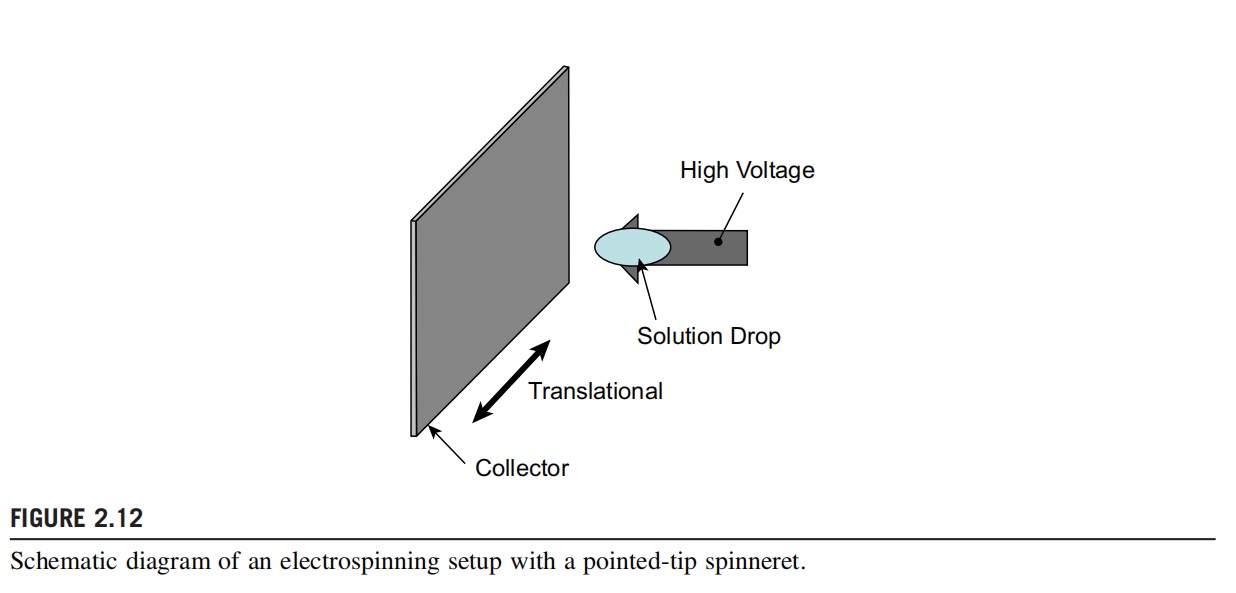

POINTED-TIP SPINNERET

Using a pointed tip instead of a needle, Sun et al. (2006) reported a breakthrough in the electrospinning process. A schematic diagram of the pointed-tip spinneret is shown in Fig. 2.12. The group was able to form fine patterns using electrospinning by depositing fibers at the stable region of the electrospinning jet. The distance between the tip and the collector in this setup was less than 3 mm. To allow for the solidification of the fibers and the stretching of the jet to the nanometer diameter level, the solution source has to be sufficiently small. A tungsten tip of 25-mm tip diameter was used and the polymer solution was transferred to the tip by immersing and pulling the tungsten electrode in and out of the polymer solution. At a distance of 1 mm from the tip to the collector, a 1-kV voltage was sufficient to initiate the electrospinning process. Using a movable collector at a speed of 20 cm/s, straight-line nanofibers were constructed with resolution of up to 25 mm. However, this method shows its disadvantages. The small amount of polymer solution that can be spun at one time means that there is a limitation on the length and the production rate of the nanofiber that can be fabricated. Nevertheless, this method may still be useful in applications such as sensors or 1D polymer transistors where the fiber can be deposited over specific conducting electrodes.