(Original title: Nanofiber Absorbent Material, Which Makes Paper Diapers and Hygiene Products Safer and More Environmentally Friendly)

According to a study published in Applied Materials Today, a new material made from nanofibers can replace the harmful materials in current diapers and personal hygiene products.

The author of the paper, a researcher from the Indian Institute of Technology, said the new material has less environmental impact and is safer for humans than existing materials.

In the past few decades, disposable diapers, sanitary napkins, and other personal hygiene products have been rendered water absorbent due to the use of superabsorbent polymers (SAP). These materials are capable of absorbing liquids several times their own weight. On average, each diaper can absorb 30 times its own weight of liquid.

But these materials are not biodegradable. In an ideal situation, a diaper takes 500 years to degrade. And SAP materials are also associated with health problems, such as toxic shock syndrome, and were therefore banned from being used in the manufacture of tampon in the 1980s.

According to these researchers, a new material made from electrospinning cellulose acetate nanofibers does not have these drawbacks of SAP. They analyzed the material in the study and found that it could replace SAP materials for the manufacture of feminine hygiene products.

Chandra Sharma, co-author of the paper, said, "The long-term use of these products can lead to toxic shock syndrome and other health problems, so there is a need to develop a safe material that can replace SAP."

“Our materials not only replace the dangerous, biodegradable, highly water-absorbent polymers in sanitary napkins currently on the market, but also perform better than current materials, even in terms of comfort and water absorption.”

This nanofiber is a thin, long material made by a technique called electrospinning, which uses static electricity to extract fibers from a liquid. Because the surface area and volume of this material is very large, researchers believe it is more absorbent than existing materials. They compared this material to sanitary napkins on the market and found that the water absorption of this material is indeed stronger.

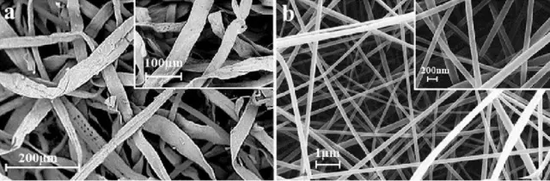

The sanitary napkins currently available on the market are made of flat ribbon fibers having a diameter of about 30 microns. The new nanofibers are only 150 nanometers in diameter and 200 times thinner than the former. This new material is more comfortable than currently available on the market and has less residue after use.

【Figure】(a) Commercially available sanitary napkin material has a fiber diameter of 30 to 40 microns; (b) A prototype material made of electrospinning nanofibers having a diameter of about 200 nanometers.

Image Source: Yadav, Shital et al, Applied Materials Today, September 2016

The new nanofibers (over 90%) are more permeable than conventional materials (80%), which makes them more water absorbing. This was confirmed in the experiment. Saline and synthetic urine were used in the experiments, and the electrospinning fibers were much more absorbent than the products on the market. They also tested two other nanofibers with SAP added and found that their water absorption is not as good as pure nanofibers.

“Our results show that the performance of electrospinning fibers is better than the general products on the market in terms of water absorption and comfort. We think it is an ideal substitute for the current hazardous materials,” Dr. Sharma said, “This material can be much safer when making the use and disposal of personal hygiene products, we hope it will benefit the environment and human health on a global scale.”