Stamping processing is the production technology of product parts that are deformed and deformed directly in the mold by means of the power of conventional or special stamping equipment to obtain a certain shape, size and performance. Sheets, molds and equipment are the three elements of stamping. According to the stamping processing temperature, it is divided into hot stamping and cold stamping. The former is suitable for sheet processing with high deformation resistance and poor plasticity; the latter is carried out at room temperature, which is a common stamping method for thin sheets. It is one of the main methods of metal plastic processing (or pressure processing) and is also part of material forming engineering technology.

The mold used for stamping is called a stamping die, or a die for short. Dies are special tools for batch processing materials (metal or non-metal) into the required punches. Dies are essential in stamping. There are no dies that meet the requirements. Batch stamping production is difficult to carry out; without advanced dies, advanced stamping processes cannot be achieved. The stamping process and the mold, stamping equipment and stamping materials constitute the three elements of stamping processing, and only when they are combined with each other can the stamping parts be obtained.

Processing characteristics:

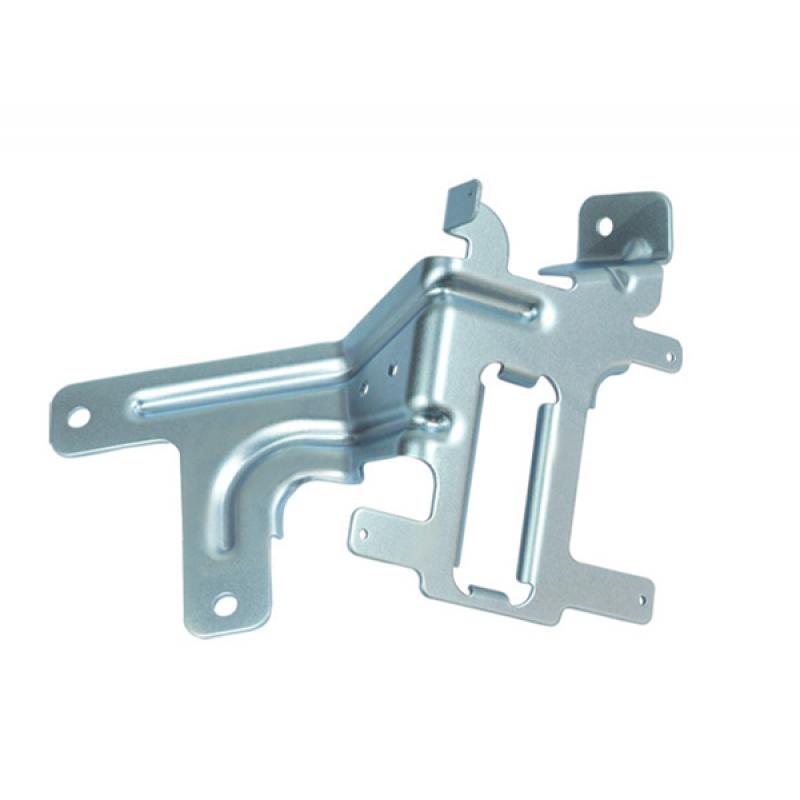

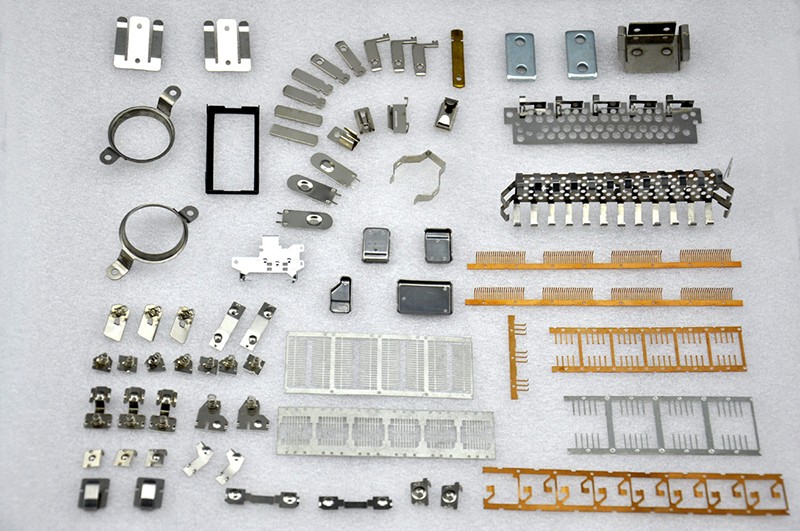

Compared with castings and forgings, stamping parts are thin, uniform, light and strong. Stamping can produce workpieces with ribs, ribs, undulations or flanging that are difficult to manufacture by other methods to increase their rigidity. Thanks to the use of precision molds, the precision of the workpiece can reach micron level, and the repeatability is high and the specifications are the same. It is possible to punch out the holes and the bosses. Cold stampings are generally no longer machined or require only a small amount of machining. The accuracy and surface condition of hot stampings are lower than that of cold stampings, but they are still superior to castings and forgings, and the amount of cutting is small.

Stamping is an efficient production method. It adopts composite molds, especially multi-station progressive molds. It can complete multiple stamping processes on one press (single or multi-station) to realize unwinding and rectification of strips. Flat, blanking to fully automatic production of forming and finishing. High production efficiency, good working conditions, low production costs, and generally can produce hundreds of pieces per minute. Compared to other methods of machining and plastic working, stamping has many unique advantages both technically and economically. The main performance is as follows:

(1) The stamping process has high production efficiency and is easy to operate, and is easy to mechanize and automate. This is because the stamping relies on die and stamping equipment to complete the processing. The number of strokes of ordinary presses can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute, and each press stroke is Maybe get a punch.

(2) Since the die ensures the size and shape accuracy of the stamping part during stamping, and generally does not damage the surface quality of the stamping part, and the life of the die is generally long, the quality of the stamping is stable, the interchangeability is good, and it has “the same”. Characteristics.

(3) Stamping can process parts with large size range and complex shape, such as stopwatches as small as watches, as large as car longitudinal beams, covering parts, etc., plus the cold deformation hardening effect of the material during stamping, the strength of stamping and The stiffness is high.

(4) Stamping generally has no chip scraps, less material consumption, and no need for other heating equipment. Therefore, it is a material-saving and energy-saving processing method, and the cost of stamping parts is low.

Due to the superiority of stamping, stamping processing is widely used in various fields of the national economy. For example, in the aerospace, aviation, military, machinery, agricultural machinery, electronics, information, railway, post and telecommunications, transportation, chemical, medical equipment, household appliances and light industry departments have stamping processing. Not only is it used by the entire industry, but everyone is directly linked to stamping products. There are many large, medium and small stamping parts on airplanes, trains, cars and tractors. The body, frame and rim of the car are stamped and processed. According to relevant survey statistics, 80% of bicycles, sewing machines and watches are stamped parts; 90% of TV sets, tape recorders and cameras are stamped parts; there are food metal cans, steel-fired boilers, enamel bowls and stainless steel tableware. All are stamped and processed products using molds; even the hardware of the computer is not lacking in stamping parts.

The problems:

1. The mold problem

The molds used in stamping processing are generally specialized. Sometimes a complex part requires several sets of molds to be formed, and the mold manufacturing has high precision and high technical requirements, and is a technology-intensive product. Therefore, only in the case of large batch production of stamping parts, the advantages of stamping processing can be fully reflected, thus obtaining better economic benefits.

2. Security issues

There are also some problems and shortcomings in stamping. Mainly manifested in the noise and vibration generated during stamping processing, and the operator's safety accidents occur. However, these problems are not entirely due to the stamping process and the mold itself, but mainly due to the traditional stamping equipment and backward manual operations. With the advancement of science and technology, especially the development of computer technology, with the advancement of mechatronics technology, these problems will be solved as soon as possible and perfect.

3. High-strength steel stamping

Today's high-strength steel and ultra-high-strength steel achieve the light weight of the vehicle and improve the collision strength and safety performance of the vehicle, thus becoming an important development direction of the steel for the vehicle. However, with the improvement of the strength of the sheet, the conventional cold stamping process is prone to cracking during the forming process, and cannot meet the processing requirements of the high-strength steel sheet. In the case where the molding conditions cannot be satisfied, the hot stamping forming technology of ultra-high-strength steel sheets has been gradually studied internationally. This technology is a new process that combines forming, heat transfer and tissue phase transformation. It is mainly used in the process of forming a mold through a mold by utilizing the characteristics of high-temperature austenite, plasticity increase of sheet material and reduction of yield strength. However, thermoforming requires in-depth study of process conditions, metal phase transitions, and CAE analysis techniques. Currently, this technology is monopolized by foreign manufacturers, and domestic development is slow.

In the past, in the production of deep-drawn or over-punched workpieces, it was considered that pressure-resistant (EP) lubricants were the best choice for protecting molds. Sulfur and chlorine EP additives have been mixed into pure oils to improve mold life for a long time. However, with the emergence of new metals - high-strength steel, strict environmental requirements, the value of EP oil-based lubricants has been reduced, and even lost market.

In the formation of high-strength steel at high temperatures, EP oil-based lubricants lose their performance and do not provide physical mold protection diaphragms in extreme temperature applications. The extremely warm IRMCO high solids polymer lubricant provides the necessary protection. As the metal deforms in the stamping die and the temperature rises, the EP oil-based lubricant will become thinner, and in some cases it will reach a flash point or burn (smoke). IRMCO water-based stamping lubricants generally begin to spray with a much lower consistency. As the temperature rises during the forming process, it becomes thicker and tougher. In fact, polymer polymer extreme temperature lubricants are "hot looking" and stick to the metal to form a diaphragm that reduces friction. This protective barrier allows the workpiece to be stretched, without cracking and bonding during the formation of the most demanding workpieces, to control friction and metal flow. Effectively protects the mold, prolongs the life of the mold and improves the strength of the stamping.

Process classification:

Stamping is mainly classified according to the process, and can be divided into two major categories: separation process and forming process. The separation process is also referred to as blanking, the purpose of which is to separate the stamped parts from the sheet along a certain contour line while ensuring the quality requirements of the separated sections. The purpose of the forming process is to plastically deform the sheet without breaking the blank to produce a workpiece of the desired shape and size. In actual production, it is often the case that multiple processes are integrated into one workpiece. Punching, bending, shearing, drawing, bulging, spinning, and correction are several major stamping processes.

Separation process:

A basic stamping process for separating materials using a mold, which can be directly formed into flat parts or prepared for other stamping processes such as bending, drawing, forming, etc., or can be cut, trimmed, etc. on the formed stampings. Blanking is widely used in the automotive, household appliances, electronics, instrumentation, machinery, railway, communications, chemical, light industry, textile and aerospace industries. Punching processing accounts for about 50% to 60% of the entire stamping process.

Forming process:

Bending: A plastic forming method that bends sheet metal, pipe and profile into a certain angle, curvature and shape. Bending is one of the main processes widely used in the production of stampings. The bending of the metal material is essentially an elastoplastic deformation process. After unloading, the workpiece will produce a direction of elastic recovery deformation, called rebound. Rebound affects the accuracy of the workpiece and is the key technology that must be considered in the bending process.

Deep drawing: Deep drawing, also called drawing or calendering, is a stamping processing method of using a mold to make a flat blank obtained after punching into an open hollow part. Thin-walled parts of cylindrical, stepped, tapered, spherical, box-shaped and other irregular shapes can be made by the drawing process. If combined with other press forming processes, it is also possible to manufacture parts with extremely complex shapes. In stamping production, there are many types of deep drawing parts. Due to the different geometrical characteristics, the position of the deformation zone, the nature of the deformation, the distribution of the deformation, and the stress state and distribution of the various parts of the blank have considerable and even essential differences. Therefore, the process parameters, the number of processes and the order determination method and the mold design principles and methods are different. According to the characteristics of deformation mechanics, various deep-drawn parts can be divided into four types: straight-walled rotating body (cylindrical part), straight-walled non-rotating body (box-shaped body), curved body (curved surface part) and curved non-rotating body. Types of.

The pull shape is to apply a pulling force to the sheet by the pulling die, so that the sheet material generates uneven tensile stress and tensile strain, and the sheet and the pull mold conforming surface gradually expand until it completely conforms to the pull mold surface. The object of the pull shape is mainly a double-curvature skin with a certain plasticity, a large surface area, a gentle and smooth curvature change, and high quality requirements (accurate shape, smooth flow line, stable quality). The pull shape is relatively low in cost and flexibility due to the relatively simple process equipment and equipment used, but the material utilization rate and productivity are low.

Spinning is a metal turning process. During the processing, the blank rotates actively with the spinning mold or the spinning head rotates around the blank and the spinning mold, and the spinning head makes a feeding motion with respect to the core mold and the blank, so that the blank is continuously deformed locally to obtain the required hollow rotation. Body parts.

Shaping is the secondary dressing of the shape of the product using the shape of the established tool. Mainly reflected in the pressure plane, the foot and so on. For the resilience of some materials, there is no guarantee that the molding quality will be used once.

The bulging is a method of processing a part by using a mold to stretch and thin the sheet to increase the surface area. Commonly used are undulating forming, bulging of a cylindrical (or tubular) blank, and drawing of a flat blank. The bulging can be achieved by different methods, such as rigid bulging, rubber bulging and hydraulic bulging.

Flanging is a plastic working method of bending a material of a narrow strip region of a side of a thin plate blank or a preform on a billet into a vertical side along a curve or a straight line. Flanging is mainly used for edge reinforcement of parts, removing trimmings and making parts on the parts that are assembled and connected with other parts or three-dimensional parts with complex and special shapes and reasonable space, and at the same time improving the rigidity of the parts. It can also be used as a means of controlling cracking or wrinkling when forming large sheet metal. Therefore, it has been widely used in industrial sectors such as automobiles, aerospace, aerospace, electronics and household appliances.

The necking is a stamping method that reduces the diameter of the flanged hollow member or the open end of the tube blank that has been stretched. The diameter of the end of the workpiece before and after the shrinkage should not be too large, otherwise the end material will wrinkle due to severe compression deformation. Therefore, necks that are reduced from a larger diameter to a smaller diameter often require multiple neckings.