What is the use of nano air filtration?

Why is nano air filter so amazing?

What kind of air filter can be called nano air filter?

There are more and more nano air filters in the market. As a user, how do I distinguish them? ......

As early as the 1970s, nanotechnology was applied to the field of engine air filtration, and nano-filter paper was introduced. Over 40 years of continuous innovation and application, it has developed into a series of nano-filter papers (microfibers) suitable for different application scenarios (filter paper).

In recent years, due to the approach of national six-emission standards for road vehicles and four-stage emission standards for off-highway, the diesel engine industry and the corresponding filter industry have released F8, F9 or even “nano” class air filter cartridges, and filtration efficiency is increasing. High (that is, engine protection is getting better and better), while also emphasizing long life.

1. What kind of air filter can be called nano air filter?

According to the latest international standard ISO/TS80004-2015, the length from 1 nm to 100 nm is officially called nanometer. In the filter paper industry, fibers larger than 100 nm and less than 1 μm are recommended to be uniformly called fine fibers or microfibers. (1 micron = 1,000 nm)

Since everyone is accustomed to the name of nano-air filtration, all the references to nano-air filtration in this paper refer to the air filter made of fine fiber filter paper. For the sake of standardization, everyone must avoid using the term “nano” in the contract, drawings, and especially the official text of import and export.

2. What is nano air filtration?

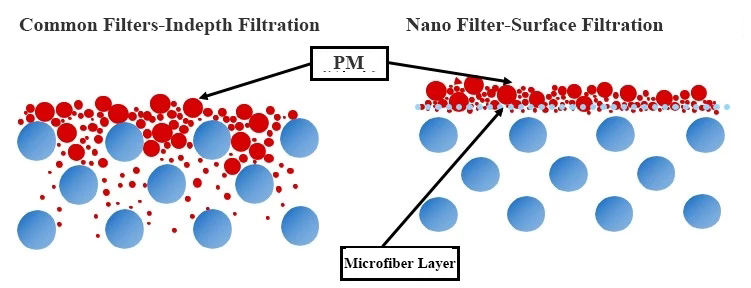

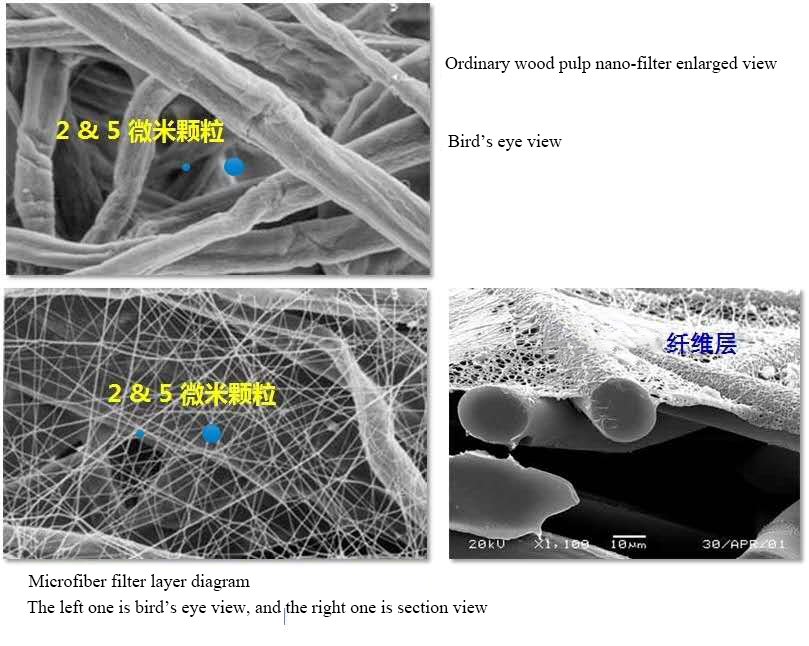

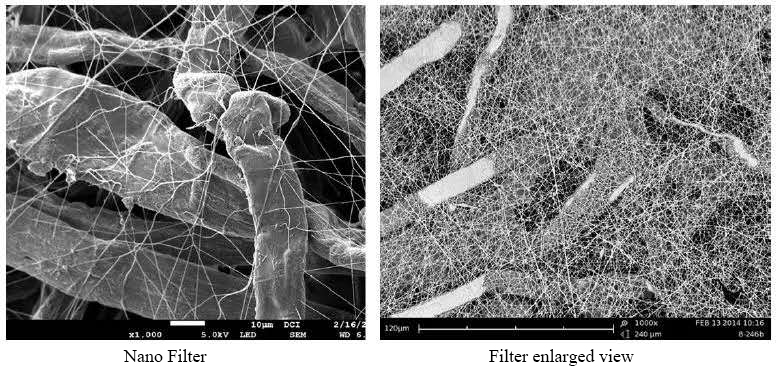

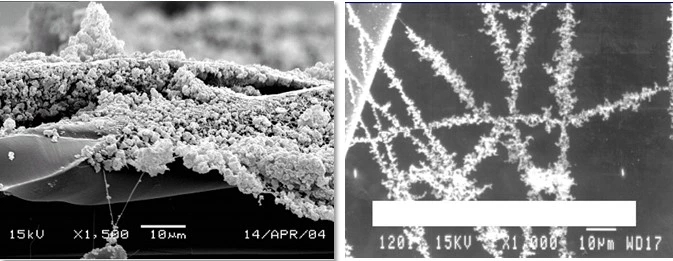

A layer of fine fiber coating is added to the surface of ordinary wood pulp fiber filter paper by electrospinning, etc.

The presence of a fine fiber coating can greatly reduce the nominal pore size of the filter paper, greatly increase the specific surface area, and can intercept more fine particles on the surface of the filter paper, changing the filtration mechanism from deep filtration to surface filtration.

At the same time, due to the slip effect, the fine fiber coating which appears to be laminated on the surface of the wood pulp fiber layer does not increase the inlet resistance of the filter paper, thereby achieving a perfect balance between filtration efficiency and pressure drop.

3. What are the benefits of nano air filtration?

The first is to significantly increase filtration efficiency (including initial filtration efficiency and full life efficiency), or to significantly reduce the amount of dust entering the engine.

From the full-life filtration efficiency of 99.9%, which is generally required by the OEM, to 99.99% of the filter paper claims and 99.999% of the recent nano-filter paper, the protection level of the engine is increased by 10 times!

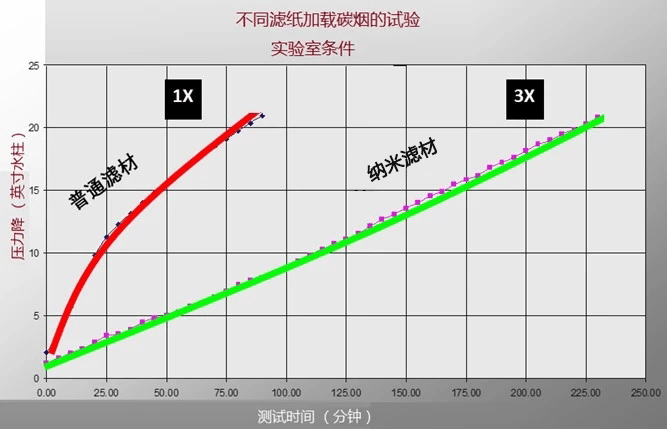

The second major benefit of nanofilter paper is that it increases the maintenance cycle of the filter several times in a fine particle or soot-based environment.

Numerous studies and road tests have shown that the traction vehicles on a good road surface are mostly in the air of the engine, and the diameter of the particulate matter is mostly 10 μm or less, especially the carbon smoke emitted from the exhaust gas of a large number of diesel engines. Nano-filter paper can accommodate more fine particles and soot due to its large specific surface area and the same resistance.

Under normal conditions, ordinary filter paper and nano filter paper were tested for soot loading. The abscissa is time and the ordinate is the corresponding resistance rise.

Under the microscope, it is clear that the nanofibers contain fine particles/soot.

Laboratory tests on recycled filter elements indicate that the resistance at this time is still below the critical maintenance resistance.

Working conditions: a certain brand of heavy trucks, traction logistics vehicles, Suzhou to and from Shenzhen.

4. Conclusion

Nano air filter, due to its high efficiency and long life, not only protects the engine but also reduces the downtime of end users, and has been recognized and accepted by more and more users. However, the products on the market are mixed, and it is difficult for ordinary users to distinguish whether the specific air filter products really contain reliable nanotechnology (fine fiber technology). Nanofibers, because of their extremely small diameter, are difficult for ordinary users to quickly distinguish. There are more feasible methods for the majority of users to believe the brand, reputation and the results of their own experiments.

Source of the article transferred from the Internet