ZHONGYA, a global supplier of solutions for the packaging, printing and slitting machine, has successfully concluded the complete remote installation of a few machines – a procedure that became necessary due to the Covid-19 pandemic.

A full automatic slitter was installed in Greece, a company founded in 2010, which specialises in the production of thermal paper.

Distance not an obstacle

During the installation of this brand-new slitter, performed at the facilities , the distance between the plant and the headquarters of ZHONGYA was not an obstacle. The success of the project is primarily thanks to the considerable involvement of the entire Greece team, together with the support of the ZHONGYA after-sales service department and the local technical assistance team.

“We are very pleased with the remote installation of the slitter. This machine will allow us to continue offering services to all our customers, despite the difficulties of the current global pandemic situation,” says Jim, CEO of Greece Factory.

In an effort to make the lives of customers more uncomplicated, ZHONGYA had set out, well before the start of the COVID-19 pandemic, to facilitate launches and machine operations as strategic key pillars of the company. Presently, and during the past months, this approach has been an enormous success as can be proven by several remote installations.

A higher degree of automation

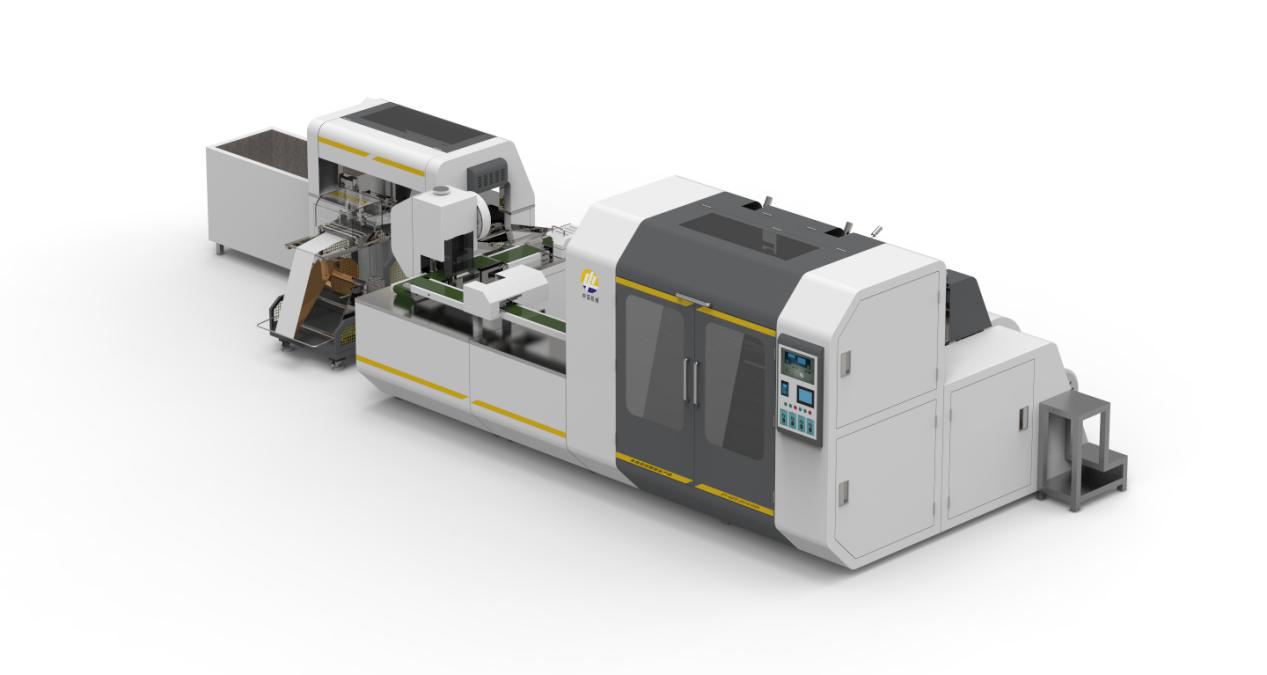

In regard to its line of products, ZHONGYA has been working towards automation for an extended period of time. In particular, the slitting division focuses on automation, in order to differentiate itself from competitors and offer both slitters as well as end of line automation.

In the market, there are more than 100 full automatic slitters, which offer high versatility in the range of materials. With this slitter, quality and quantity are both possible. Operating the full automatic slitter is extremely easy and intuitive, thanks to the enormous work that has been done to offer a pleasant, comfortable and agile interface.