Applications Introduction

◆ The nanofiltration membrane produced by the equipment can replace the melt-blown cloth as the core layer of the mask.

◆ Width: 1200 mm;

◆ Equipment composition: winding and unwinding system + liquid supply cart + electric cabinet + spinning workshop + drying device;

◆ Production capacity: 4000~8000㎡/24h (meet the material required for the production of 100,000 to 200,000 face masks).

Advantages

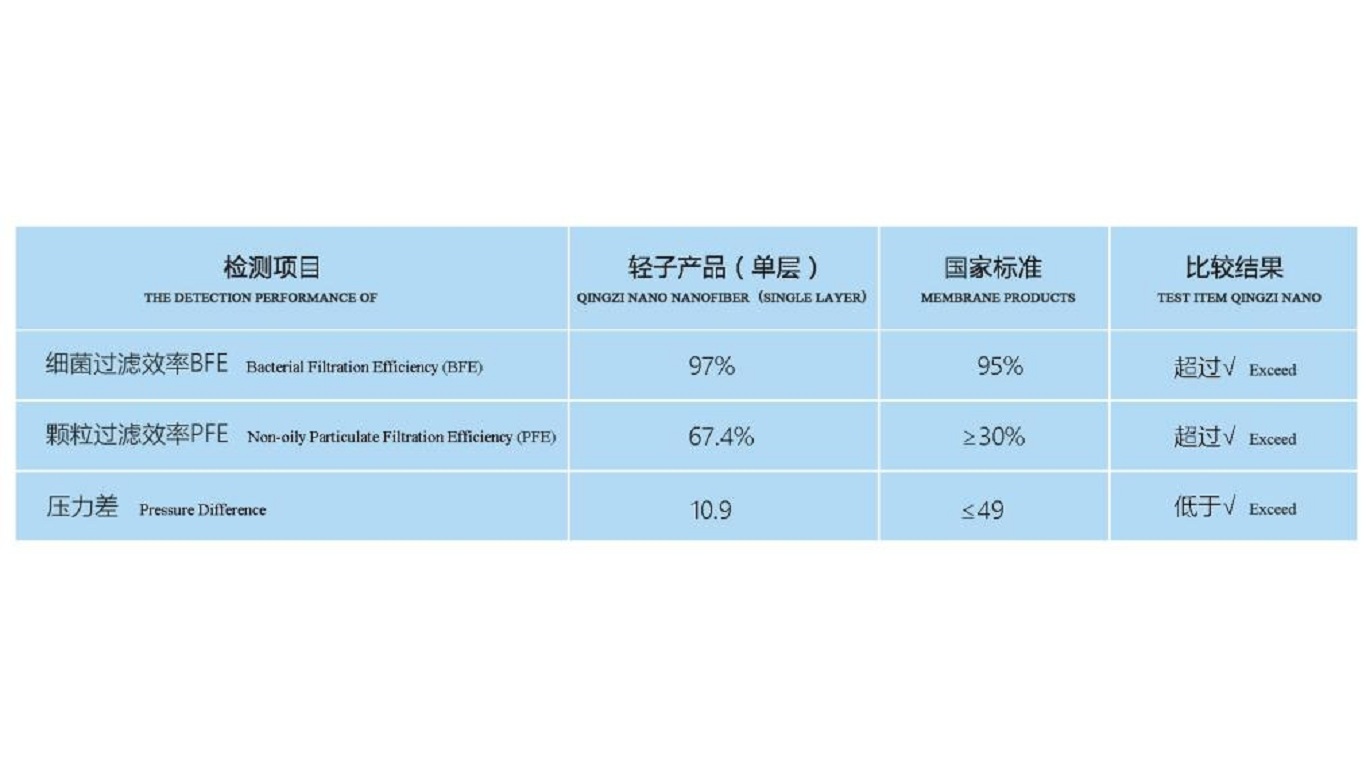

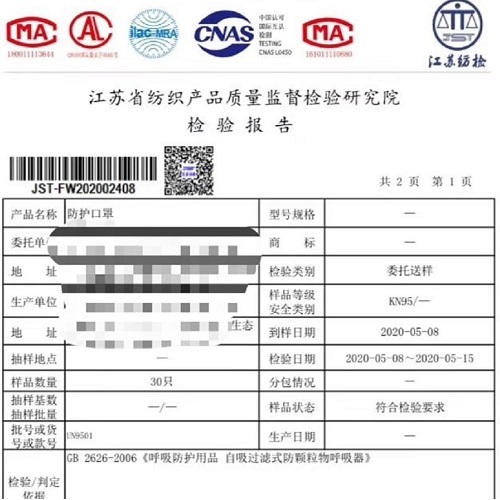

It conforms to YY0469 standard of the medical-surgical mask;

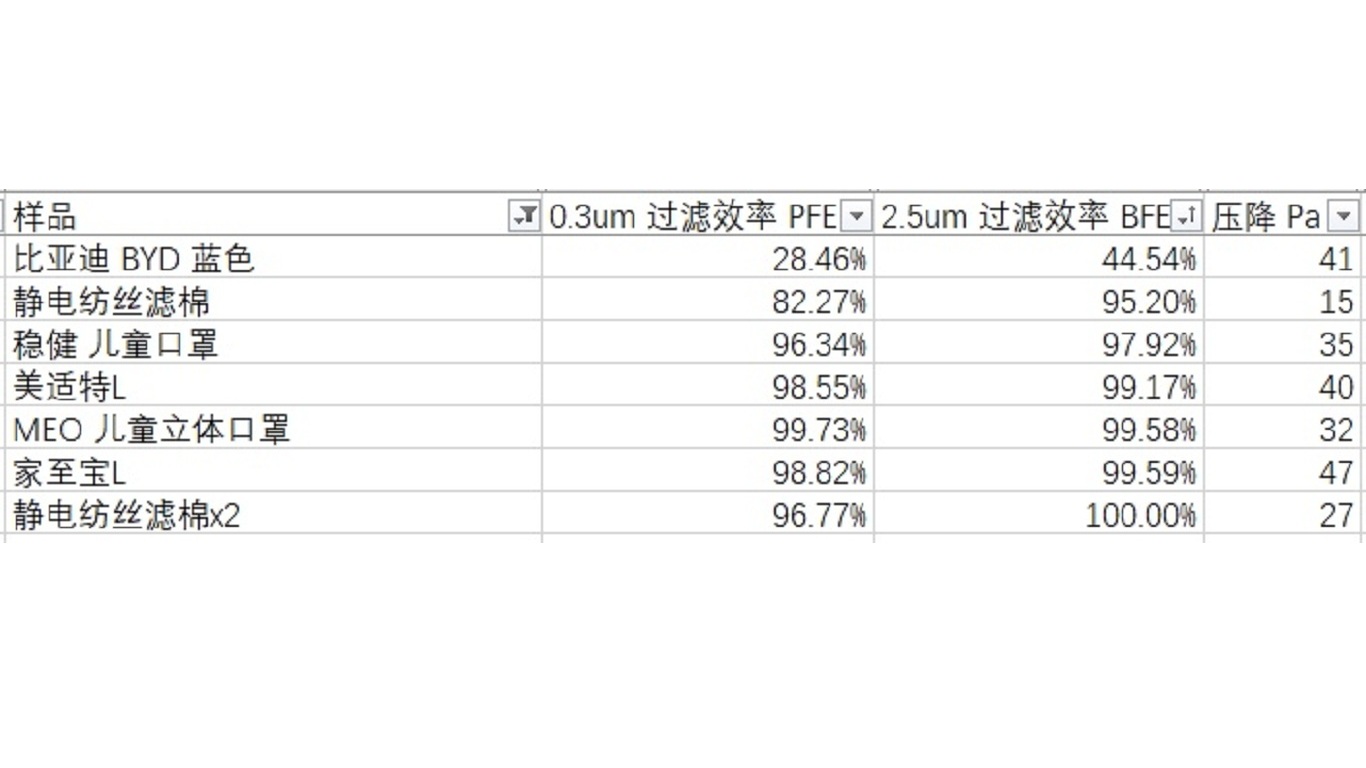

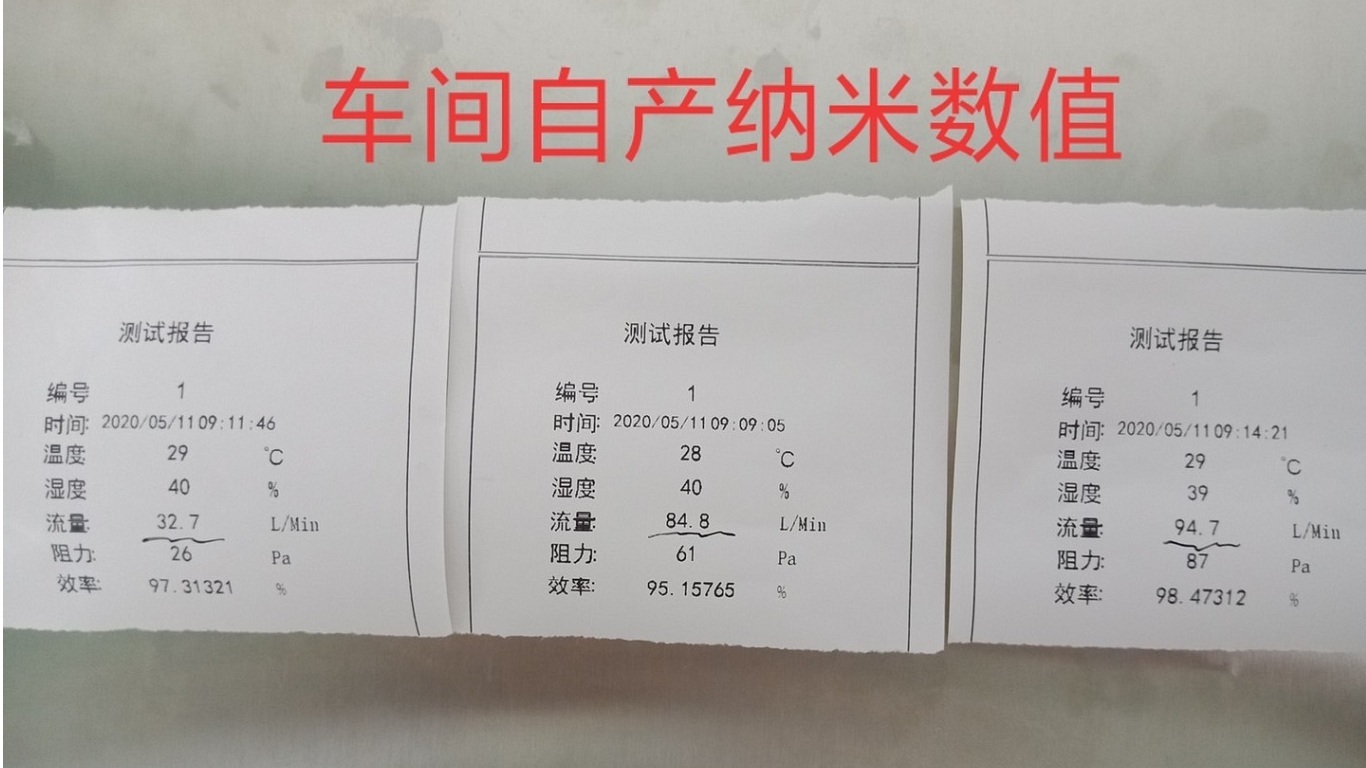

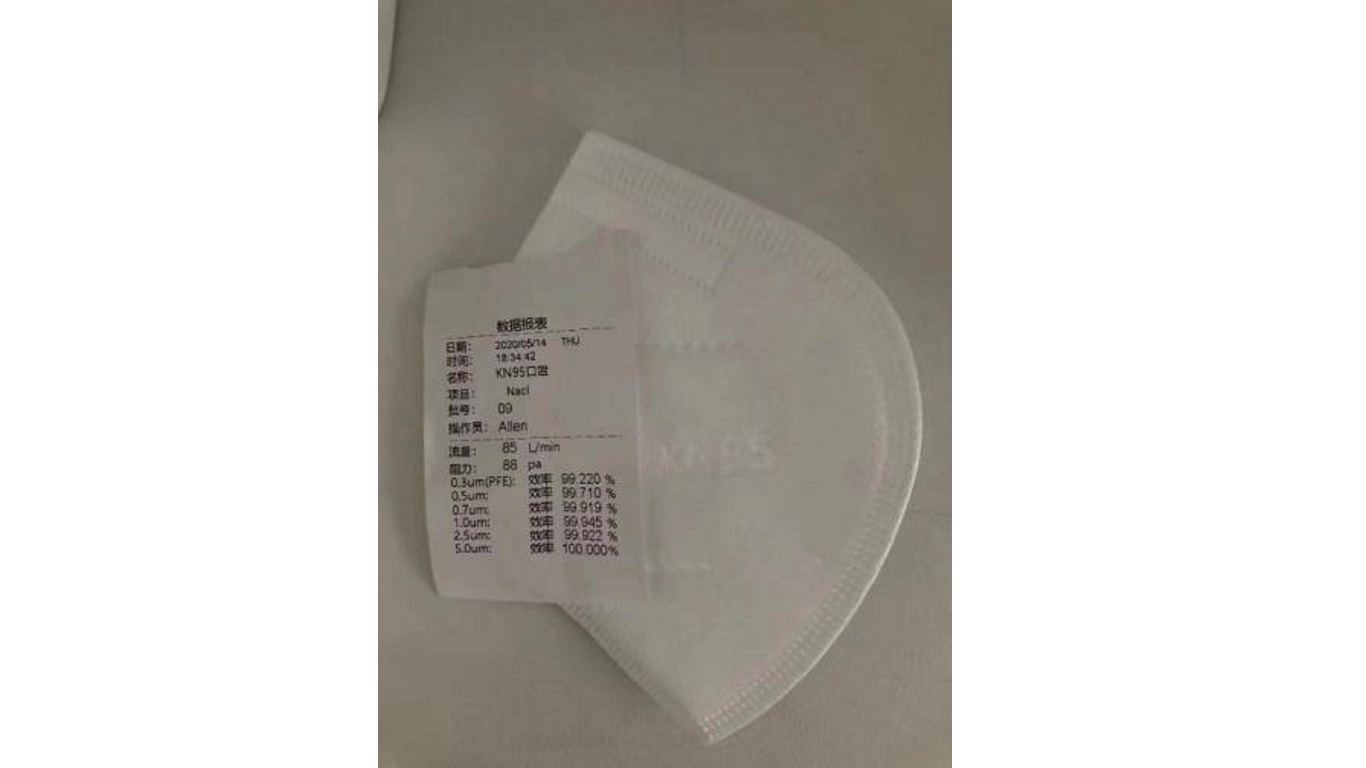

The filtration efficiency of the double layer nanofiber membrane can reach more than 95%, which conforms to the national KN95 requirements;

Mainly depends on the physical interception, does not need the static electret, does not exist the static electricity vanishes.