Today, let's learn about the amazing bisected angle in paper box structure design. When we master this method, some seemingly impossible paper box structures can be easily solved!

Bisecting is designed to achieve a structure or a desired design by splitting a single plane angle of a folding paper box. It is widely used in paper tube box or disc box, automatic folding paper box and other box structures that need overlap and other requirements. Bisected angle, is referred to a plane angle of the blank folding paper box, is split into two equal angles by its angle bisector, or a regular plane geometry, is divided into two equal parts by an angle bisector.

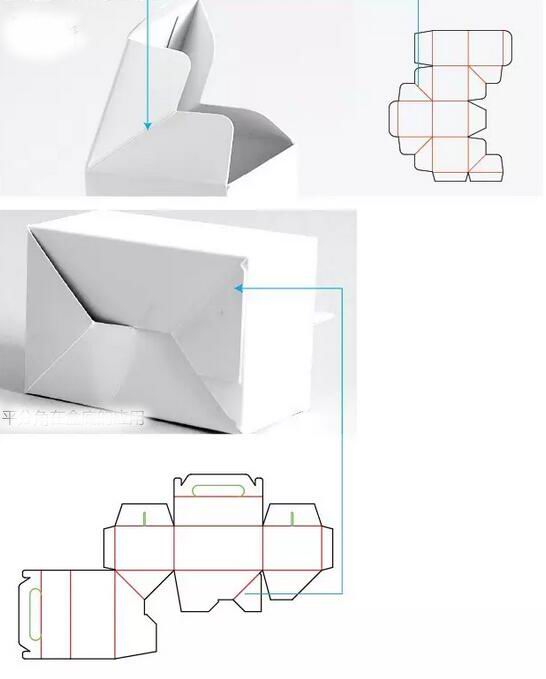

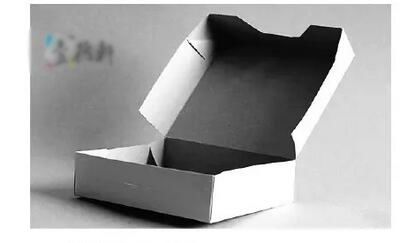

1.The bisecting angle design for the folding tubular box

The use of bisecting angles at the bottom of the paper box

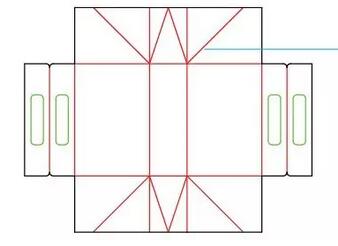

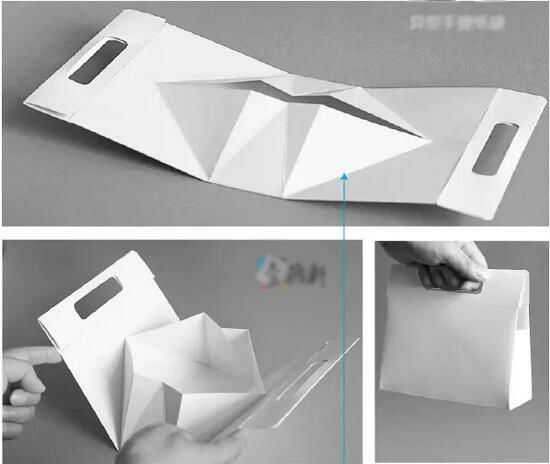

The application of bisecting angle at the side position of paper bag

The application of the bisecting angle at the dustproof wing of paper box

In most cases, the angle bisector is usually used as box folded line, so that in the process of forming or to meet the requirements of other features, folded in half along the angle bisector, its two parts(two half angles or two equal parts) can overlap.

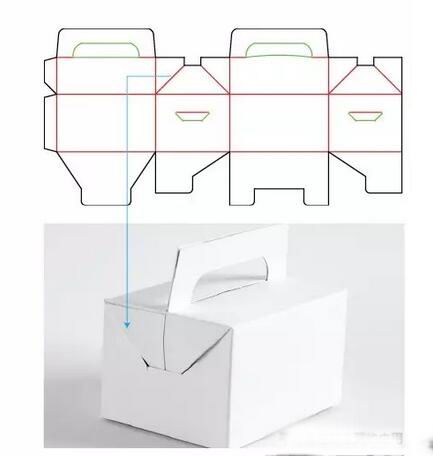

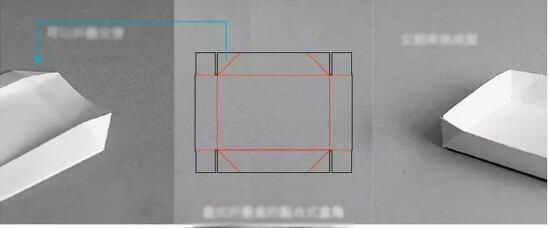

2. The bisecting angle design for the disc box

The four corners of the folding lid and bottom boxes are designed with bisecting angles, can make the two adjacent edges more compact and firm. If not, the corners are loose and not beautiful.

Non-bonded box angle of folding disc box

Bisecting angle design for the corners of the bonded disc box, is to use the bisector of the flap at the corner of the box as half folding line, and two sides of the folding line can overlap completely. Such box structure design, can paste box by automatic machine, folded delivery , reduce the volume and storage, transportation cost.

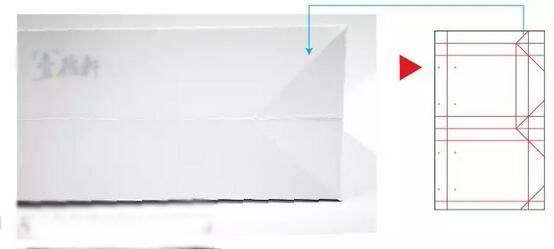

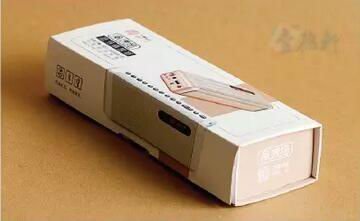

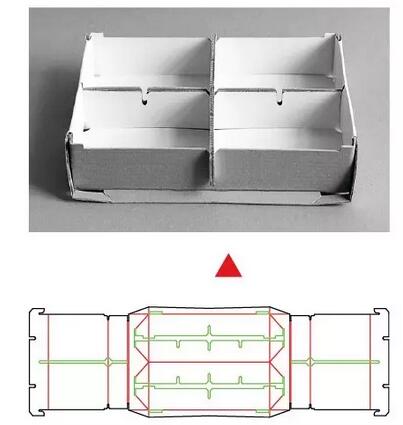

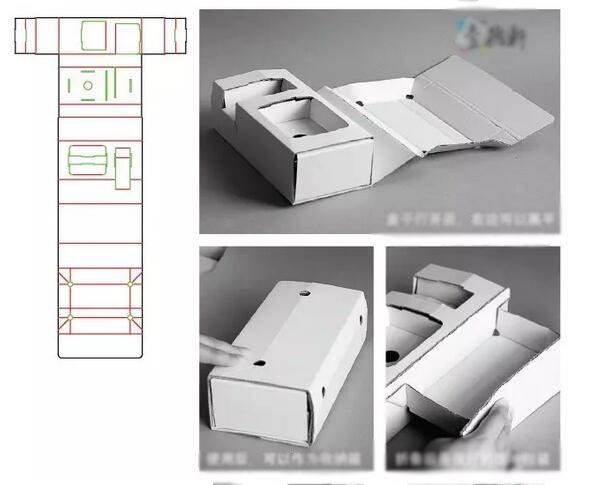

This paper box structure actually use a folding cardboard box in book shape as reference. when warehousing, the boxes are stored in flat, when packing, the box is folded and formed by bisecting angle, the end face of the box is perpendicular to the side and bottom.

The application of bisecting angles in box forming.

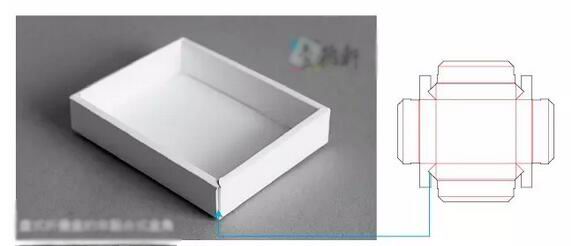

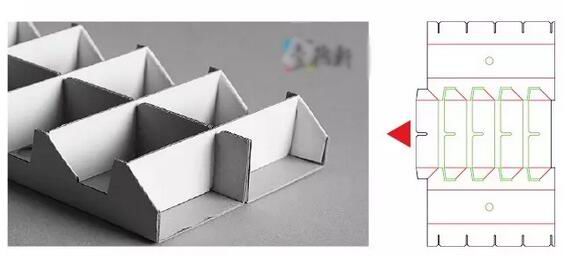

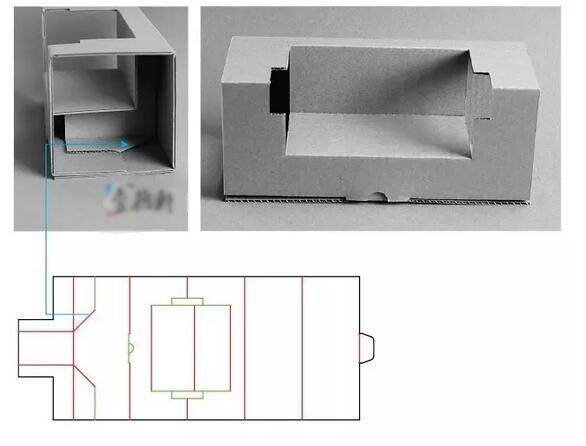

3. The bisecting angle design for the spacing and cushioning

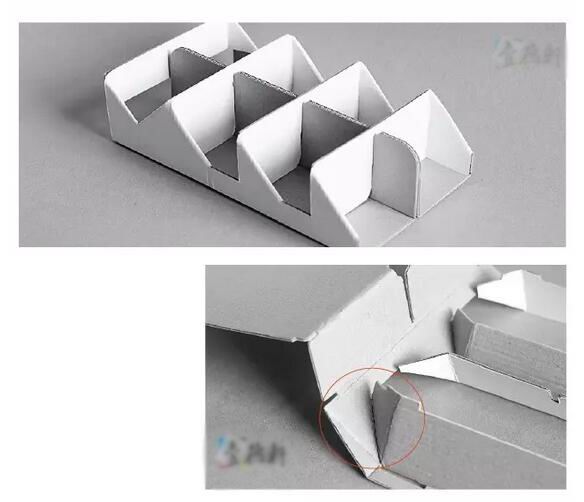

How to ensure that the angle stays the same, when fold a piece of paper into a 90-degree angle? Of course you have to use bisecting angle design. Above cushioning design is the example of the bisecting angle design.

Above spacing design is the most representative example for the bisecting angle design. It can be used as an inner packing to separate products, can also be used as outer packing to carry products.

Many kinds of cushioning structures can be designed with bisecting angle design.

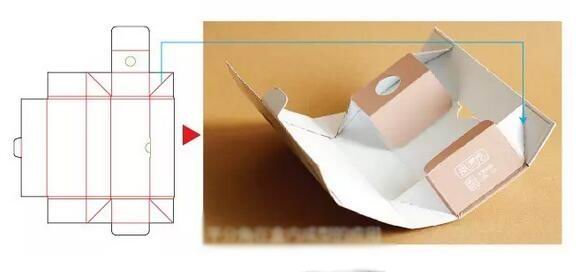

Below is packaging interior structure design for a digital camera, on which bisecting angle design is used very cleverly.

When the box is opened, the right side can be flattened; After use, it can be used as a storage box; After folding ,it is a good cushion packaging.

Such a positive and reverse inlaid structure, if there is no support at bottom, the heavier products cannot be packed. The bisecting angle design is used to solve the support problem, simple folding without glue or other accessories.

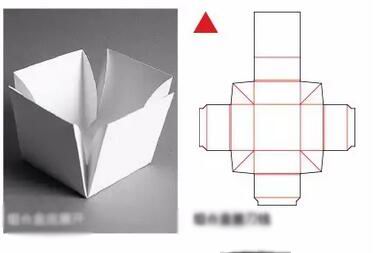

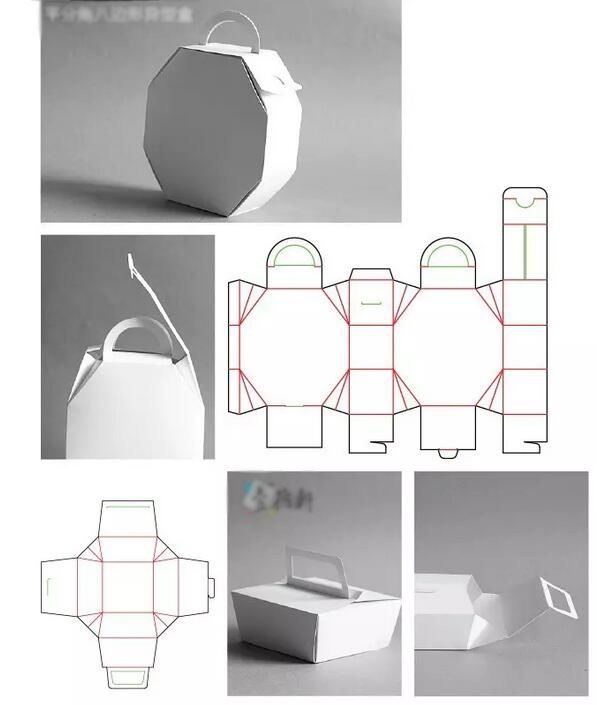

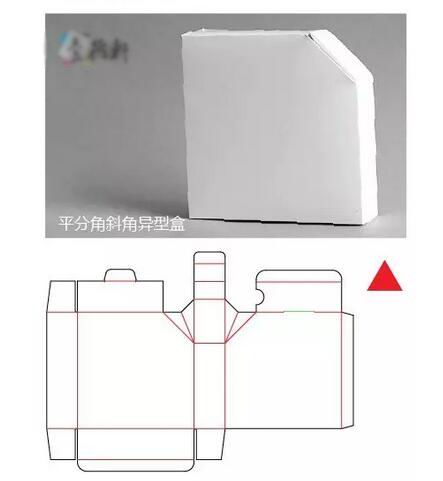

4. The bisecting angle design for the special packaging boxes

The special box structure here refers to a box with a non-rectangular box on the side of the box, such as hexagon, octagon or other box type. Sometimes the bisecting angle is necessary, when the box is folded under the circumstance, that the corner of the box are not cut off.

Using bisecting angle design, all kinds of different special box structures are solved.

This paper bag folds from both sides to the middle, partially glued together with glue, and the middle of the bag does is without glue. When flattening, it is a piece of paper, when standing up, it can be folded into a paper bag by bisecting angle.