 0.85 |

Y | KW | 0.75 | |

Z | KW | 0.75 | |

Catapillar motor | KW | 0.25 | |

Tool Magazine | 旋转刀库 | 6工位 | |

Drill and mill cutter head | Max diameter | mm | Ø ~12 |

voltage/totol power | 380V 50HZ/10KW | ||

Overall dimension | mm | 6200x1500x1600 | |

weight | KG | 4000 | |

Necessary power source | power | KVA | 20 |

Air pressure | Kg/cm2 | 6~8 | |

3、Equipment configuration

Main component brand