Permanent magnets can be natural products, also known as natural magnets, or artificial (the strongest magnet is Ndfeb magnet). With wide hysteresis loop, high coeruleity and high remanence, once magnetized, it can maintain a constant magnetic material.

Also known as permanent magnetic materials, permanent magnet is a kind of hard magnetic materials.

In application, permanent magnet operates in the second quadrant of the demagnetization portion of the depth magnetic saturation and magnetization magnetic rayback line.

Permanent magnets should have the highest coercing force OF Hc, remanence Br and maximum magnetic energy (BH)m to ensure maximum magnetic energy storage and stable magnetism.

Alloy permanent magnetic material

Including rare earth permanent magnetic materials (NdFeb Nd2Fe14B), SmCo, AlNiCo

Ferrite permanent magnet material

(Ferrite) By production process

According to different production processes, it can be divided into sintered ferrite, bonded ferrite and injection ferrite, which can be divided into equal and different magnets according to different orientation of magnetic crystals.

These are the main permanent magnetic materials on the market at present. Some of them cannot be phased out due to production process or cost, such as Cu-Ni-Fe (cu-ni-fe), Fe-Co-MO (Fe-Cobalt-molybdenum), FE-co-V (Fe-cobalt-vanadium) and MnBi (Manganese-bismuth).

Rare earth permanent magnetic material:

Rare earth permanent magnetic material (NdFeb Nd2Fe14B) :

According to the different production technology is divided into the following three

Bonded NdFeB

-- Bonded NdFeb is a complex permanent magnet made of ndFeb by evenly mixing the ndFeb powder with binder such as resin, plastic or low melting point metal, and then by compression, extrusion or injection molding.

The product can be formed once without secondary processing and can be directly made into a variety of complex shapes.

Bonded NdFeb in all directions are magnetic, can be processed into ndFeb compression mold and injection mold.

High precision, excellent magnetic properties, good corrosion resistance, good temperature stability.

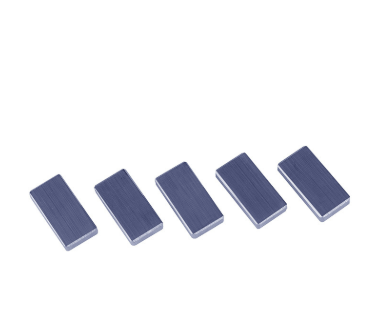

Sintered NdFeB

-- Sintered NdFeb permanent magnet is made by smelting after being ground into powder by air flow. It has a high coerce value and extremely high magnetic property. Its maximum magnetic energy product (BHmax) is more than 10 times higher than Ferrite.

Its own mechanical properties are quite good, can be cut and processed in different shapes and drilling holes.

The maximum operating temperature of high performance products can be up to 200℃.

As its material content may easily lead to corrosion, the surface must be coated differently according to different requirements.

(such as zinc, nickel, environmental zinc, environmental nickel, nickel copper nickel, environmental nickel copper nickel, etc.)

Very hard and brittle, high diamagnetism, high cost/performance ratio, not suitable for high operating temperatures (& GT;

200 ℃).

Injection molded NdFeB (Zhusu NdFeB)

Thin-walled rings or thin magnets with extremely high precision and easy to be made into anisotropic complex shapes

Sintered ferrite

The main raw materials of Sintered Ferrite include BaFe12019 and SrFe12019, which are divided into equal-square and hetero-square magnets according to the orientation of magnetic crystals.

Due to its low price and moderate magnetic properties, it has become a widely used magnet.

Ferrite magnet is made by ceramic process. It is also a hard and brittle material. Due to its good temperature resistance and low price, ferrite magnet has become a widely used permanent magnet.

Rubber magnetic

Rubber Magnet is a kind of ferrite magnetic material series. It is a soft, elastic and warped Magnet made by binding ferrite powder and synthetic Rubber through extrusion molding, rolling molding, injection molding and other processes.

It can be processed into strip, roll, sheet and various complex shapes.

Rubber magnets are composed of magnetic powder (SrO6Fe2O3), polyethylene (CPE) and other additives (EBSO, DOP), etc., which are manufactured by extrusion and calendroning.

Rubber magnetic materials can be of the same or different sex, it is made of ferrite magnetic powder, CPE and some trace elements, can be bent, twisted, coiled.

It can be used without more mechanical processing, and can also be shaped according to the required size. Rubber magnetic can also be used according to customer requirements to cover PVC, back glue, UV oil, etc.

Its magnetic energy product is between 0.60 and 1.50 MGOe.

Applications of rubber magnets: fridges, message racks, fasteners that fasten objects to metal bodies for advertising, etc., magnets for toys, teaching instruments, switches and sensors.

Mainly used in micro special motor, refrigerator, disinfection cabinet, kitchen cabinet, toys, stationery, advertising and other industries.

Aluminum nickel and cobalt

AlNiCo was the first permanent magnet to be developed. It is an alloy of aluminum, nickel, cobalt, iron and other trace metal elements.

According to different production processes, Sintered AlNiCo and Cast AlNiCo are divided.

The shape of the product is mostly round and square.

The casting process can be produced into different sizes and shapes;

Compared with casting process, sintered product is limited to small size, the blank size tolerance produced by it is better than that of casting product, the magnetic property is slightly lower than that of casting product, but the machinability is better.

In permanent magnet materials, the casting al-Ni-Co permanent magnet has the lowest reversible temperature coefficient, and the working temperature can be as high as 600℃.

Al-ni-co permanent magnet products are widely used in various instruments and other applications.

Samarium cobalt

SmCo was divided into SmCo5 and Sm2Co17 according to the composition, which were the rare-earth permanent magnets of the first generation and the second generation respectively.

Its development is constrained by the scarcity and high prices of its raw materials.

SmCo, as the second generation of rare earth permanent magnets, not only has high magnetic energy product (14-28MGOe) and reliable coerce, but also shows good temperature characteristics in rare earth permanent magnets.

Compared with Neodymium iron boron, samarium cobalt is more suitable for working in high temperature environment.

Permanent magnets are widely used in dry electronics, electrical, mechanical, transportation, medical and daily necessities and other fields.

Permanent magnets such as loudspeakers and telephone receivers;

The magnetic system of an electricity meter;

Magnetic poles in generators and permanent magnet motors;

Permanent magnetic components (such as permanent magnetic chuck of surface grinding machine), magnetic suspension system and magnetic bearing used in machine manufacturing;

Magnetic separation system, magnetic separation, magnetic water purification system, magnetron, proton accelerator magnetic system.