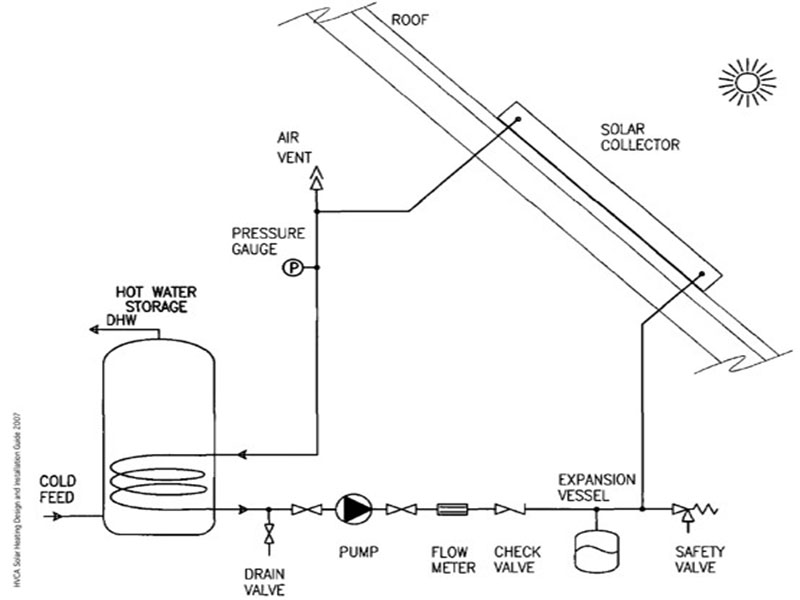

Drainback system

The drainback system uses a differential temperature pump controller to compare the temperature in the collector and the store. If heat is available and needed, the pump will switch on. The pump draws liquid from the bottom of the drainback vessel and pumps it up through the top of the solar collectors to return by gravity to the drainback vessel. When the system is not in use or when there is no call for heat, the pump switches off and the water drains from the collectors into the drainback vessel.

Image: A simple drainback system.

Draining back prevents unwanted reverse circulation and overheating and risks from stagnation but is practically limited to residential-sized applications.

The claimed benefits of a drain back system are:

Gravity is fail-proof and maintenance free.

Water (or a glycol mixture) may be used in the collector loop.

The system is not damaged if the pump fails.

The system cannot reverse thermosyphon at night.

Collector plates are likely to last longer than in a pressurized glycol system.

However there are also disadvantages:

Collectors and piping must be above and slope downwards towards the reservoir.

Larger piping and insulation must be used.

There are relatively large pumping requirements, especially if the design involves multistory buildings.

System and pump controls cost approximately 10% of the solar savings (photovoltaic powered pumps are not strong enough).

Components cost about 10-15% more than a glycol system.

Systems can be noisy.

Thermal stores and combi-systems

A thermal store will be needed to make solar heating practical. For small residential applications this frequently shares the function of the hot water cylinder. With indirect systems a second coil will be in the lower part of the cylinder to exchange the heat from the solar collectors into the potable domestic hot water.

Image: Section through a purpose made solar thermal store.

Larger non-domestic applications will commonly use an additional storage vessel that will act as a preheated feed to the traditional hot water heating system. In the case of a swimming pool installation, the pool itself acts as the thermal store.

Purpose designed thermal stores are becoming increasingly common where the heat from solar panels is used to indirectly preheat water in the store that is then heated directly by the auxiliary heating device (eg a gas boiler).

This water then provides the (non-potable) primary heating water and a coil is immersed in the cylinder to instantaneously provide heat for domestic hot water. These systems are known as 'combi-systems'.

The sizing of the store is as critical as the collectors in ensuring that the maximum benefit is gained from the system. As solar systems become more commonly used, dedicated solar stores (separate from the potable hot water system) are being used in the UK. The size of the associated solar storage tank will depend on the type and frequency of hot water use in the building. Its role is to provide a store for solar heat that is not immediately used by the building. Information from Germany suggests that storage of approximately 50 litres is required per sq m collector area for large-scale installations with reasonably constant weekday use and 60-70 litres per sq m collector area for those where there are consumption free weekdays.

Factors to consider prior to installation

There is a comprehensive list of factors that should be considered prior to installation in the Energy Savings Trust's Solar water heating systems – guidance for professionals, conventional indirect models. These include:

Occupant’s domestic how water usage pattern.

Shading. The seasonal influence of trees and local buildings.

Collector fixing slope and orientation. The limitations of the particular roof, wall or ground fixing.

Collector fixing area, structure and covering. The methods that may be used to fix the collector.

Access to collector location, ensuring safe access for installation and servicing.

Domestic hot water heat sources. To confirm that auxiliary heating is able to coexist and work in conjunction with solar thermal.

Pre-heat storage locations. Ensure that there is the opportunity to integrate appropriate pre-heat facilities (if required).

Secondary water pressure and quality.

Remark:

Some of the articles are taken from the Internet. If there is any infringement, please contact us to delete it. If you’re interesting in heat pump products,please feel free to contact OSB heat pump. We are your best choice.