Spring steel refers to steel that is specifically used to make springs and elastic components due to the elasticity in the quenched and tempered state. The elasticity of steel depends on its ability to artistically deform, that is within the specified range, the ability to elastically deform it to withstand a certain load, and no permanent deformation occurs after the load is removed. The main spring steels are used in a wide variety of applications, such as automotive, locomotive, tractor leaf springs, coil springs, cylinder safety valve springs and some important springs that work under high stress, and severely worn springs. At present, these industries are China's leading industries, and the demand is a considerable amount of data. How can we guarantee the quality of spring steel?

We have summarized the professional performance of spring steel and strict production technical requirements in the production process for many years: performance requirements springs are used under impact, vibration or long-term stress, so spring steel is required to have high tensile strength, elastic limit and high fatigue strength. In the process, it is required that the spring steel has certain harden ability, non-decarburization, good surface quality, and carbon spring steel, that is high-quality carbon structural steel having a carbon content WC in the range of 0.6%-0.9%. Alloy spring steel is mainly silicon-manganese steel, their carbon content is slightly lower, mainly by increasing the silicon content Wsi to improve performance; in addition, alloy spring steel of tantalum, tungsten and vanadium. In recent years, combined with China's resources, and in accordance with the requirements of new technologies fir automobiles and tractors, we have developed new steel grades that incorporate elements such as boron, niobium and molybdenum on silicon-manganese steel, prolonging the service life of springs and improving the quality of springs.

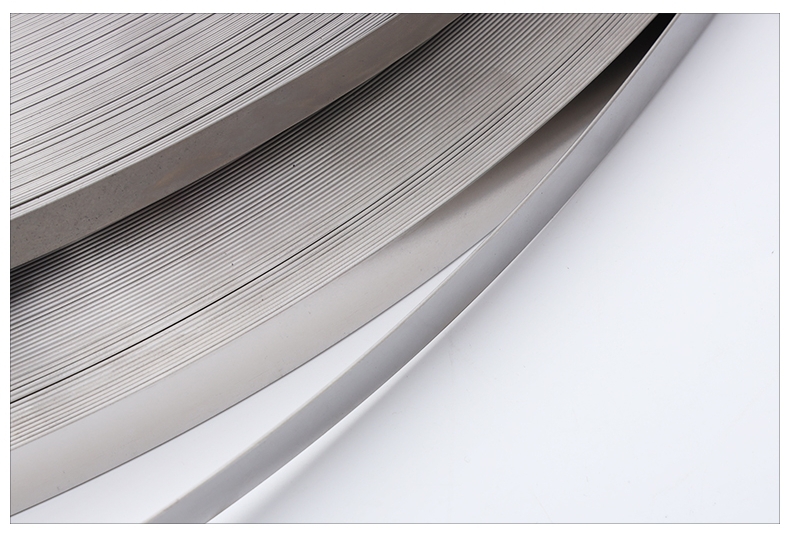

Production Process

Generally, spring steel can be produced by electric furnace, open hearth furnace or oxygen converter; high quality spring steel with good quality or special performance can be refined by electroslag furnace or vacuum furnace. In the spring steel, the main content of carbon manganese, silicon and other major elements is narrow, and the chemical composition must be strictly controlled during smelting. When the silicon content is high, defects such as bubbles are easily formed, and white spots are easily generated when the steel ingot is cooled after the forging. Therefore, the raw materials used for smelting must be dried to remove gases and inclusions as much as possible, and to avoid overheating of molten steel. Spring steel must pay special attention to decarbonization and surface quality during rolling. When the steel surface is severely decarbonized,the fatigue limit of the steel is significantly reduced. For high silicon spring steels such as 70Si3MnA, care should be taken to avoid graphitization. Therefore, the stop roiling temperature should not be too low (>850℃) during hot working to avoid excessive residence time in the temperature range (650-800℃) where graphitization is easier to form. After the spring is made, the shot peening can produce residual compressive stress on the surface of the spring to offset some of the working stress on the surface layer and suppress the formation of cracks in the surface layer, which can significantly increase the fatigue limit oi the spring.