Glazed flat plate collectors are most suitable where the water temperature is between 10 and 50K above the surrounding air temperature, and so are ideally suited to domestic hot water applications.

The typical construction of a glazed flat plate collector comprises a lightweight metal or polymer tray that contains a layer of insulation (normally glass fibre) to prevent heat loss via conduction through the rear of the collector. The 'absorber' is designed to maximise solar irradiation absorption and is likely to have selective surface coatings to maximise solar gain and minimise re-radiation. For metal absorbers black chrome or nickel coatings are typically used.

A series of waterways bonded to the absorber carry the heat transfer fluid (water or glycol mix) through and away from the collector. The collector has a transparent glass or plastic cover across the whole 'aperture' with a low thermal expansion coefficient and high transmission efficiency to maximise net incoming solar radiation and minimise convection losses. Transmission efficiencies for good quality products are over 90%, absorption efficiencies 95%, emissions (losses) 5% and maximum thermal efficiencies of around 78% over the year.

Copper is commonly used for the tubing in the collector and aluminium or copper for the absorber sheets (with stainless steel being used when aggressive mediums flow through the absorber as in direct-fed swimming pool panels). Polymer and butyl rubber materials are used for applications where the system is designed to carry plain water that may freeze. Whatever tubing is used there must be a good thermal bond between the tubing and the absorber plate. Any connections to the panels together with the immediate fluid loops are likely to be made using mechanical joints rather than soft solder or even brazing as they are subject to high thermal stresses.

To provide good performance, flat plate collectors have inclined mountings or are integrated into an appropriately pitched south facing roof between 30° and 40° to the horizontal.

Evacuated tube collectors

The evacuated tube works in the same way as a thermos flask to reduce the convective and radiative heat loss from the collector back to the environment. They also frequently include some form of focusing reflective surface to provide less dependence on solar position. Since they are more effective per unit area than flat plate collectors they require a smaller installed area and are competitively priced.

The construction of an evacuated tube collector is entirely different to that of a glazed flat plate collector. There are two main types of evacuated tubes. Direct flow evacuated tube collectors, and heat pipe evacuated tubes.

The encompassing tubes themselves can be of a single skin or, more likely, a twin wall Dewar Tube ('thermos flask’) made from borosilicate glass, a glass with high chemical and thermal shock resistance.

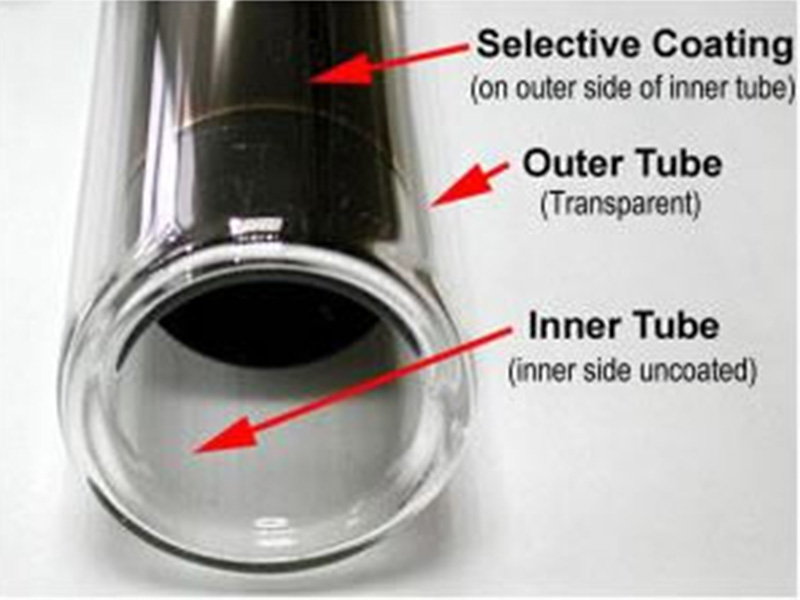

In a common application (known as the ‘Sydney’ tube, after its developer, Sydney University), the outer tube is transparent allowing solar radiation to readily pass through (90%+ transmissivity) and the inner tube is coated with a selective coating (eg aluminium based) that provides high solar absorption and minimal reflection.

Image: Sydney tube.

If a tube develops a leak a silver-coloured barium deposit inside the tube turns a white colour when it reacts with atmospheric oxygen.

In direct-flow evacuated tube collectors, the heat transfer fluid is pumped through a copper ‘U’ pipe in each tube and the U tube is bonded to a circular absorber that is slid inside of the Sydney Tube. Heat pipe evacuated tubes consist of a heat pipe inside an evacuated tube. The pipe, which is a sealed copper pipe, is then attached to a heat transfer fin that fills the tube (this is the absorber plate). Protruding from the top of each tube is a metal tip attached to the sealed pipe. The tubes are mounted, the metal tips at the top, into a heat exchanger or manifold assembly. Water, or glycol mix, flows through the manifold and picks up the heat from the tubes. The copper at the tip of the heat tube can reach well over 150 degrees, able to heat water to 90 °C on hot days and to 60°C in the winter.

A self-limiting capability makes the heat pipe collector very tolerant to extreme temperatures. A large number of variations of the absorber shape are available including those with integral reflectors.

As with flat plate collectors evacuated tubes collect global insolation, however, their efficiency is higher than flat plates at low incidence angles so they can be more effective over a longer period in the day and when the sun is low in the sky. They can be fixed practically flat on the roof or vertically on a façade. Even if the location is not quite directly facing due south, the tubes can be adjusted to maximise solar irradiance.

The completed evacuated tube collectors typically comprise a manifold and a series of glass tubes (typically 20 of 30) connected in parallel.

Image: Evacuated tubes fitted to a roof.

Whilst transmission efficiencies, absorption efficiencies and emissions are comparable to those offered by glazed, flat-plate collectors, the thermal efficiency is higher as a result of the presence of the vacuum with typical values of 83%. The actual increase in efficiency at ‘normal’ operating temperatures, as would be used with a hot water system, are likely to be somewhat less.

The increased efficiency (particularly at higher temperature) will lead to higher stagnation temperatures. This means that the materials associated with an evacuated tube installation must be rated at an appropriately high temperature.

Evacuated tubes are not as sensitive to positioning as flat plates but are more challenging to integrate seamlessly into the fabric of a building.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you’re interesting in heat pump products,please feel free to contact OSB heat pump. We are your best choice.