Selection of Main Equipment and heat pump

The project uses a 10 high temperature machine (7.7KW) +400 vacuum tube project connecting box solar energy + 36KW electric steam generator (capacity 28 liters, rated temperature 151 C, rated evaporation 50 Kg/h)

From May to October, when the weather is clear, 400 vacuum tube solar energy can heat 4 tons of water to above 80 degrees C before 6 p.m., which can fully meet the water demand. When the temperature is low in cloudy or winter, solar energy absorbs the heat of ultraviolet rays when it is in operation, so that the water temperature reaches about 20 C. Then it is heated to 70 C by air power unit. The air power unit is proportioned according to the ratio of 1:2, so a 10P unit.

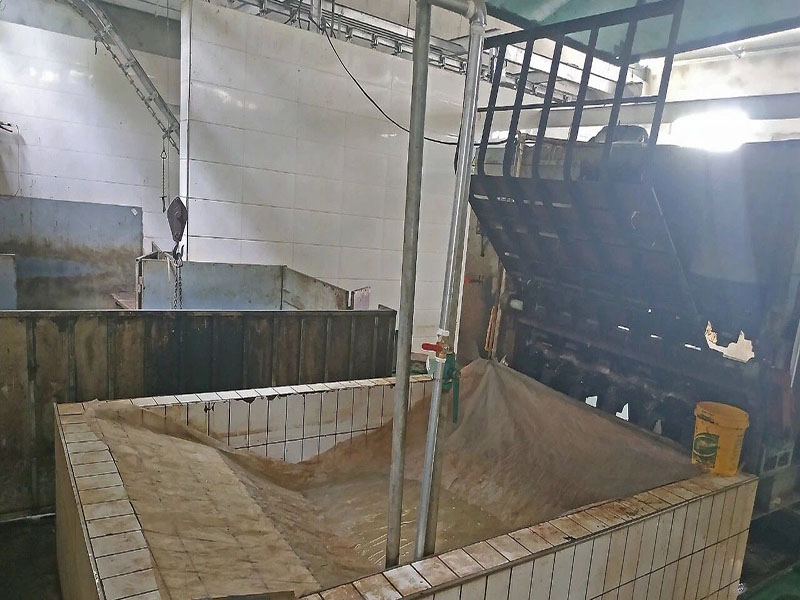

Customers require 2 tons of pool, within 5 minutes to be able to keep constant temperature of 1 C, then one hour of heating is 12 C, the required heat per hour is 2000*1* (60/5) = 24 000 w, that is 24 kw. Considering the slightly greater heat loss in winter, 36 KW electric steam generator is selected.

Steam generator usually does not need electricity at the usual time. It starts 20 minutes before the hot pig is used. Steam generators can be gas, liquefied gas or electricity. Because slaughterhouses are usually far away from urban areas and are not connected with natural gas, and the cost of using liquefied gas is much higher than electricity, so electric steam generators are used when electricity permits.

Because the water tank and the main engine are in one plane, the air energy water pump uses a water pump with a lift of 7.5 meters, a flow rate of 17.4 tons/hour, and an inlet/outlet size of DN65. Because the difference between the top of solar energy and the bottom of the water tank is about 7.5 meters, the solar circulating pump has chosen PUN-201EH with a head of 15 meters, a flow rate of 4.8 tons/hour and a diameter of DN25. Since the water point is on the same plane as the water tank, a hot water pump with a head of 25 meters, a flow rate of 5.4 tons/hour and a diameter of DN25 is adopted, and the pump is controlled by an electronic switch.