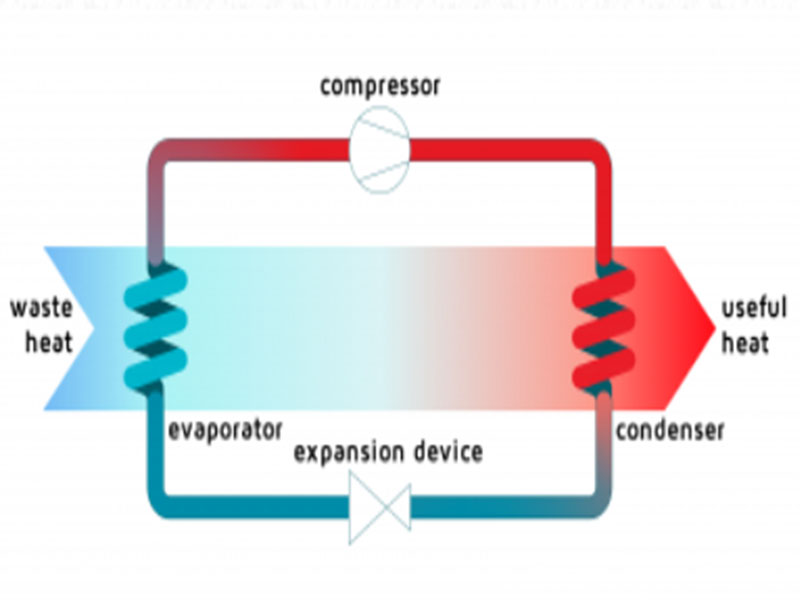

The mechanical heat pump is the most prevailing heat pump to be applied commercially. Its principle of operation: Inside a mechanical heat pump the pressure of a refrigerant is increased with the use of a compressor. Due to this increase in pressure, the condensation temperature rises. Most installations have an electric motor to drive the compressor. Two types of mechanical heat pumps are available: a system that with direct expansion of the refrigerant at the inlet of the evaporator (dx system) and a so called 'pump system' heat pump where liquid refrigerant is pumped to the evaporators. Both types are described in more detail below.

DX-system

The figure on the right shows a system with direct expansion. Direct expansion implies that the entire refrigerant volume at the outlet of the expansion device is fed to the evaporator. Due to the expansion, a large part of the fluid refrigerant evaporates, denoted as flash gas. The refrigerant, largely gaseous and partly fluid, is sent to the evaporator. Only the liquid part of the refrigerant has the ability to evaporate in the evaporator. When the refrigerant is totally evaporated and slightly super heater, the refrigerant flows to the compressor. The superheating is necessary to prevent the compressor from damage due to liquid slugging. The amount of refrigerant sent through the expansion device, is controlled by the degree of superheating measured at the outlet of the evaporator. The compressor capacity is controlled by the condensation temperature at the compressor outlet.

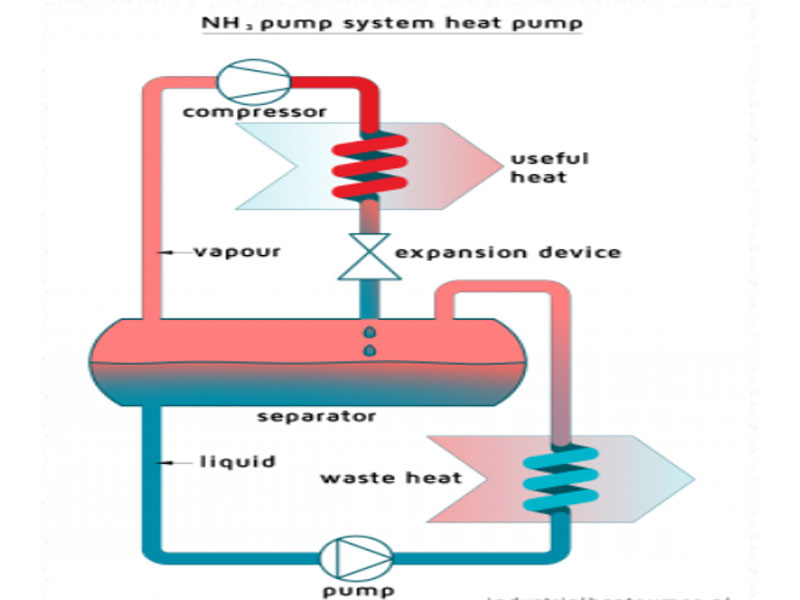

Pump system

The other type of the mechanical heat pump is the pump system heat pump. The figure on the left shows its principle of operation. A pump system contains a separator vessel. From this vessel, fluid refrigerant is pumped to the evaporator(s). Inside the evaporator the refrigerant is partly evaporated: a mixture of fluid and gaseous refrigerant flows back to the separator vessel. This vessel separates the refrigerant in liquid and vapor. The liquid is pumped to the evaporator again; the vapor flows to the compressor. An advantage of this system is that smaller evaporators can be used as compared to dx systems with the same capacity, due to the supply of fluid refrigerant solely. On the other hand, an additional refrigerant pump and separation vessel are needed. Pump system heat pumps are therefore most suitable for large scaled industrial applications. The majority of heat pumps with Ammonia are built as a pump system type. Ammonia dx systems are very sensitive as it comes to pollution of the expansion device. Besides, overheating of the refrigerant in dx systems causes high discharge temperatures that might demolish the compressor oil.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you’re interesting in heat pump products,please feel free to contact OSB heat pump. We are your best choice.