Solar thermal installations

As with any heating and ventilation installation, specialist knowledge and expertise is required to design, install and maintain solar thermal systems.

For commercial installations on flat roofs it is likely to be cost effective to provide an appropriately designed framework so that there is correct collector tilt and azimuth (orientation). As collectors may be used as part of the fabric it is advantageous to integrate their needs (tilt, orientation, fixing and access) early on in the design process. Flat plate collectors are likely require a higher tilt angle than evacuated tubes.

The solar thermal system

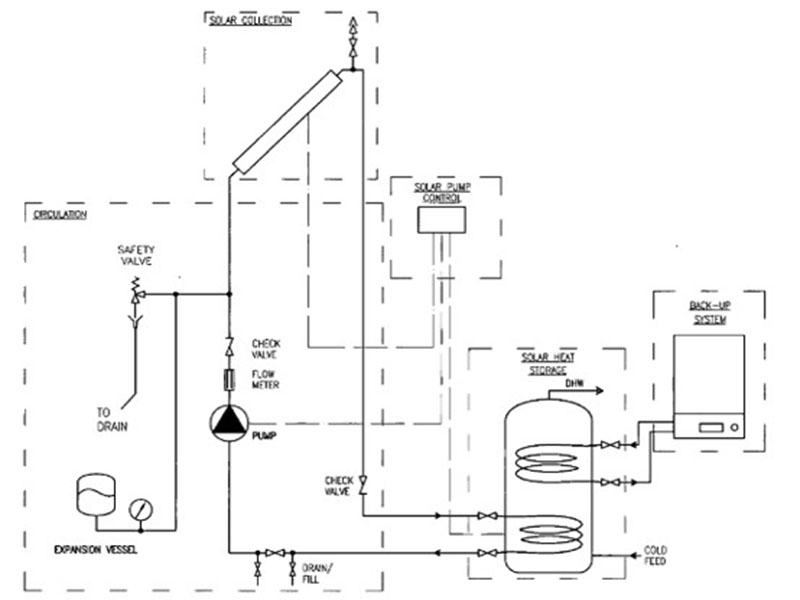

The typical components of an indirect solar thermal system are shown in the diagram below. This diagram and others in this article are simplified and do not show the full controls for efficiency and safety needs however it is essential to note that no means of isolation should be placed between the collector and the safety relief valve.

Image: A closed pumped system.

The water supplying the domestic hot water outlets is potable but the primary water from the solar collectors may be a glycol mix or non-potable water in indirect systems. NB for direct systems (that heat the domestic hot water directly in the collectors) it must be potable.

In many stores, to maximise the heat capacity, and to make water available for space heating, the water drawn off from the solar cylinder can be at a temperature that is too high to pass directly to hot water outlets. Some mixing arrangement, or a secondary, lower temperature will be used to ensure safe temperatures.

The design of the systems and their installation should specifically prevent the following:

Scalding risk from steam or hot water. Failsafe control is required to keep temperatures safe at water outlets.

Freezing of fluids where it might cause damage or block pipes and safety valves.

Accumulation of solids or bacteria. Some water treatment may be needed, particularly in direct systems.

Legionella bacteria developing within the consumed drinking or shower water. The system operation must meet the requirements of HSE Code of Practice L8 for the control of Legionella. This will normally mean a loss in overall seasonal efficiency as auxiliary heating will be required and must be maintained in use.

Degrading of water quality due to contact with materials and fittings during stagnation. The oversizing of systems will make the chances of stagnation more likely.

Backflow or thermo-siphoning of heated water into a cold water cistern.

Disturbance of stratification in the solar storage vessel during normal operation. This will be disturbed in 'sterilisation' cycles.

Loss of dedicated solar storage capacity. Systems that are designed to operate with storage will stagnate if they are run without the storage being available.

Loss of liquid from the system through overflow. Any liquid that is lost has to be replaced. This will affect the composition of the anti-freeze additives and will also allow more oxygen and solids into the system. The expansion vessel should be large enough so that any stagnation does not cause fluid loss through the safety device. In closed systems a heat dump mechanism, typically a radiator, can be used to dissipate heat when the hot water store can accept no more.

Systems in the UK are likely to be either a fully-pumped or drain-back configuration. In climates where freezing is unlikely syphonic systems may be used but there application is unlikely in the UK.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you’re interesting in heat pump products,please feel free to contact OSB heat pump. We are your best choice.