Your security gate is only as strong as the lock you use – Your steel gate lock is only as good as the gate you build.

Installing Electric Locks? Safe?

Power Supply

Check that you have the correctly specified power supply connected.

Check that you have enough power going all the way to the lock – correct voltage must be 12v AC to lock itself

Less than 12V and the lock might not always release correctly (unless the door lock has a function for reduced power supply)

More than 12V and the coil can heat up and burn out

Make sure Amperage is sufficient to avoid power drops (1.5 amp or 3 amp for long cables)

ALWAYS USE A VOLTAGE METER!

Wiring

Ensure that you use the correct thickness of cable

Use minimum of 1 mm2 (square) diameter flex up to 30m cable length

Use minimum 1.5 mm2 flex above 30m

Make sure that all wires are tucked away and not exposed or accessible

Exposed wires pose a security risk

Mind the Gap

Ensure that you have the recommended gap between the frame and the lock body so that the lock will load and set correctly

If the gap between the frame and the lock body is too narrow the latch can get stuck

If the gap between the frame and the lock body is too wide the latch won’t latch and set properly

Optimum gap for most electric locks is 3 – 4 mm

Optimum gap for Aluminium doors – 2mm

Optimum gap for Rim Electric locks can go up to 4.5mm

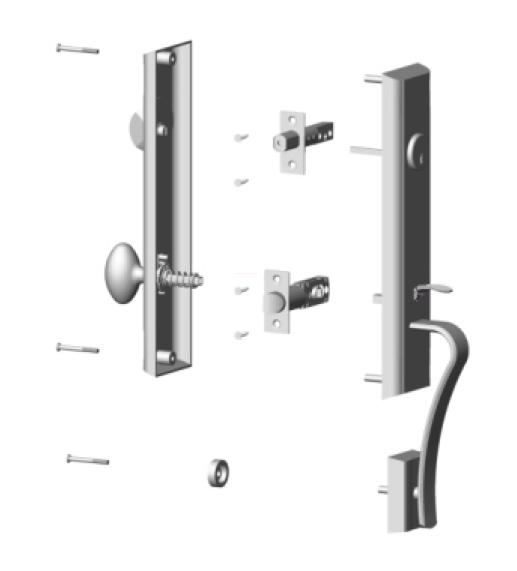

Installation

Make sure that the Cylinder Barrel is facing the right way up (with the CISA logo facing to the top)

If you are installing a Rim Electric Lock and the cylinder barrel sticks out it needs to be protected with a CISA weld-on protective box, otherwise it can become a security risk

If you are installing a Euro-Profile cylinder in a Mortise Electric Lock then you need to use a protective rose or Escutcheon

On Mortised Electric Locks make sure that you protect the coil of the locks as much as possible from weather – seal the tops of the gate tubing and make sure the top of the lock-style is sealed, otherwise rainwater will seep in and can damage the coil.

Maintenance

Ensure periodic maintenance and lubrication

USE WD40

Spray on Latch & Load pin, Dead Bolt and Cylinder (but avoid contact with the coil)

DO NOT spray onto the Coil (avoid the coil completely)

DO NOT use a Silicon based spray. This can cause more harm than good.

10 tips to making your security gate as safe as possible:

Ensure that all welding is thoroughly done by an experienced welder.

Ensure that your gate Frame is securely attached to the structure

Always ensure that you correctly specify your lock, and choose the strength of the lock according to your security requirement

Ensure that all surface mounted locks are concealed from the outside and that you use a protective 3mm steel plate if the gate is not solid to make sure there is no access to the locks.

Ensure that there are no gaps between the gate and the frame that will allow access to the lock from the outside with crowbars or similar levers. Instead, use of a 3mm Steel Overlap to cover any gaps.

Ensure that the Fixing Plate of the main door lock is welded to the gate securely

Ensure that the Strike Box of the lock is be welded securely

Ensure that the gate not corroded or sagging, and that the gate hinges are strong

Make sure that there are no cables or electrical wiring exposed and make use of a Cable Guard between the gate and frame