Moving bed biofilm reactor (MBBR) is a kind of biotechnology for wastewater treatment processes. It is suitable for municipal and industrial applications. It is also known as moving bed film reactor. It was created in the 1980s. MBBR provides an affordable and cost-effective solution for wastewater treatment. STP MBBR technology is the use of moving bed biofilm reactors in wastewater treatment plants.

MBBR wastewater treatment system can achieve efficient treatment results with low energy consumption. This technology is used to separate organic matters, nitrification and denitrification. The MBBR design consists of an activated sludge aeration system. The sludge is collected on a plastic carrier with a large internal surface area. The surface area in the carrier maximizes the touch of air, water, and the germs.

MBBR activated sludge is the use of MBBR media in an overloaded treatment plant during the upgrade.

The MBBR system is suitable for wastewater treatment of different qualities. The application is determined by the desired effects and regulations controlling the discharge. The system can be divided into multiple stages based on particular needs. These stages consist of individual water tanks which are separated by screens to make sure that bacteria stay in their particular tank.

MBBR Media Used in Wastewater Treatment

Aeration tank: The tank is much like an activated sludge tank. The aeration is used to maintain the motion of the activated sludge and carriers. The MBBR system divides the extra bacteria and sludge, and these bacteria and sludge are led into the last separator.

Special plastic carriers: They provide a surface for the growth of biofilms. The carriers are made of materials that have a similar density with water (1g / cm3), such as high-density polyethylene (HDPE) with a density of 0.9g / cm3. These carriers are transferred into the water tank via an aeration system. This ensures excellent contact between the wastewater and the biomass on the carriers.

Benefits of MBBR Technology

Compact structure saves space

Easy to maintain

Suitable for high loads

Scaling and scaling are easy. This is made possible by increasing the degree of filling of the carrier.

Reduce emissions costs

MBBR wastewater treatment system isn’t influenced by toxic shock

Independent procedure performance because there’s no sludge return pipe; MBBR eliminates bloated activated sludge (RAS)

It has efficient sludge retention time (SRT) to enhance the nitrification process

Lower sludge production

No need to recycle activated sludge-like systems

MBBR media installed to refurbish existing activated sludge ponds to increase their capacity

Design of MBBR Systems

The MBBR system employs a combination of activated sludge process (i.e. suspension growth) and a biological filter (i.e. adherent growth). It allows the entire storage tank volume for biomass growth by using the carriers for attached growth of biofilm. Movement of carriers is permitted by air bubbles throughout agitation.

The reactor can be of any shape and withstand different loads depending on the carrier filling conditions. The MBBR design of the reactor depends on the characteristics and location of the actual wastewater. These plants are equipped with rectangular screens mounted vertically or horizontally. The reactor can also be equipped with a cylindrical rod screen.

The MBBR carriers are cylinders with a cross shape on the inside and fins on the outside to increase the surface area. In the area not exceeding 465 square meters, the standard used is less than 70% of the carries per square meter. MBBR is used with septic tanks or pre-coagulation steps for pretreatment. MBBR technology can be designed with other non-mechanical or mechanical systems to enhance the reducing capacity of phosphorus and fecal coliforms.

Application of MBBR

Removal of Biological Oxygen Demand (BOD) - Only one wastewater pond with MBBR and clarification is required.

Nitrification - It uses two tanks, one for BOD removal and the other for nitrification.

Denitrification - It utilizes four aeration tanks within this arrangement before draining from the precaution with the denitrification, BOD reduction, nitrification and post-denitrification.

The MBBR wastewater treatment system is suitable for industrial and municipal applications.

Operation and Maintenance of MBBR

Frequently used MBBR does not require backwashing or backflow of sludge. Due to the coarse bubble aeration in the aeration zone, the operating cost of the wastewater treatment tank is low. The agitation constantly moves the carriage over the service, thereby eliminating blockages.

Upkeep of the MBBR system is mainly carried out in the form of screening, sludge treatment, and balanced water intake. It also involves maintaining integrated control systems and purifier systems. MBBR requires skilled personnel to routinely monitor the operation of pumps and blowers. MBBR technology has a self-maintenance mechanism at the biofilm level.

MBBR vs MBR

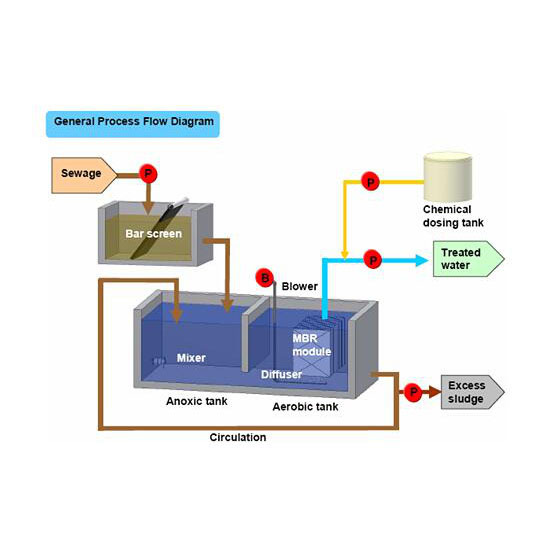

Membrane bioreactor relies on a blend of traditional activated sludge and biofilm media. The comparison between MBR and MBB can be made in the following aspects.

MBR’s capital investment is higher than MBBR

MBR’s screening requirements are higher than that of MBBR technology

MBBR systems do not require chemicals like MBR systems

Compared to MBBR, MBR systems are more difficult to operate

MBR requires recirculation pumps and blowers which does not apply to MBBR

Blowers are required for both systems

With the power off, MBR can last up to 24 hours, and MBBR can last up to 10 hours, after which bacteria form a bio-cake

MBR better transfers complex or toxic substances than MBBR

MBR effluent quality is excellent, but MBBR is only suitable for irrigation purposes

Both are susceptible to grease because MBR membranes can be cleaned or replaced very well, but for MBBR, the carrier needs to be replaced, and the plant requires ten days of restart time.

Conclusion

The amount of biomass plays an important role in the removal efficiency of the MBBR system, and the biomass can be increased by the volume of carriers per unit. Operator performance needs to be validated for specific wastewater treatment to suit different situations. The design of a water treatment plant should not be based on assumptions or estimates but should use the correct materials as a carrier and calibrate the required volume.

If there are regulations on wastewater discharge, MBBR technology is effective for wastewater treatment. MBBR wastewater treatment system is flexible and can be easily repositioned. For ecological reasons, MBBR can be used for wastewater treatment.