AIR COOLED CHILLER

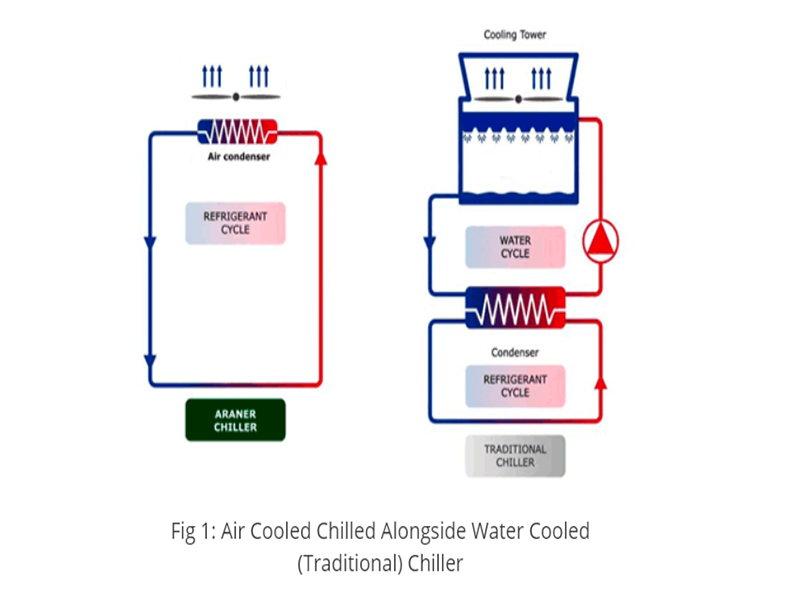

Where aesthetics and environmental conditions or water access restrictions exist, air-cooled chiller may be applied. Both air-cooled and water-cooled chillers depend on an air stream as a means of heat transfer.

The difference is that the water-cooled chillers or rather the cooling towers use a humid air stream (ambient air stream + water spray) while the air-cooled chillers use a current of ambient air.

Normally water-cooled chillers are cheaper and more efficient, with the disadvantage of high water consumption.

Unfortunately, some people still believe that air cooled chillers cannot offer quite good efficiencies. What such people only need to check is the performance of these chillers two decades ago is the progressive increase in NPLV rating of air-cooled chillers over the years.

In summary, here are the benefits of using air-cooled chillers:

• No cooling towers

• Better environmental stability-no water wastage

• Low maintenance costs

• Easier to operate and control-tower freezing and tower bypass absent

• Chemical costs avoided

• Water costs avoided, especially in cities

• No water problems to deal with in case of disaster

After entering the condenser at about 27°C (80.6°F), the water leaves at 32°C (89.6°F) and heads to the cooling tower. Note that at no time do the refrigerant and the condenser contact directly. Heat exchange is only through a pipe wall. The condenser water, with the unwanted heat, goes to the cooling tower for further heat rejection.

IN THE COOLING TOWERS

This is where the unwanted heat in a facility ends up. A large fan feeds the unit with air. The air meets with the oncoming condenser water. From the direct contact, the condenser water loses heat to the air. The condenser water goes back to the condenser the cycle continues. These open-topped devices come in many designs depending on many factors. Examples are cross flow, counter flow, natural draft and mechanical draft. Stay with us for a coverage of these designs in upcoming posts.

This is a good way of settling the cooling tower vs. chiller confusion. However, if you still need more details about the water-cooled chiller components and operation, reach out to our team and you will get help.

HOW DO I CHOOSE BETWEEN THE TWO?

The cooling capacity is the main guideline for the choice of chiller. Equally crucial is the balance between operating costs and capital costs.

Some clients will base their buying decision on initial cost. However, a value-based option considers both operational cost and initial cost. To determine the initial cost of each option, add the costs for both contractor and equipment. For the water-cooled chiller, remember to add cooling tower.

When it comes to life cycle cost, you have to consider both purchase cost and operating cost.

When you evaluate each of the two chillers this way, you are able to determine its total cost. What you must note is that water-cooled chillers normally appear more valuable if you ignore first cost and water cost. However, it is only after you look at the broader costs that the true picture appears clearly.

CONCLUSION

Energy cost remains a major consideration in any powered equipment. Energy saving measures are being implemented everywhere.

While the chiller has direct impact on energy usage, there are other factors to consider. While the water-cooled chiller may be more energy efficient, it receives stiff competition from air-cooled chiller in terms of installation cost, maintenance cost, number of equipment and several other aspects.

Most importantly, air cooled chillers avoid water consumption so they are ideal alternative in areas with water scarcity or areas with cheap energy but costly water fees.

Have you made your choice already? Give us a mail today for the most specialized and customized attention.

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it.