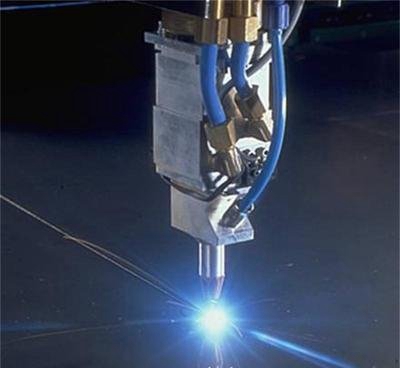

The pull welding method is not difficult for experienced welders, but it is always manual, and the weld bead may not be straight enough and the sheet is deformed. For high-end welding surfaces, the weld bead must be straight and the sheet is not deformed. At this time we can use automatic laser welding.

What are the advantages of laser welding?

1. The amount of heat input can be minimized. The metallographic range of the heat affected zone is small, and the deformation caused by heat conduction is also the lowest.

2. The laser beam can be focused in a small area to weld small and closely spaced parts.

3. The range of weldable materials is large, and various heterogeneous materials can be joined to each other.

4. Easy to automate high-speed welding, can also be digital or computer controlled

5. When connecting thin or thin wire, it will not be easy to melt back like arc welding.

6. Not affected by the magnetic field (arc welding and electron beam welding is easy), can accurately align the weldment.