Flammability and toxicity are the two evaluation indexes of safety. In general the lower the flammability of a refrigerant is, the larger its GWP. R32 is classified as 2, meaning it is a mildly flammable refrigerant, while R290 has a higher flammability and is classified as 3.

The toxicity class of R32 is equal to current refrigerant like R410A and R22 and is classified as level “A” – lower toxicity.

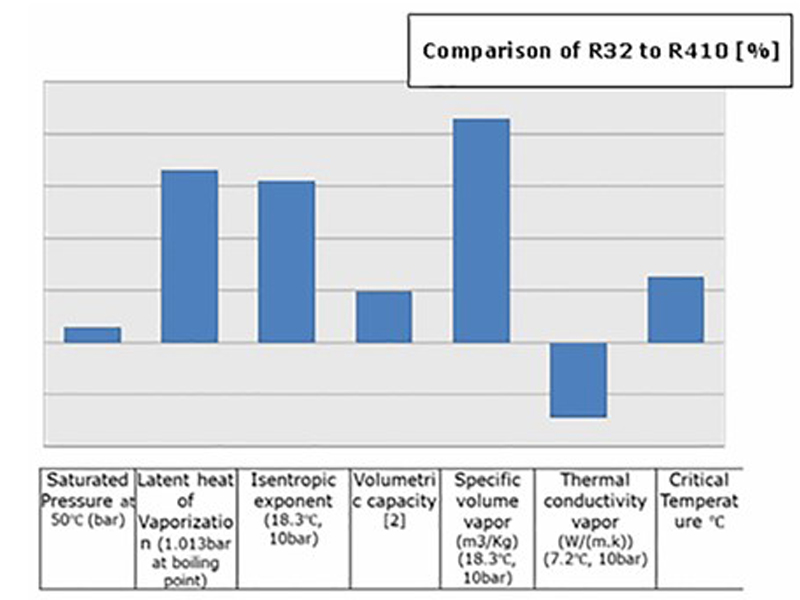

Thermodynamic property has a big impact on system and compressor performance. The figure 1 is a short summary of the comparison between R32 and R410A.

Comparison of R32 with R410

Saturated pressure: R32 has a similar pressure as R410A. This can ease the development on an R32 system based on an R410A platform.

Critical temperature: R32 has a higher critical temperature which yields a higher COP.

Latent heat of vaporization: The heat needed to evaporate R32 is greater than that of R410A so that the required mass flow rate per unit cooling capacity is smaller and the COP is higher.

Isentropic exponent: This can impact the pressure ratio of the system and also the discharge temperature. So R32’s pressure ratio is a little higher than R410A.

Volumetric cooling capacity: R32 has got a significantly higher volumetric cooling capacity than R410A, which can help to reduce the system pipe size and increase the efficiency.

Density: R32’s density is much smaller than R410A, so the amount of charge is smaller, and since the GWP is measured per kg, the total climate impact from the refrigerant in the system is even smaller than suggested by the GWP.

From the above mentioned, R410A, R32 has a better system efficiency, and it needs a smaller refrigerant charge. The significant problem is that R32 has a high discharge temperature. Its direct consequence is the oil degradation which can cause various compressor failures like bearing seizure, low system and compressor efficiency. So the discharge temperature should be limited at an acceptable level to make sure that system and compressor could work normally. Usually is to control discharge temperature by refrigerant. Liquid injection could be a good solution for high discharge temperature directly. As shown in Figure 2 a portion of the condensed fluid is injected into scroll through an electronic injection valve, which will absorb the heat of intermediate compressed gas to vaporize. Thus the discharge temperature can be lower down effectively. And the injected mass flow rate can be easily modulated by injection valve.