FUNCTION:

1.Suitable used for milling ,drilling ,tapping,cutting on aluminum alloy profiles,PVC,light alloy profiles . it can completed 0°--180° processing after one loading ,ensure the high efficiency.

2.Adopts Siemens CNC system, with powerful function ,Excellent man-machine operation experience . Fast data processing and excellent product reliability.

3.Adopts HSD Italian 7.5kw high speed and efficiency main spindle.

4.Adopts 6-position automatic tool changer ,fast changes tools automatically .

5.Adopts automatic positioning and pressing system, identify the position of the worktable Automatically, ensure fast positioning and pressing.

6.Adopts protection device ,safety instruction and malfunction alarm function ,ensure operator ‘s safety and reduce working noise .

Main Technical Parameter

Description | Unit | data | ||

Work area | Processing length of X-axis | mm | 8500 | |

Processing length of Y-axis | mm | 650(3-axis processing ) | ||

Processing length of Y-axis | mm | 600(4-axis processing ) | ||

Processing length of Z-axis | mm | 400 | ||

Angle scope of A-axis | degree | 0 -180 | ||

Work accuracy | Positionning | mm | ±0.1 | |

Re-positioning | mm | ±0.05 | ||

Extent of prependcicularity | mm/mm | 0.1/100 | ||

Rough | mm | 0.1 | ||

Extent of circularity | um | Ra 12.5 um | ||

Feeding speed | X-aixs | m/min | 60 | |

Y-axis | m/min | 30 | ||

Z-axis | m/min | 20 | ||

A-axis | r/min | 300 | ||

Tool system | Tool quantity | 6-position | ISO30 ×6 | |

Tool change time | s | 20 | ||

Collet | Max. Diameter | mm | Ø 16 | |

Spindle (Italian SHD) | Power /rotary speed | KW /rpm | 7.5/24000 | |

Servo motor (SIEMENS) | X | KW | 3 | |

Y | KW | 2 | ||

Z | KW | 2 | ||

A | KW | 1 | ||

Voltage /Power supply | Total | 380V 50HZ/10KW | ||

Overall dimension | mm | 10986×2497×3200 | ||

Overall dimension of electric box | mm | 600x1400x1800 | ||

Overall dimension of control box | mm | 600x700x980 | ||

Power source | Power | KVA | 20 | |

Air pressure | Kg/cm2 | 6~8 | ||

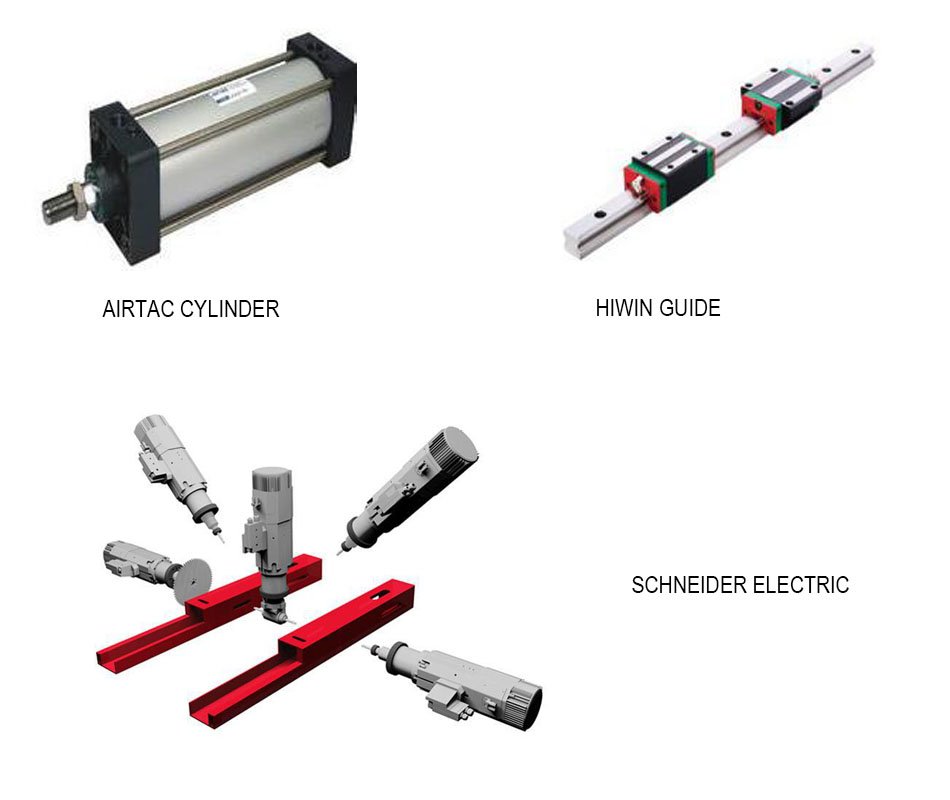

Main component brand: