the blackwater cooling of paper industry, bleaching use salts, heating and cooling of lye, heat recovery of cellophane waste liquid, heating cooking acid, cooling of aqueous sodium hydroxide solution, recovery the waste liquid of bleached paper, condensation of exhaust gas, the waste liquid of the preheated concentrated pulp, all can apply to plate heat exchanger or a plate-shell heat exchanger. the evaporation concentration treatment for papermaking black liquid, since the black liquid contains dissolved fibers, colloids and strong corrosiveness, it is easy to cause blockage by using conventional heat exchanger, so free flow plate heat exchanger and pillow plate heat exchanger can be selected ( Pillow case).

Application

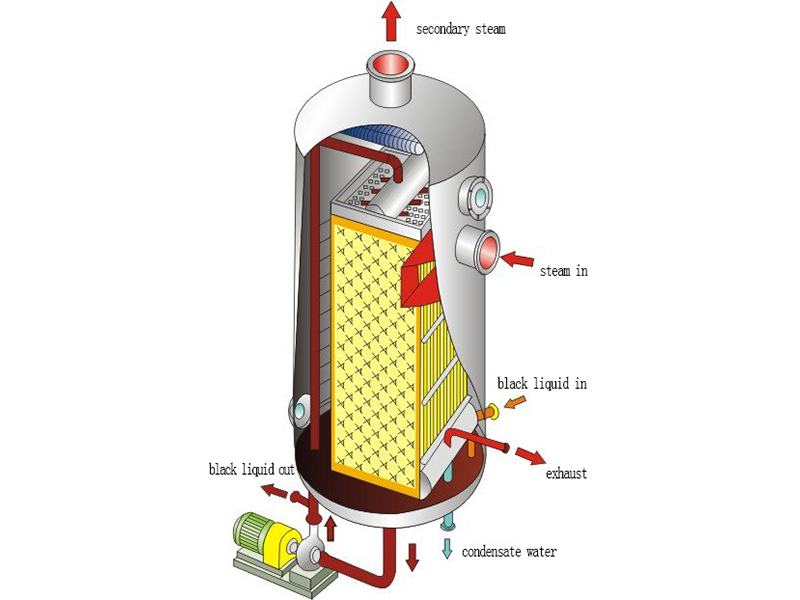

In the field of papermaking black liquid recycling, the embossed plate evaporator is used as black liquid concentration device,making the black liquid of low concentration to improve concentration, achieve high concentration black liquid incineration recovery, improve the incinerator efficiency, Large amount of recovery of caustic soda, reducing the operating costs of paper companies.

lye recovery during the papermaking process accounts for a considerable proportion of the total cost. The papermaking cooking liquid, the paper in the process, and wastewater of cellulose products have high recycling value. However, due to contains particulate impurities, viscous materials and other substances, the recycling of waste heat has great difficulties. Our pillow plate evaporator can solve the problem of easy clogging, easy scaling, and difficult cleaning. It can also be used as diluted black liquid heat exchanger, pure water heat exchanger, washing heat exchanger in a black liquid concentration process.