In the pharmaceutical industry, the temperature control system, emulsion cooling, suspension heating,plasma heating, citric acid heating, various medication liquid heating, cooling, condensation, sterilization,double-wall plate heat exchangers and plat-shell heat exchangers are often used.

Applciation

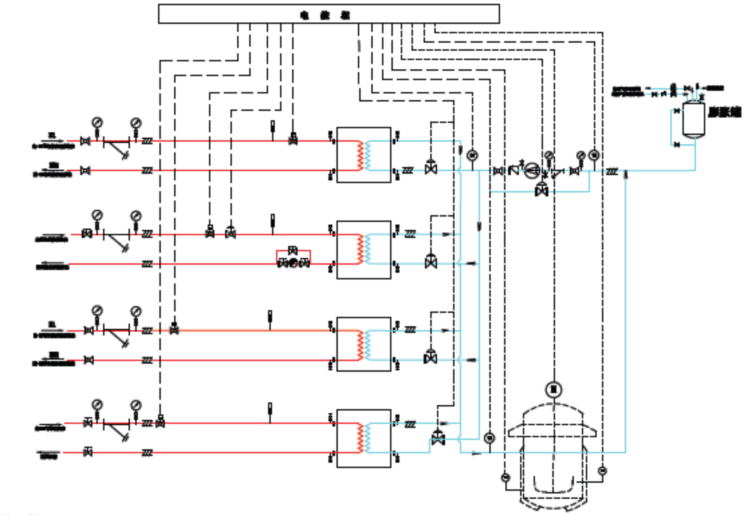

For example, in the temperature control system of pharmaceutical intermediate synthesis reaction kettle, temperature requirements based on actual chemical reactions,the reaction kettle can choose the hot medium of -15°C, -60°C, 165°C, 180°C to heat or cool. According to requirements of temperature rise, temperature drop, and heat preservation during the reaction process, the control-temperature program is set.By controlling the flow rate of heating or cooling medium, the heat or the cold is transmitted to heat transfer oil on the shell side through plate and shell heat exchanger. Thereby controlling the temperature required for the reaction in the reactor kettle.

The reactor kettle controls the temperature rise and fall of reaction materials through using shell form. The temperature control deviation is ±0.5 °C.

The heat exchanger operating parameters:

| Medium | Temperature℃ | Pressure MPa | |

| Shell Side | Heat transfer oil | -15~160 | 1.0 |

| Heating Side | water vapor | 160 | 0.5 |

| Cooling Side | Ethylene glycol aqueous solution | -60~50 | 0.5 |

Advantages of temperature control assembly device:

◆ Temperature control accurate

◆ Small footprint

◆ Low energy consumption