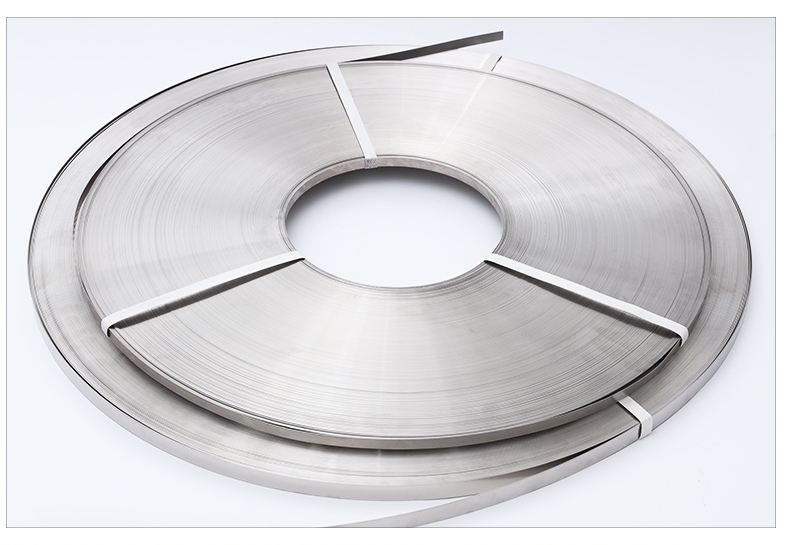

304 stainless steel strip is a universal stainless steel material, rust resistance than the 200 series of stainless steel material is stronger. High temperature resistance up to 1000-1200 degrees. It has excellent corrosion resistance and inter-granular corrosion resistance. And in the concentration of less than 65% of the boiling temperature of nitric acid, 304 stainless steel still has a strong corrosion resistance

1. 304 is a widely used stainless steel/heat-resistant steel.

2. stamping/bending and other thermal processing, no heat treatment hardening phenomenon.

3. for universal stainless steel, good requirements, comprehensive performance of equipment and parts.

301 stainless steel strip is a metastable austenitic stainless steel with complete austenite structure under the condition of full solid solution. SUS301 can improve the strength and hardness of steel through cold deformation processing, and retain enough plasticity and toughness, and has good rust resistance,, but the reducing medium corrosion resistance is not good, so it is not recommended for corrosion harsh environment.

1. Widely used in food production equipment, general chemical equipment, nuclear energy, spring and other industries.

2. It is suitable for the equipment that can bear high load, reduce equipment weight and not rust at the same time.

3. It can absorb more impact energy and provide safe guarantee for equipment and personnel.

201 stainless steel strip is a kind of nickel steel, which has the characteristics of acid and alkali resistance, high density, polishing no bubbles, no pinhole, etc., is the production of a variety of watch case, watchband bottom cover quality materials, etc., mainly used for decorative pipe, industrial pipe some shallow stretch products; Stainless steel originated in world war Ⅱ and was first developed successfully by the United States.

1. Widely used in the public catering industry, durable consumer goods, construction, automobile and other industries.

2. The product is magnetic after cold processing, especially suitable for railway vehicle related products.

3. SUS201 has higher manganese content and lower rust resistance and corrosion resistance than series 300 and 400.

316 stainless steel strip plastic, toughness, cold denaturation, welding process performance is good, 316 high temperature strength is good, 316L high temperature performance is a little poor, but corrosion resistance is better than 316, because the carbon content is low and contains 2%-3% molybdenum, improve the reducing salt and various inorganic acids and organic acids, alkali,salt corrosion resistance, at the same time high temperature strength.

SUS316 stainless steel is suitable for sea water, equipment, chemistry, dye, paper making, etc

1. The raw material of the product comes from posco, and good raw material determines good quality.

2. Good welding performance, all standard welding methods can be used for welding.