Normally after one new thermal paper slitting rewinding machine produced,we will test it and start to pack the machine well until the thermal paper roll slitting rewinding machine is approved quality. Now we introduce the packing for the finished thermal paper roll slitting rewinding machine.

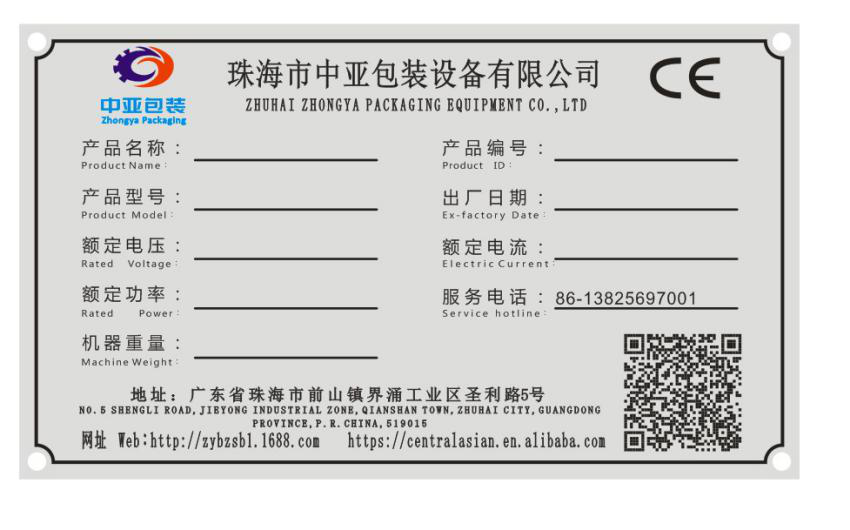

Firstly, we will binding one iron duty plate on the machine. This plate showing the machine model number ,production date and our factory name. The duty plate for our thermal paper slitting machine as below:

Secondly, we will spread the lubricating oil on the machine and then packing it by the stretch film. All the thermal paper roll slitting rewinding machine body will be packed well by the stretch film. Then the thermal paper roll slitting rewinding machine will not be soaked during the long transportation ship.

Last, we will pack the machine by our wooden box and make the mark on the wooden box.

When receiving this thermal paper slitting machine, the user should open the wooden box and check the quantity according to the loading list.

While moving this thermal paper slitting machine to the installation position, the machine should avoid to be damaged. While hoisting the machine, the four rings screws of the machine can be used.

This thermal paper roll slitting machine should be installed on the cement base (no need to lay foundation bolts in the earth beforehand, it can be adopted by expand bolts). Fasten each part with bolts and insert the relevant electrical plug-in unit well.

In order to slit accurately, the machine should be keep in level. A spanner can be used to adjust the base level bolts and a level can be used to correct it. While rectifying its horizontal, you can put the level on the wall board and rollers to check the whole thermal paper roll slitting machine’s horizontal. After having rectified its horizontal, you can fasten each base bolt and the upper bolts with nuts. Then you can use expand bolts to fix position.Clean all greasing parts and joints first and thereafter oil then again before starting of machine. To connect the air compressor – gas pressure 0.8mpa and 0.12m 3 min. Seek assistance from air compressor supplier for connection.