Solar battery cells, also known as "solar chips" or "photovoltaic cells", are thin slices of photovoltaic semiconductor that generate electricity directly from sunlight.

A single solar cell cannot be used directly as a power source, solar battery system.

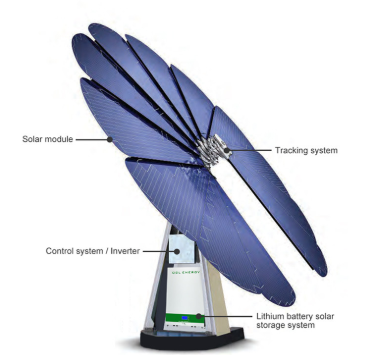

For power supply, a number of single solar cells must be connected in series, parallel and tightly packaged into modules. Solar panels (also known as solar cell modules) are the core and most important part of a solar power system.

Under the action of the electric field of the P-N junction, the hole flows from the P area to the N area, and the electron flows from the N area to the P area. After the circuit is switched on, the current is formed.

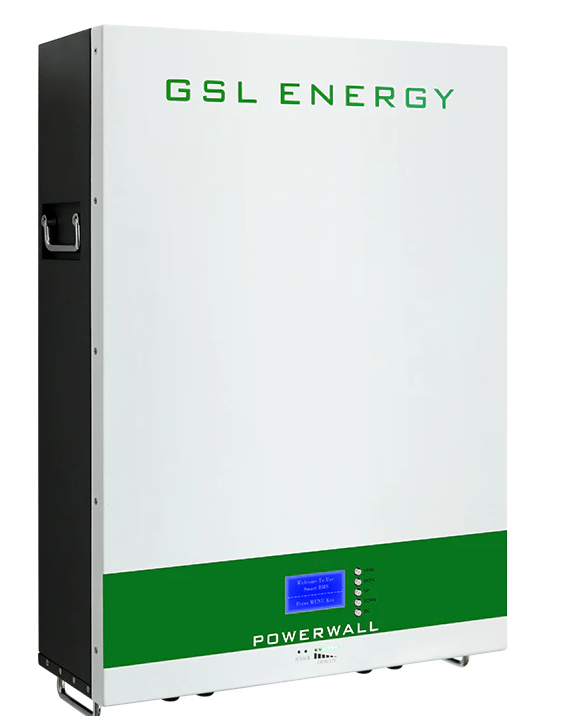

That's how the photoelectric solar powerwall works out.

There are two ways of solar energy product generation, one is light - heat - electricity conversion, the other is light - electricity direct conversion.

(1) The opto-thermal-electric conversion method uses the heat energy generated by solar energy radiation to generate electricity. Generally, the solar collector converts the heat energy absorbed into the steam of working medium, and then drives the steam turbine to generate electricity.

The first process is the light-heat conversion process;

The latter process is the heat-electricity conversion process.

(2) The direct opto-electric conversion method applies the photoelectric effect to directly convert solar radiation energy into electric energy. The basic device of the opto-electric conversion is the solar cell.

Solar energy battery or solar panel is a kind of device that converts solar light energy directly into electric energy due to the photogenic volt effect. It is a semiconductor photodiode. When the sun shines on the photodiode, the photodiode will change the light energy of the sun into electric energy and generate electric current.

When a number of solar panel cells are connected in series or in parallel, a solar array with a relatively large output power can be formed.

With the rapid development of photovoltaic industry, the demand for polysilicon of solar panel grows faster than the development of semiconductor polysilicon. In 1994, the total output of solar panels in the world was only 69MW, while in 2004 it was nearly 1200MW, increasing by 17 times in just 10 years.

Experts predict that the solar photovoltaic industry will surpass nuclear power as one of the most important basic energy sources in the first half of the 21st century.

Solar panel composition and functions:

(1) Tempered glass of solar panel: The function of tempered glass is to protect the main body of solar power generation (such as solar powerwall battery), and the selection of transparent glass is required:

1. High light transmittance (generally above 91%);

2. Super white tempered treatment.

(2) EVA for solar panel manufacturing: fixed toughened glass used for bonding and solar power ( solar battery), the merits of the transparent EVA material directly affect the life of the components, exposed to the air in the EVA aging yellow, thus affect the light transmittance of the component, thus affect the quality of the component's power in addition to the quality of EVA itself, solar panel component manufacturer of laminating process influence is very big, such as EVA adhesive degree is not up to standard, EVA and toughened glass, backplane bonding strength is not enough, which will cause EVA early ageing, affecting the service life of components.

(3) Cell for solar energy panel: The main function is to generate electricity. The main market of power generation is crystal silicon solar cell and thin film solar cell, both of which have advantages and disadvantages.

Crystalline silicon solar panel has relatively low equipment cost, but high consumption and battery cost, but high photoelectric conversion efficiency, so it is more suitable to generate electricity in outdoor sunshine.

Thin film solar cell panel, relatively high equipment cost, but low consumption and battery cost, but the photoelectric conversion efficiency is more than half of the crystal silicon cells, but the low light effect is very good, in ordinary light can also generate electricity, such as the solar cell on a calculator.

(4) Back plate for solar energy panel: Function, sealing, insulation, waterproof.

TPT, TPE and other materials must be anti-aging, most component manufacturers are guaranteed for 25 years, tempered glass, aluminum alloy are generally no problem, the key is with the back plate and silica gel can meet the requirements.

(5) Aluminum alloy of solar powerwall: the protective laminate plays a certain role in sealing and supporting.

(6) Junction box of solar panel: It protects the whole power generation system and plays the role of current transfer station. If the short-circuit junction box of the component automatically disconnects the short-circuit battery string, the most important thing in the junction box of the whole system is the selection of diodes. The corresponding diodes are also different according to the different types of batteries in the component.

(7) Silica gel of solar panel: Sealing function, it is used to seal the junction between components and aluminum alloy frame, components and junction box. Some companies use double-sided rubber strip and foam to replace silica gel. Silica gel is widely used in China, with simple process, convenience, easy operation and low cost.

Monocrystalline solar panels

Polysilicon solar panels

The production process of polysilicon solar panel is similar to that of monocrystal solar panel, but the photoelectric conversion efficiency of polysilicon solar panel is much lower, which is about 12% (The world's highest efficiency polysilicon solar panel, which is 14.8%, was launched by Sharp in Japan on July 1, 2004).

In terms of production cost, compared with monocrystalline silicon solar panel is cheaper, material manufacturing is simple, save power consumption, the total production cost is lower, so it has been developed in large quantities.

In addition, the service life of polysilicon solar panels is shorter than that of monocrystalline solar panels.

In terms of performance-price ratio, monocrystalline solar panels are slightly better.

Amorphous silicon solar panels

Amorphous silicon solar panel is a new type of thin-film solar panel that appeared in 1976. It is completely different from monocrystalline silicon and polycrystalline silicon solar panel in manufacturing method. The process is greatly simplified, the silicon material consumption is low, and the power consumption is lower, and its main advantage is that it can generate electricity in low light condition.

However, the main problem of amorphous silicon solar panels is that the photoelectric conversion efficiency is low, the international advanced level is about 10%, and it is not stable enough. With the extension of time, the conversion efficiency decreases.

Multi-compound solar panels

Multi-compound solar panels are solar panels that are not made from single-element semiconductor materials.

A wide variety of countries have studied, most of which have not yet been industrialized, mainly including the following:

A) Cadmium sulphide solar panels

B) Gallium arsenide solar panels

C) Copper indium selenium solar panels

Test conditions of solar panel wall

(1) Since the output power of solar panels depends on factors such as solar irradiance and solar panel temperature, measurement of solar panels is carried out under standard conditions (STC), which are defined as: atmospheric mass AM1.5, light intensity 1000W/m2, and temperature 25℃.

(2) Under this condition, the maximum power output of solar panel is called peak power. In many cases, the peak power of the module is usually measured by the solar analog meter.

The main factors affecting the output performance of solar panels are as follows:

1) Load impedance of solar energy

2) Sunshine intensity of solar energy

3) Temperature of solar energy

4)Shadow of solar energy

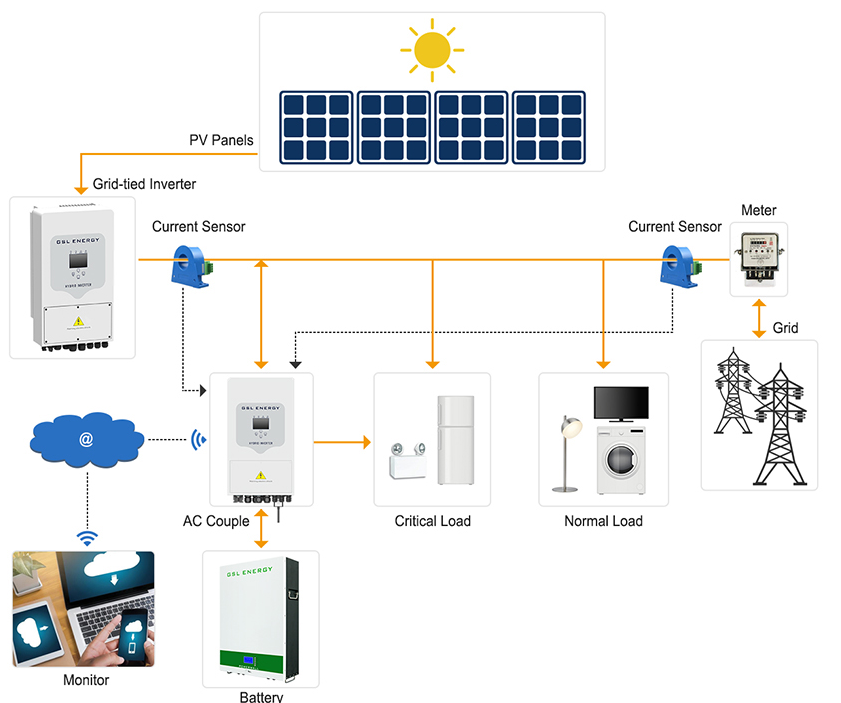

Solar energy generation system is composed of solar panel, charging controller, inverter and battery.

The solar dc system does not include an inverter.

In order to make solar energy generation system provide enough power for the load, it is necessary to choose reasonable components according to the power of electrical appliances.

Taking 100W output power for 6 hours per day as an example, the following calculation method is introduced by professional solar energy storage system manufacturer, GSL group:

1. First, the watt-hour consumption per day (including the loss of the inverter) should be calculated: if the conversion efficiency of the inverter is 90%, when the output power is 100W, the actual required output power should be 100W/90%=111W;

If used for 5 hours per day, the power consumption of solar panel is 111W*5 hours =555Wh.

2. Calculate solar panel: calculate the effective daily sunshine time of 6 hours, and then take into account the charging efficiency and the loss in the charging process, the output power of solar panel should be 555Wh/6h/70%=130W.

Seventy percent of this is the actual power used by solar panels during charging.

Solar energy panel application

I. Solar energy home system

(1) Small and smart solar energy supply ranging from 10-100W is used for military and civilian living in remote areas without power supply, such as plateau, island, pastoral area, frontier post and other military and civilian living power supply, such as lighting, TELEVISION, radio and cassette recorders, etc.;

(2)3-5KW domestic rooftop grid power generation system;

(3) PHOTOVOLTAIC water pump: for drinking and irrigation of deep wells in areas without electricity.

2. Solar powerwall for transportation

Such as navigation lights, traffic/railway signals, traffic warning/sign lights, street lamps, high-altitude obstacle lights, expressway/railway wireless telephone booths, unattended road class power supply, etc.

3. Solar panel for communications field

Solar unattended microwave relay station, optical cable maintenance station, broadcasting/communication/paging power supply system;

Rural carrier telephone photovoltaic system, small communication machine, soldiers GPS power supply, etc.

4. Solar energy system for petroleum, marine and meteorological fields

Solar power system with cathodic protection for oil pipeline and reservoir gate, oil drilling platform life and emergency power supply, ocean detection equipment, meteorological/hydrological observation equipment, etc.

5. Solar energy panel for family lamps and lanterns power supply

Such as solar garden lamp, street lamp, hand lantern, camping lamp, climbing lamp, fishing lamp, black light, rubber cutting lamp, energy-saving lamp, etc.

6. Solar panel for photovoltaic power station

10KW-50MW independent photovoltaic power station, wind-solar (diesel) complementary power station, charging station of various large parking plants, etc.

7. Solar energy for building

It is a major development direction to combine solar power generation with building materials to make large buildings self-sufficient in electricity in the future.

8. Solar panels for others

(1) Supporting facilities for automobiles: solar powered automobiles/electric vehicles, battery charging equipment, automobile air conditioners, ventilator, cold drink boxes, etc.;

(2) Regenerative power generation system for solar hydrogen production and fuel cell;

(3) Power supply for seawater desalination equipment;

(4) Satellites, spacecraft, space solar power station, etc.

Solar panel market

The European Trade commission is likely to propose punitive tariffs of more than 30 per cent on Chinese solar panels in May to protect European producers.

Eu trade commissioner Karel DE Gucht will propose punitive tariffs on Chinese solar panels at a meeting of EU trade representatives on Tuesday and is expected to win support, Reuters quoted diplomats as saying.

In accordance with EU regulations, the temporary tax measures will come into effect by June 6.

However, even if the EU makes a preliminary decision then, there is still room for negotiation with China.

If the negotiations are successful, punitive tariffs of up to five years could be avoided.

The European Commission has launched anti-dumping and countervailing investigations against solar panels imported from China, involving 21 billion euros ($27.6 billion) of Chinese companies' exports to the EU, which has been described by industry insiders as the largest "dual anti-dumping" case in the EU's history.