Air Filtration

Although the traditional fiber air filtration materials can effectively intercept the micron solid particles, the filtration efficiency of the submicron solid particles is low. Nanofibers have the characteristics of small diameter and large specific surface area, which can further enhance the interception of suspended particles. By electrospinning technology system of the preparation of nanometer fiber membrane with good fiber uniformity, controllable pore size distribution, the characteristics of the structure can be adjusted, according to the actual use of the environment demand to choose different polymer materials, which could be prepared for the different particle size of solid particles of high-efficiency low resistance air filtration material, do the special environment of application scenarios have larger development prospects.

· High-Temperature Filtration

· PM2.5 Masks

· High-Efficiency Cartridge Filter

· Haze Screening

· HEPA Filter

· Air Conditioning Filter

1. Application of nanofiber membrane masks

The production principle of the nanofiber air filter is different from that of melt-blown cloth. Contrast melt-blown fabric with air drawing process, nanofiber air filter material using electrostatic wiredrawing, the fiber is finer, and the new product upstream materials will not be limited to polypropylene, as long as it is able to dissolve in the solvent of polymers, including polyurethane, eps olefins, polystyrene, etc. It can be used for textile, much lower production cost than traditional melt-blown cloth.

Nanofiber membrane adopts advanced electrospinning nanofiber technology, and the pore diameter of the nanofiber membrane is about 100~500nm. Compared with the fiber prepared by the melt-blown process, the pore diameter is smaller and the antibacterial property is better. It effectively blocks filtering dust and PM2.5 particles with filtration efficiency up to 99.99% and effectively inhibits more than 650 bacterial viruses such as influenza virus, MERS, SARS, and bacteria.

A. Nanofiber membrane replaces melt-blown cloth as the core filter layer of masks, with the following advantages:

1) The resistance, BFE, PFE, etc. are superior to the melt-blown cloth.

2) Instead of relying on electrostatic adsorption, physical interception is adopted, relying on the principle of physical pore filtration, that is, finer 'mesh' is used to achieve filtration effect.No static electret treatment is required, longer protection effect, no static disappears.

B. Nanofiber film melt-blown composite

1) Melt-blown cloth composite nanofiber processing, easily on 95+, stable 95+, to solve the export problem, easily oily, salt test!

2) Through equipment processing up to 95, 99, solve the problem of low filtration efficiency melt-blown inventory backlog, effective use of existing resources, and can increase the profit of many times! (At present, the price of low-quality melt-blown cloth on the market falls to about 1,415 USD. After processing the melt-blown cloth with the Qingzi Nano production line, it can be sold directly according to 95+ and 99+ melt-blown cloth, and there is no static electricity to disappear. Customers do not need to worry about the product being randomly inspected and disqualified after export.)

3) The processing cost of one ton of melt-blown cloth is the only US $849~ US $1415!

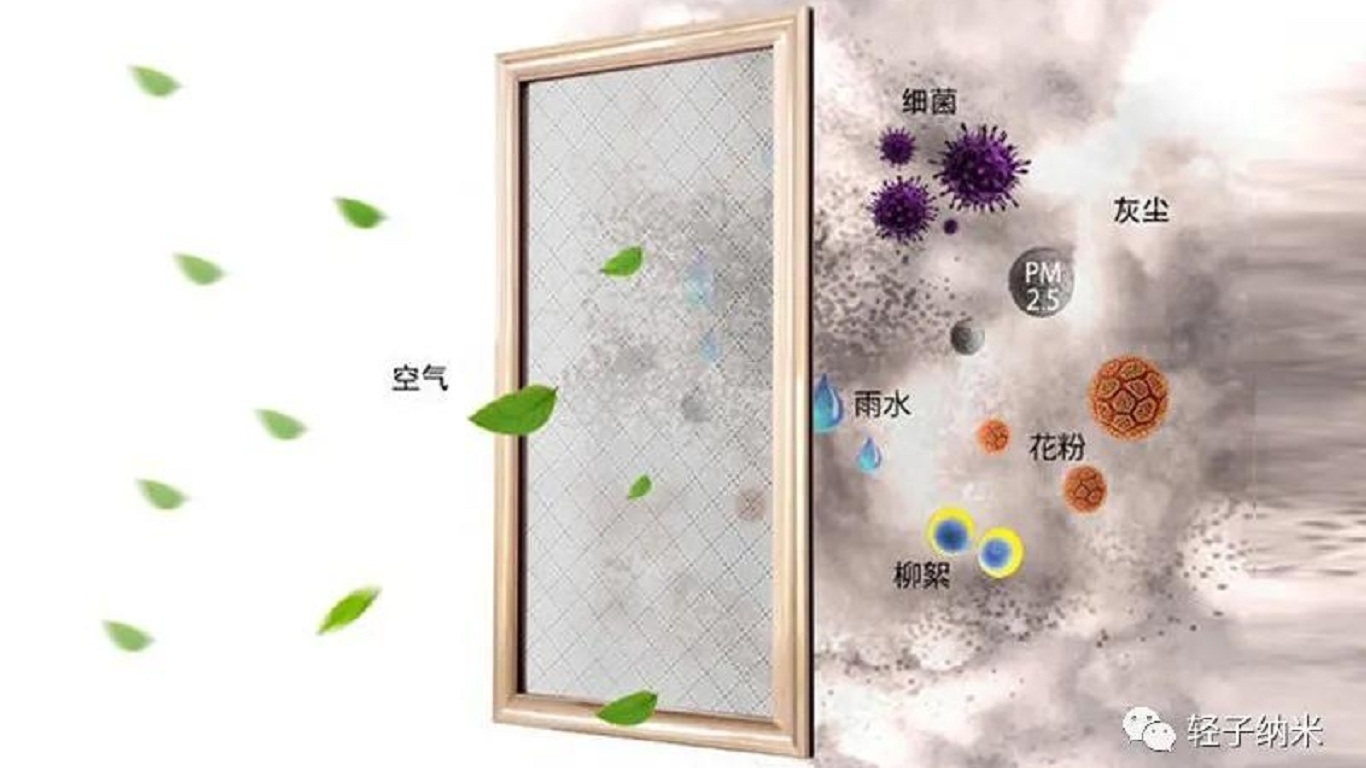

2. Application of nanofiber membrane window screen

Although we can't change outdoor air pollution, we can make indoor air safer.

The haze prevention window screen made of sandwich nanofiber film can simultaneously have five filtering mechanisms, such as screen, inertial collision, Brownian motion, interception, and electrostatic effect, etc., with low wind resistance and good haze prevention effect. Can be widely used in home protection, office buildings and commercial air environment improvement, can effectively block the air including bacteria, PM2.5, dust, pollen, automobile exhaust particles, and other toxic and harmful substances, while ensuring the ventilation and lighting of the building interior, truly build a healthy, ventilated and breathable "nano barrier"!

Ordinary window screens can only protect the house from insects. Nanofiber membrane window screens are dust-proof, smog-proof, breathable, and do not need to close the windows all year round. They can catch smog and PM2.5, pollen, dust, bacteria, and rain. Most importantly, it prevents mold and mold allergens from entering the house, which is often accessed through open windows and can cause dangerous diseases.

3. Application of nanofiber membrane air conditioning

Does staying at home mean the air you breathe is clean? In fact, when the air conditioner is turned on, the room immediately turns into a germ chamber.

A multi-functional nano air filter can make the air conditioner at home into an air freshener. Ordinary filters use only fiberglass or electrostatic composites, but they do not kill bacteria or filter organic compounds. The air filter made by using the advanced electrospinning nanofiber technology, combined with the electrostatic fiber and activated carbon in the nanofiber, can maintain the airflow of cool air and carry out efficient filtration at the same time. It kills bacteria and filters pollutants below PM2.5, as well as volatile organic compounds such as methanol, acetone or benzene. Compared with the electrostatic filtration technology, the air conditioning filter prepared by the nanofiber technology has the advantages of no electrostatic dissipation and durability.

4. Nanofiber membrane air purifier

An air purifier removes particles that can be carried around in a room when the door is open or when the clothes are worn. The purifier circulates the air inside the room.

The nanofiber membrane can be used as the core filter material of HEPA filter screen, filter cartridge, and vehicle air conditioning filter in air purifiers. It can greatly reduce the aperture of the filter paper, greatly increase the specific surface area, and can intercept more fine particles on the surface of the filter paper, changing the filtration mechanism from deep filtration to surface filtration. In a harsh environment, it can still maintain efficient filtration, and because the aperture is small, it is blocked from pollutants floating on the surface, easy to clean, prolong the service life.

Nanofiber technology provides the highest filtration efficiency at the lowest voltage, which has the advantages of low power consumption, low noise, and no static electricity dissipation compared with other technologies.

In terms of preparation methods, nanofiber layers can be synthesized in various ways, either on the upstream or downstream surface or as the intermediate layer of the composite structure.

For more information, please click the following link or add customer service WeChat consultation:

https://www.qingzitech.net/nanofiber-mask-material-production-equipment

Please scan the code directly to add Qingzi customer service staff WeChat: